-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 01, 2025 06:03

Back to list

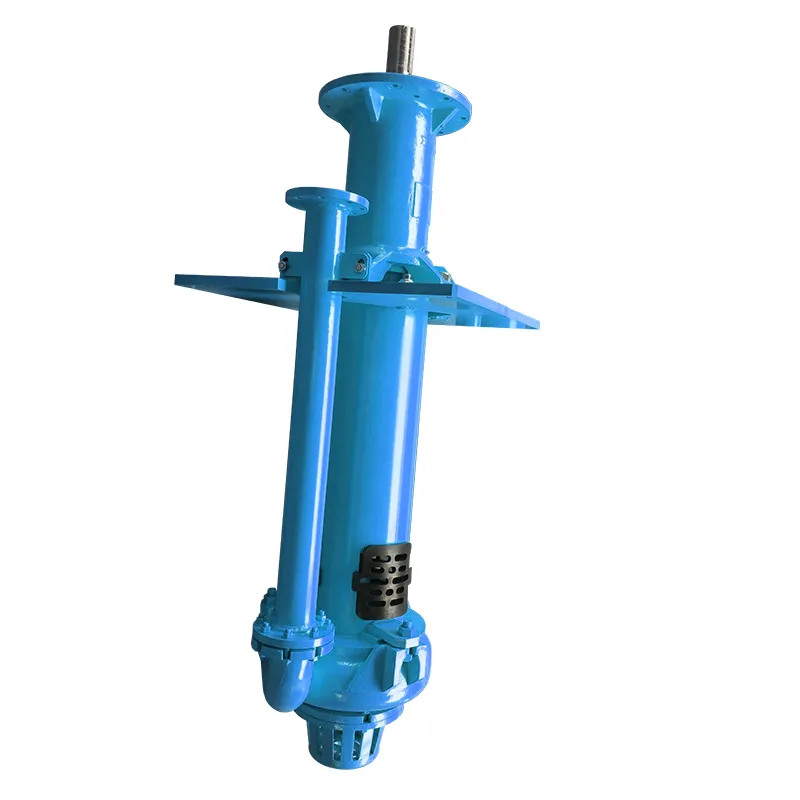

vertical centrifugal pumps

Vertical centrifugal pumps stand as a pivotal component in various industrial applications, engineered to deliver reliability and efficiency in fluid handling tasks. Their unique design and functionality cater to specific operational needs, marking a significant advantage over other pump types. For industries prioritizing space-saving apparatus without compromising on performance, vertical centrifugal pumps emerge as an indispensable asset.

The authority of vertical centrifugal pumps is further reflected in their ability to be customized to meet specific application needs. Manufacturers often provide a myriad of configurations and sizes, allowing for precise fitment into existing systems while optimizing for efficiency and performance. Some models feature multi-stage designs that enhance pressure capabilities, consistently delivering optimal performance even under demanding conditions. From a trustworthiness perspective, the operational reliability of vertical centrifugal pumps is unparalleled. With fewer moving parts compared to other pump types, maintenance demands are minimized, ensuring prolonged operation without frequent interruptions. This reliability is instrumental in critical applications where downtime can lead to significant operational and financial repercussions. Moreover, technological advancements in pump monitoring and diagnostics have further bolstered the trust in these systems. Incorporating intelligent sensors and real-time monitoring capabilities, today's vertical centrifugal pumps allow for predictive maintenance schedules and immediate alerts to any deviations or inefficiencies in operation. This seamless integration of technology and engineering ensures that industries can rely on these pumps for stable and consistent performance. In conclusion, vertical centrifugal pumps epitomize the synthesis of experience, expertise, authoritativeness, and trustworthiness in fluid handling solutions. Whether dealing with standard industrial applications or challenging environments requiring tailored solutions, these pumps offer unmatched efficiency and reliability. Their continued evolution in design and technology underscores their pivotal role in modern industrial operations, cementing their place as a preferred choice for engineers and operational managers worldwide.

The authority of vertical centrifugal pumps is further reflected in their ability to be customized to meet specific application needs. Manufacturers often provide a myriad of configurations and sizes, allowing for precise fitment into existing systems while optimizing for efficiency and performance. Some models feature multi-stage designs that enhance pressure capabilities, consistently delivering optimal performance even under demanding conditions. From a trustworthiness perspective, the operational reliability of vertical centrifugal pumps is unparalleled. With fewer moving parts compared to other pump types, maintenance demands are minimized, ensuring prolonged operation without frequent interruptions. This reliability is instrumental in critical applications where downtime can lead to significant operational and financial repercussions. Moreover, technological advancements in pump monitoring and diagnostics have further bolstered the trust in these systems. Incorporating intelligent sensors and real-time monitoring capabilities, today's vertical centrifugal pumps allow for predictive maintenance schedules and immediate alerts to any deviations or inefficiencies in operation. This seamless integration of technology and engineering ensures that industries can rely on these pumps for stable and consistent performance. In conclusion, vertical centrifugal pumps epitomize the synthesis of experience, expertise, authoritativeness, and trustworthiness in fluid handling solutions. Whether dealing with standard industrial applications or challenging environments requiring tailored solutions, these pumps offer unmatched efficiency and reliability. Their continued evolution in design and technology underscores their pivotal role in modern industrial operations, cementing their place as a preferred choice for engineers and operational managers worldwide.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024