-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 02, 2025 00:55

Back to list

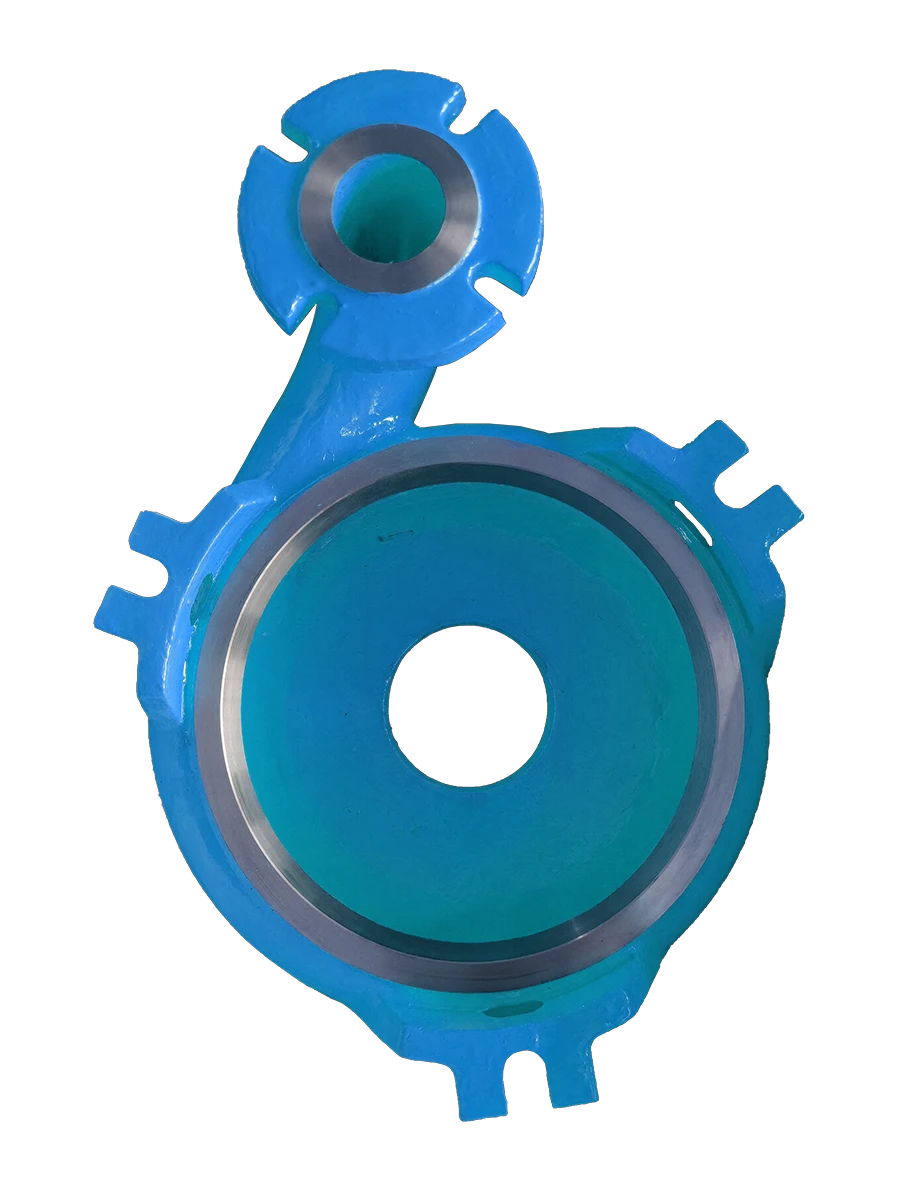

vertical centrifugal casting

Vertical centrifugal casting, a crucial technique within the metallurgical and manufacturing industries, not only stands as a testament to the advancement of industrial technology but also illuminates the path toward the future of precise metal casting. This highly specialized method, distinct in its approach and execution, merges efficiency with quality, proving indispensable in today’s production landscapes.

The authority of vertical centrifugal casting is solidified through a plethora of industry endorsements and the embracing of this method by noted metallurgical institutions and research bodies. Published studies underscore its superiority in specific applications, highlighting its prominence as a preferred technique where conventional methods fail to achieve desired results. For instance, the production of high-fidelity engine components where performance under extreme thermal conditions is non-negotiable, vertical casting stands as a reliable ally. Trust, the cornerstone of any industrial endeavor, is inherently woven into the fabric of vertical centrifugal casting. Its adherence to precision, coupled with a proven track record, positions it as a trusted partner in product manufacturing. Quality control processes involved are rigorous, often involving non-destructive testing methods such as ultrasonic testing or radiography to ensure the fidelity of the cast components. Manufacturers committed to delivering products that inspire confidence in end-users recognize the invaluable assurance provided by this meticulous process. In summary, vertical centrifugal casting is not merely a method of production; it is an innovative blend of tradition and technology, refined by years of industry evolution. Its commitment to precision, expert execution, and unwavering trustworthiness makes it indispensable for industries where excellence is non-negotiable. As industries continue to evolve, the inherent advantages of vertical centrifugal casting make it a pillar of modern manufacturing, providing a foundation upon which future advancements can be confidently built.

The authority of vertical centrifugal casting is solidified through a plethora of industry endorsements and the embracing of this method by noted metallurgical institutions and research bodies. Published studies underscore its superiority in specific applications, highlighting its prominence as a preferred technique where conventional methods fail to achieve desired results. For instance, the production of high-fidelity engine components where performance under extreme thermal conditions is non-negotiable, vertical casting stands as a reliable ally. Trust, the cornerstone of any industrial endeavor, is inherently woven into the fabric of vertical centrifugal casting. Its adherence to precision, coupled with a proven track record, positions it as a trusted partner in product manufacturing. Quality control processes involved are rigorous, often involving non-destructive testing methods such as ultrasonic testing or radiography to ensure the fidelity of the cast components. Manufacturers committed to delivering products that inspire confidence in end-users recognize the invaluable assurance provided by this meticulous process. In summary, vertical centrifugal casting is not merely a method of production; it is an innovative blend of tradition and technology, refined by years of industry evolution. Its commitment to precision, expert execution, and unwavering trustworthiness makes it indispensable for industries where excellence is non-negotiable. As industries continue to evolve, the inherent advantages of vertical centrifugal casting make it a pillar of modern manufacturing, providing a foundation upon which future advancements can be confidently built.

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024