-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 23:40

Back to list

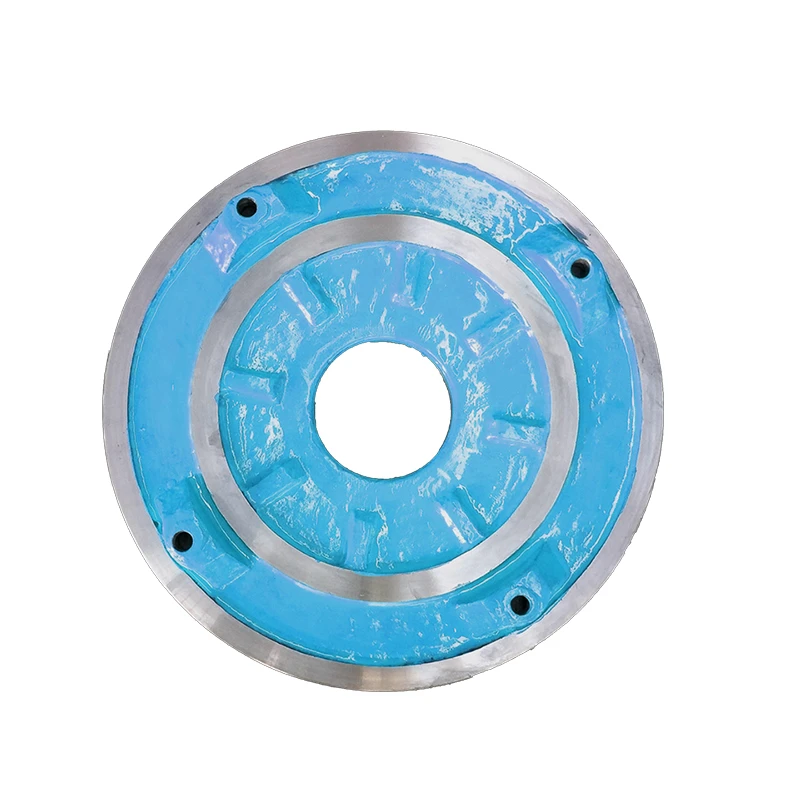

use of impeller

In the realm of industrial machinery and fluid dynamics, the role of impellers stands paramount. They're the unsung heroes of many systems, gracefully converting rotational energy into fluid movement, thereby powering industries ranging from water treatment to aviation. The use of impellers is often underestimated, yet they are quintessential in optimizing efficiency and performance in applications where fluid propulsion is key.

When discussing authoritativeness in the application of impellers, it is essential to highlight the precision engineering and technological advances that have refined their design over years. Computational fluid dynamics (CFD) simulations play a significant role in the development of impellers, allowing for the optimization of blade angles, thickness, and curvature to maximize efficiency and minimize energy consumption. This iterative process of design and testing underpins the authority of manufacturers who continuously push the envelope in impeller technology. Trustworthiness in the use of impellers, especially in critical industrial applications, is bolstered by stringent quality control measures and adherence to international standards such as ISO 1940 for balancing and ISO 5199 for chemical process pumps. Regular maintenance and performance checks are crucial for ensuring reliability. This trust is further cemented when manufacturers offer comprehensive service agreements and support for maintenance, ensuring minimal downtime and maximal operational efficiency. In conclusion, the use of impellers is a sophisticated blend of science and art, where the right choice can lead to significant improvements in system performance and energy efficiency. Their application is far-reaching, impacting various industries globally. Whether used in municipal water systems, chemical manufacturing, or aerospace, the impeller's role cannot be overstated. As industries continue to evolve, impellers will remain at the forefront, driving innovation and efficiency in the world of fluid dynamics.

When discussing authoritativeness in the application of impellers, it is essential to highlight the precision engineering and technological advances that have refined their design over years. Computational fluid dynamics (CFD) simulations play a significant role in the development of impellers, allowing for the optimization of blade angles, thickness, and curvature to maximize efficiency and minimize energy consumption. This iterative process of design and testing underpins the authority of manufacturers who continuously push the envelope in impeller technology. Trustworthiness in the use of impellers, especially in critical industrial applications, is bolstered by stringent quality control measures and adherence to international standards such as ISO 1940 for balancing and ISO 5199 for chemical process pumps. Regular maintenance and performance checks are crucial for ensuring reliability. This trust is further cemented when manufacturers offer comprehensive service agreements and support for maintenance, ensuring minimal downtime and maximal operational efficiency. In conclusion, the use of impellers is a sophisticated blend of science and art, where the right choice can lead to significant improvements in system performance and energy efficiency. Their application is far-reaching, impacting various industries globally. Whether used in municipal water systems, chemical manufacturing, or aerospace, the impeller's role cannot be overstated. As industries continue to evolve, impellers will remain at the forefront, driving innovation and efficiency in the world of fluid dynamics.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024