-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 17:45

Back to list

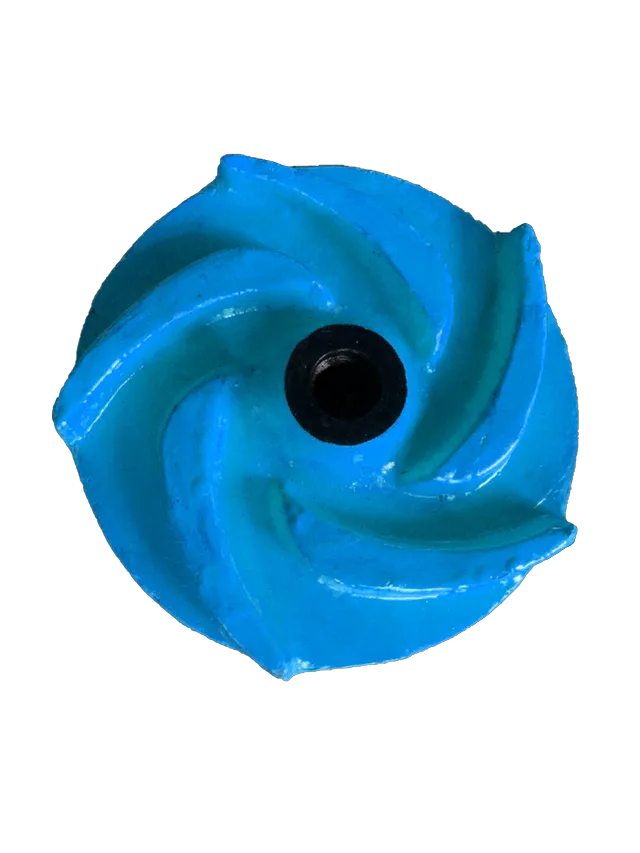

twin impeller pump

Twin impeller pumps, known for their efficiency and versatility, have revolutionized fluid management across various industries. These pumps, featuring two impellers, offer distinct advantages over traditional single impeller designs, providing enhanced performance and reliability.

In applications where precision is critical, such as in the pharmaceutical or food processing industries, twin impeller pumps provide unmatched control over fluid handling. Their ability to deliver a steady output with minimal pulsations ensures that delicate processes remain uncompromised, maintaining product integrity from start to finish. Professionals across the globe endorse twin impeller pumps not only for their technical expertise but also for their adaptability to challenging environments. Their capacity to withstand varying temperatures and pressures makes them an authoritative solution in regions with harsh climatic conditions or in industries subjected to extreme operational demands. While selecting a twin impeller pump, it is crucial to consider factors such as the specific application's flow rate, pressure requirements, and fluid characteristics. Consulting with experts or manufacturers can provide valuable insights, ensuring that the chosen pump aligns with operational needs and long-term goals. Ultimately, the reliability and efficiency of twin impeller pumps make them a cornerstone in fluid management systems. By integrating these pumps into their systems, industries can achieve substantial improvements in productivity and sustainability. Their contribution to energy-saving measures and reduced environmental impact further underscores their position as a preferred choice in modern industrial applications. In conclusion, the twin impeller pump stands as a testament to engineering innovation, combining efficiency, durability, and precision. As industries evolve, the demand for such reliable and efficient fluid management solutions is only set to increase, affirming the pump's role as a critical component in the pursuit of operational excellence.

In applications where precision is critical, such as in the pharmaceutical or food processing industries, twin impeller pumps provide unmatched control over fluid handling. Their ability to deliver a steady output with minimal pulsations ensures that delicate processes remain uncompromised, maintaining product integrity from start to finish. Professionals across the globe endorse twin impeller pumps not only for their technical expertise but also for their adaptability to challenging environments. Their capacity to withstand varying temperatures and pressures makes them an authoritative solution in regions with harsh climatic conditions or in industries subjected to extreme operational demands. While selecting a twin impeller pump, it is crucial to consider factors such as the specific application's flow rate, pressure requirements, and fluid characteristics. Consulting with experts or manufacturers can provide valuable insights, ensuring that the chosen pump aligns with operational needs and long-term goals. Ultimately, the reliability and efficiency of twin impeller pumps make them a cornerstone in fluid management systems. By integrating these pumps into their systems, industries can achieve substantial improvements in productivity and sustainability. Their contribution to energy-saving measures and reduced environmental impact further underscores their position as a preferred choice in modern industrial applications. In conclusion, the twin impeller pump stands as a testament to engineering innovation, combining efficiency, durability, and precision. As industries evolve, the demand for such reliable and efficient fluid management solutions is only set to increase, affirming the pump's role as a critical component in the pursuit of operational excellence.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024