-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 06:47

Back to list

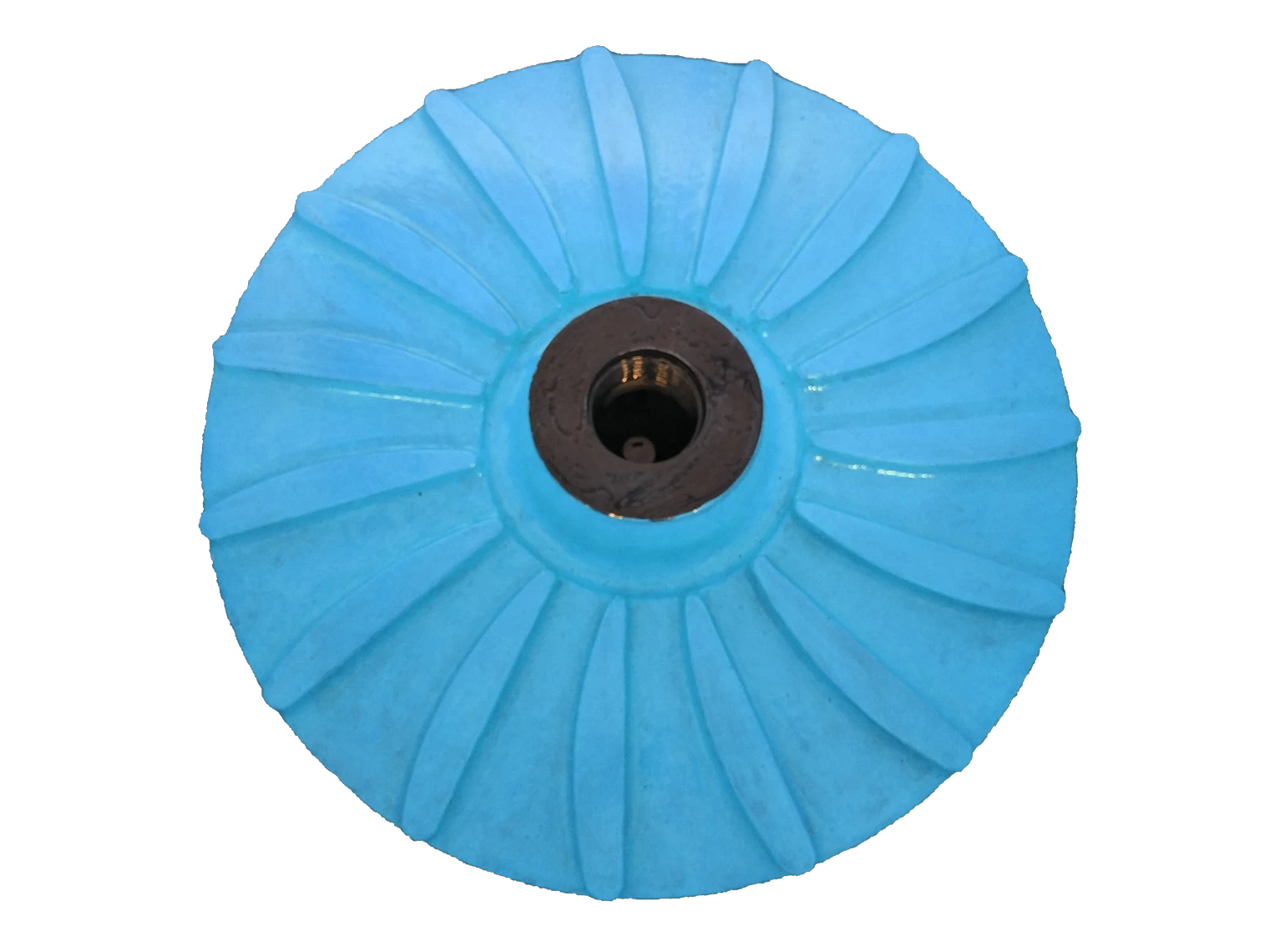

types of impeller in centrifugal pump

Centrifugal pumps are integral to modern industry, serving as essential components in sectors ranging from water treatment to chemical processing. At the heart of these pumps lies the impeller, a rotating device responsible for transferring energy from the motor to the fluid, thus providing the momentum needed for flow. Understanding the different types of impellers is crucial for optimizing pump performance and efficiency, ensuring that the right type is used for the specific application. Each type of impeller offers distinct advantages determined by design and operating conditions.

Vortex impellers, also known as recessed impellers, are specialized designs perfect for handling fluids with large, fibrous, or gaseous particles. Positioned away from the fluid stream, the impeller creates a vortex, effectively reducing the contact between the solids and the impeller itself. This unique feature significantly reduces wear and tear while virtually eliminating clogging, making vortex impellers ideal for sewage and industrial waste applications. Multi-Stage Impellers For applications requiring high heads, multi-stage impellers offer a fitting solution. These impellers work in series within the same pump casing, each offering an additional boost to the fluid's pressure. This configuration is ideal for applications involving significant elevation changes or requiring substantial pressure increase, such as in high-rise buildings or extensive fluid transportation pipelines. Choosing the Right Impeller Selecting the appropriate impeller type involves a blend of understanding the fluid's properties, the operational environment, and the specific performance requirements. For professionals in the industry, the impeller is not just a component; it is a critical factor in achieving efficiency, reducing maintenance costs, and ensuring reliable operation. Impeller selection must consider factors such as the fluid's viscosity, potential for solids, and required pump head and flow rate. Consulting with experts or utilizing pump selection software can lead to informed decisions, directly impacting the plant's overall productivity. Advancements in materials and design technologies continually expand impeller applications, driving efficiency and broadening their utility across industries. Whether handling clean water, chemical solutions, or abrasive slurries, the right impeller choice can greatly influence operational success. Combining this understanding with regular maintenance and monitoring can yield extended equipment life and optimized performance, fulfilling both economic and environmental sustainability goals. Each impeller type has been refined through decades of engineering expertise and practical experience, underscoring the importance of informed selection in improving system reliability and efficiency.

Vortex impellers, also known as recessed impellers, are specialized designs perfect for handling fluids with large, fibrous, or gaseous particles. Positioned away from the fluid stream, the impeller creates a vortex, effectively reducing the contact between the solids and the impeller itself. This unique feature significantly reduces wear and tear while virtually eliminating clogging, making vortex impellers ideal for sewage and industrial waste applications. Multi-Stage Impellers For applications requiring high heads, multi-stage impellers offer a fitting solution. These impellers work in series within the same pump casing, each offering an additional boost to the fluid's pressure. This configuration is ideal for applications involving significant elevation changes or requiring substantial pressure increase, such as in high-rise buildings or extensive fluid transportation pipelines. Choosing the Right Impeller Selecting the appropriate impeller type involves a blend of understanding the fluid's properties, the operational environment, and the specific performance requirements. For professionals in the industry, the impeller is not just a component; it is a critical factor in achieving efficiency, reducing maintenance costs, and ensuring reliable operation. Impeller selection must consider factors such as the fluid's viscosity, potential for solids, and required pump head and flow rate. Consulting with experts or utilizing pump selection software can lead to informed decisions, directly impacting the plant's overall productivity. Advancements in materials and design technologies continually expand impeller applications, driving efficiency and broadening their utility across industries. Whether handling clean water, chemical solutions, or abrasive slurries, the right impeller choice can greatly influence operational success. Combining this understanding with regular maintenance and monitoring can yield extended equipment life and optimized performance, fulfilling both economic and environmental sustainability goals. Each impeller type has been refined through decades of engineering expertise and practical experience, underscoring the importance of informed selection in improving system reliability and efficiency.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024