-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 10:19

Back to list

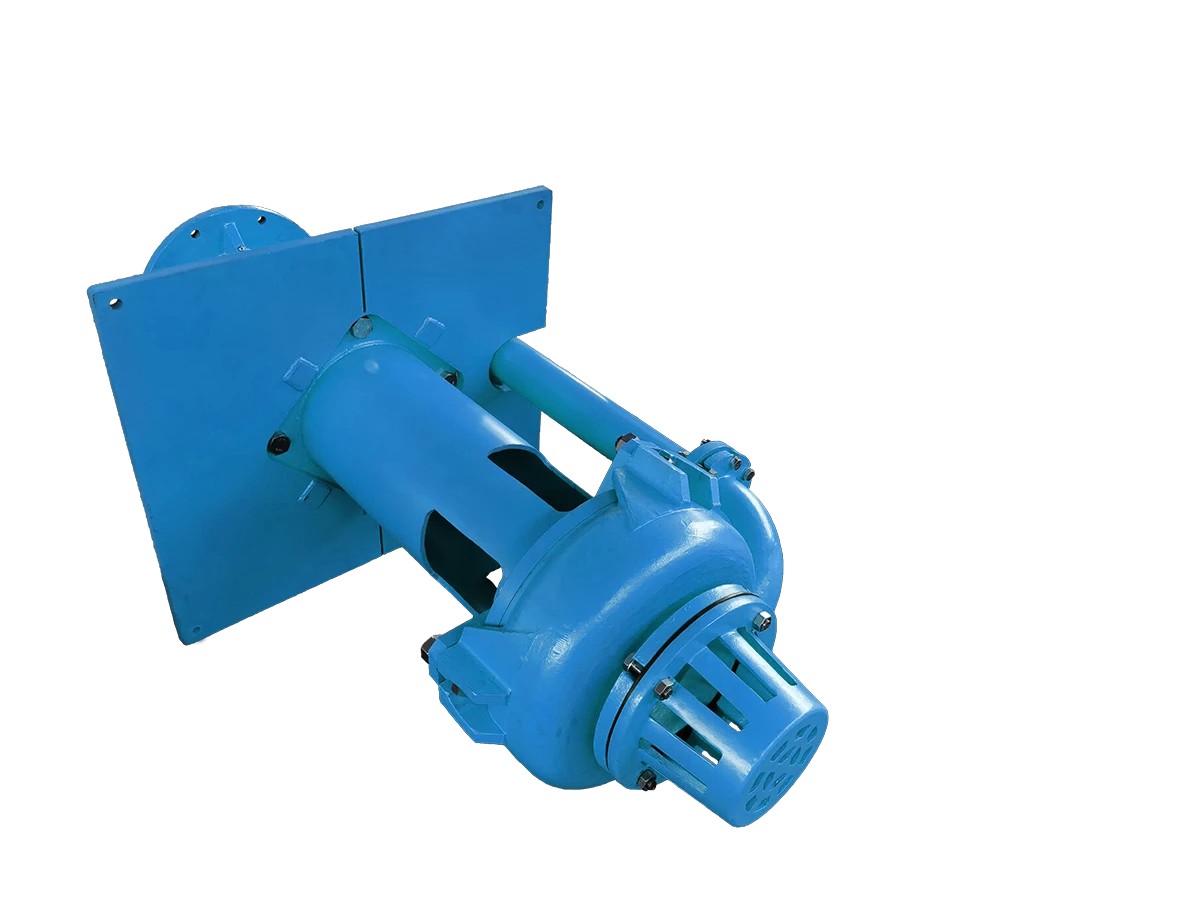

types of bearing used in pumps

In the realm of mechanical engineering, pumps stand as pivotal components across various industries. A critical aspect of pump functionality and durability lies in the bearings that support and facilitate their operation. This article delves into the diverse types of bearings employed in pumps, highlighting their distinctive features, applications, and the expertise required for their optimal use.

Journal Bearings Known for their high load capacity and reliability in harsh conditions, journal bearings are frequently found in large-scale, industrial pumps. These bearings require a lubrication film, which fundamentally decreases friction and wear. Proper expertise in lubrication systems and regular monitoring is crucial to maximize their efficiency and longevity. Composite Bearings With a growing demand for materials that resist corrosion and reduce maintenance costs, composite bearings are gaining traction. Typically used in water and slurry pumps exposed to abrasive environments, these bearings combine high wear resistance with self-lubricating properties. Engineers must possess specialized knowledge in material sciences to select the appropriate composites, ensuring compatibility with the fluid properties and operational conditions. Understanding the intricacies of each bearing type is vital for professionals in pump design and maintenance. The selection process is not merely about identifying a suitable bearing but also involves anticipating operational challenges and designing system components accordingly. Mastery of these concepts underscores the importance of continuous learning and adaptation in the engineering field, dictating not only the performance but also the sustainability of pump systems. Ultimately, the integration of the right bearings determines the functionality and efficiency of pumps across various sectors. Expertise, grounded in comprehensive knowledge and practical experience, is paramount in navigating the complexities of bearing technology. As industry advancements continue to unfold, staying informed and adapting to new innovations will ensure that pump systems achieve their highest potential, reinforcing trust in their enduring reliability and performance.

Journal Bearings Known for their high load capacity and reliability in harsh conditions, journal bearings are frequently found in large-scale, industrial pumps. These bearings require a lubrication film, which fundamentally decreases friction and wear. Proper expertise in lubrication systems and regular monitoring is crucial to maximize their efficiency and longevity. Composite Bearings With a growing demand for materials that resist corrosion and reduce maintenance costs, composite bearings are gaining traction. Typically used in water and slurry pumps exposed to abrasive environments, these bearings combine high wear resistance with self-lubricating properties. Engineers must possess specialized knowledge in material sciences to select the appropriate composites, ensuring compatibility with the fluid properties and operational conditions. Understanding the intricacies of each bearing type is vital for professionals in pump design and maintenance. The selection process is not merely about identifying a suitable bearing but also involves anticipating operational challenges and designing system components accordingly. Mastery of these concepts underscores the importance of continuous learning and adaptation in the engineering field, dictating not only the performance but also the sustainability of pump systems. Ultimately, the integration of the right bearings determines the functionality and efficiency of pumps across various sectors. Expertise, grounded in comprehensive knowledge and practical experience, is paramount in navigating the complexities of bearing technology. As industry advancements continue to unfold, staying informed and adapting to new innovations will ensure that pump systems achieve their highest potential, reinforcing trust in their enduring reliability and performance.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024