-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

Design and Applications of Vertical Centrifugal Pumps in Various Industries

Vertical Centrifugal Pumps An Overview

Vertical centrifugal pumps are a type of mechanical device widely utilized in various industries for moving liquids from one place to another. They are designed with a vertical orientation, which makes them particularly suitable for applications where space is limited or where the liquid source is below the pump location. This article explores the construction, functioning, benefits, and applications of vertical centrifugal pumps.

Construction and Design

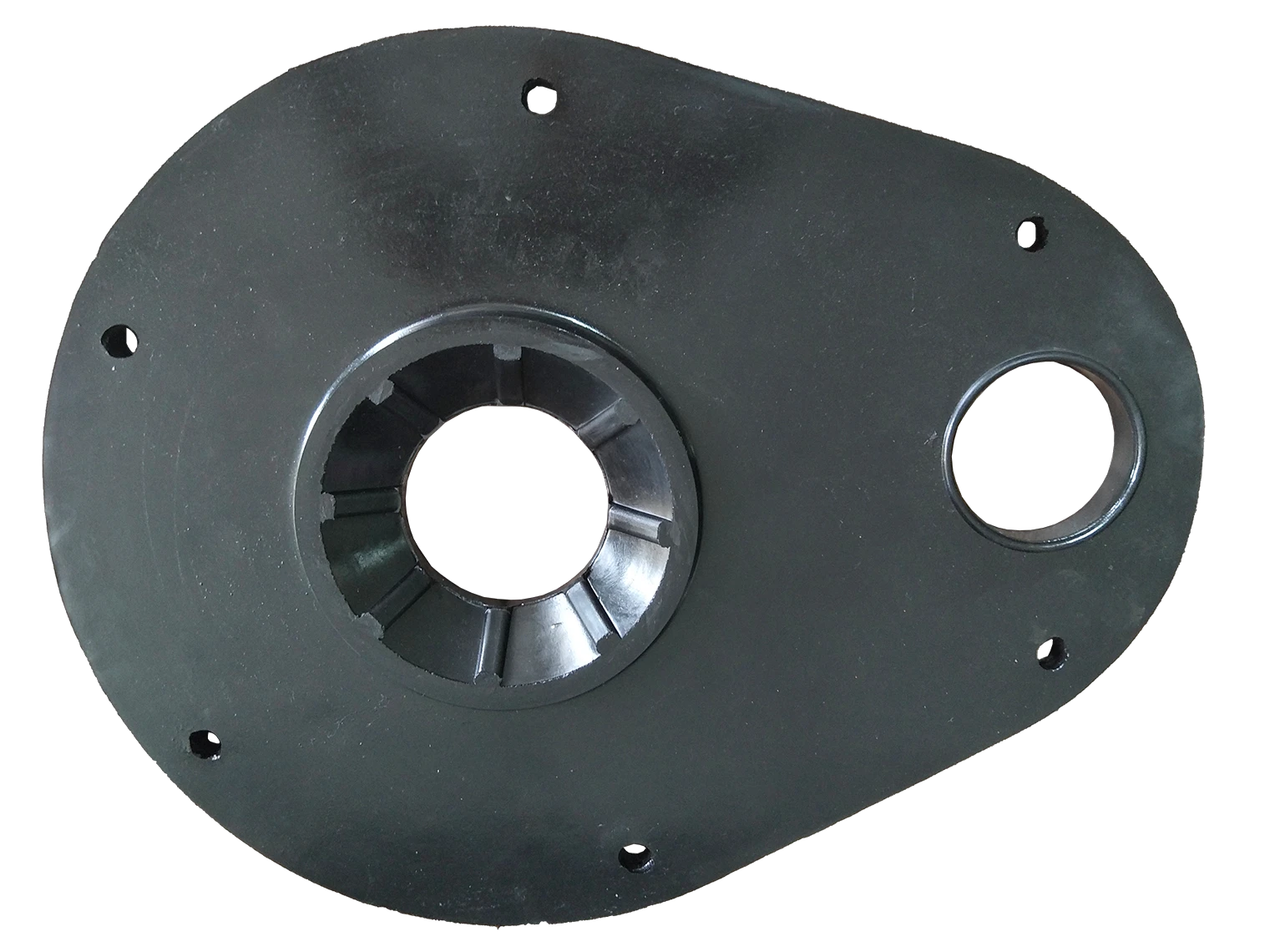

A vertical centrifugal pump consists of several key components the pump casing, impeller, motor, and shaft. The pump casing houses the impeller and directs the flow of liquid. The impeller, typically a rotating disc with blades, is responsible for generating the centrifugal force required to move the liquid through the pump. The motor provides the necessary power to rotate the impeller, while the shaft connects the motor to the impeller.

One of the distinguishing features of vertical centrifugal pumps is their vertical shaft arrangement. This design allows for a compact installation footprint, which is particularly advantageous in environments where horizontal space is scarce. Additionally, these pumps are often designed with a wet pit configuration, enabling them to be submerged in the liquid they are pumping, thus enhancing their ability to handle products containing more significant levels of solids or debris.

How They Work

The operation of a vertical centrifugal pump is based on the principle of centrifugal force. When the motor activates the shaft and impeller, the impeller begins to rotate, causing the liquid within the pump casing to move. As the impeller spins, it imparts kinetic energy to the liquid, converting it into velocity and making it exit the pump through the discharge outlet.

The design of the impeller plays a crucial role in determining the pump's efficiency and flow characteristics. Different impeller shapes can be used based on the application's requirements, such as handling varying volumes and types of liquids (including corrosive fluids, slurries, and hot liquids).

Benefits of Vertical Centrifugal Pumps

Vertical centrifugal pumps offer numerous advantages that make them a preferred choice for many applications

1. Space Efficiency Their vertical design requires significantly less floor space compared to horizontal pumps, making them ideal for installations in tight areas.

vertical centrifugal pumps

3. Lower Risk of Cavitation The vertical configuration can help mitigate issues related to cavitation, which occurs when the pressure in the pump falls below the vapor pressure of the liquid, leading to potential damage.

4. Efficient Operation Vertical centrifugal pumps usually provide high efficiency and reliability, ensuring optimal performance over extended periods.

5. Ease of Maintenance Many vertical pumps are designed for easy access to internal components, simplifying maintenance and reducing downtime.

Applications

Vertical centrifugal pumps are employed in a diverse range of sectors, including

- Water and Wastewater Treatment They are commonly used in both municipal and industrial water treatment facilities for pumping water, chemicals, and effluents. - Mining and Mineral Processing In mining, these pumps transport slurries and other abrasive media, making them integral to mineral processing.

- Chemical and Petrochemical Industries Vertical centrifugal pumps handle corrosive liquids and are crucial in chemical processing and transportation.

- Firefighting Systems Their robust design allows them to deliver high-pressure water streams for fire protection.

- Irrigation Farmers and agricultural businesses utilize these pumps for effective irrigation, ensuring water is distributed across large areas.

In conclusion, vertical centrifugal pumps are a vital component in modern fluid handling systems. With their space-saving design, versatility, and efficient operation, they are indispensable across various industries, from water treatment to chemical processing. As technology continues to advance, these pumps will likely evolve further, enhancing their efficiency and broadening their application scope.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024