-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 05, 2025 06:07

Back to list

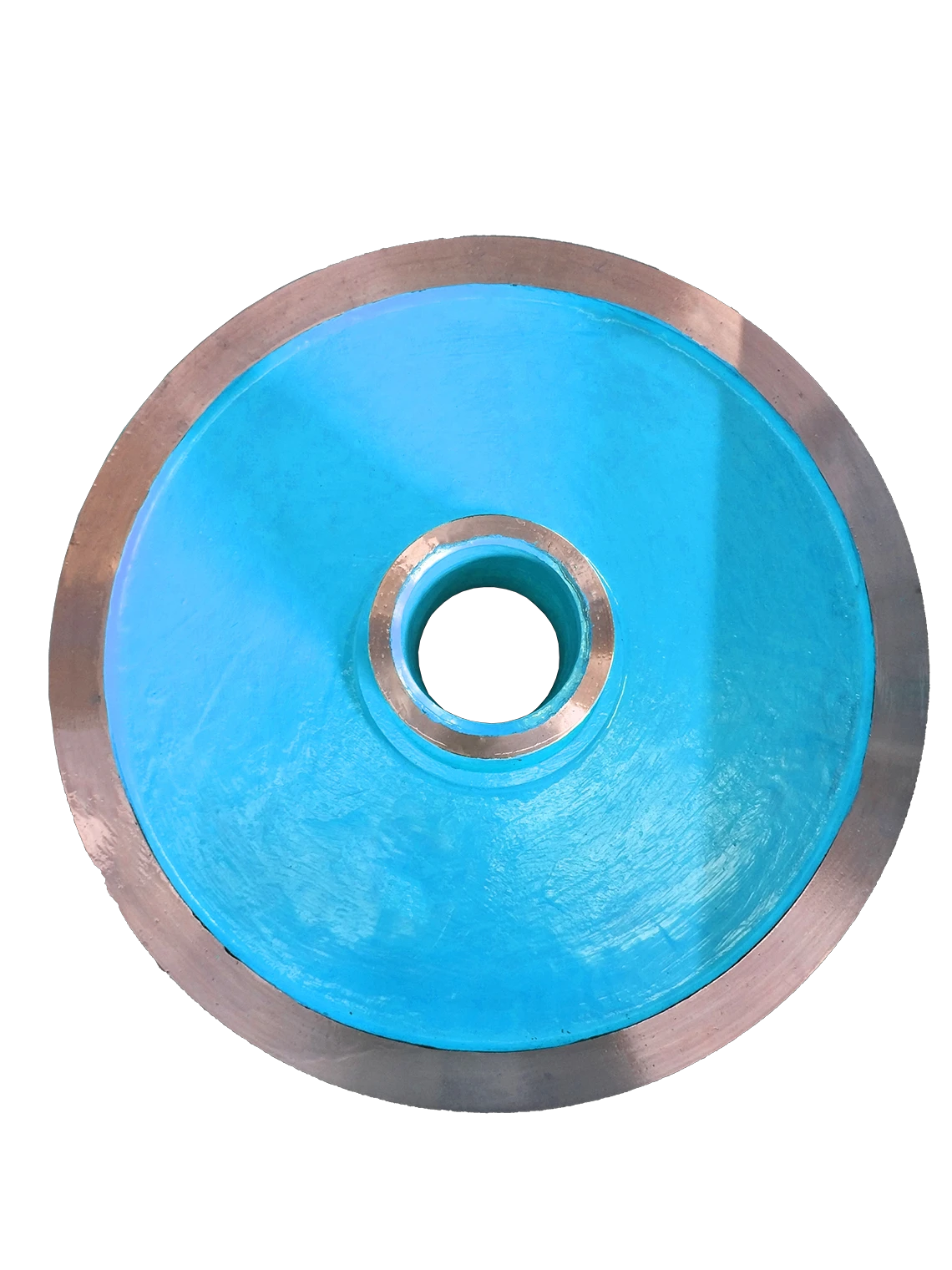

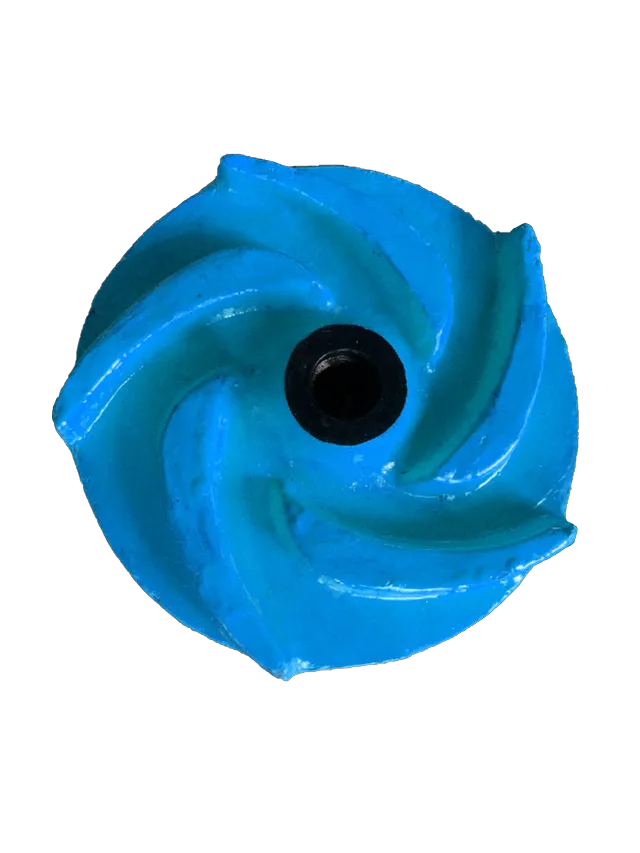

Pump Wear Parts SP65092 Metal

Selecting the right sump slurry pump is paramount for industries dealing with thick, abrasive, and potentially corrosive materials. A sump slurry pump serves as the backbone of operations such as mining, mineral processing, and large-scale industrial waste management, where removing slurry efficiently and reliably is essential.

Trust in sump slurry pump performance is built through certifications and adherence to industry standards. Reputable manufacturers offer products that comply with internationally recognized standards such as the ISO 9001 for quality management and ISO 14001 for environmental management. These certifications not only assure product quality but also underscore a commitment to sustainable and efficient industrial practices. When discussing new developments, contemporary advancements in pump technology have introduced smart pumps with advanced IoT capabilities. These pumps provide predictive maintenance alerts and remote performance monitoring, which preemptively addresses issues before they escalate. A case study from a chemical processing plant illustrated how implementing IoT-enabled sump slurry pumps reduced their unscheduled maintenance incidents by 40%, demonstrating tangible improvements in operational trustworthiness and reliability. In conclusion, the decision to invest in a quality sump slurry pump hinges upon a combination of expert recommendations, material quality, engineering design, and integration of advanced technological features. With comprehensive planning and adherence to best practices outlined by industry leaders, businesses can achieve significant cost savings, improve operational reliability, and ensure long-lasting performance from their sump slurry pumps.

Trust in sump slurry pump performance is built through certifications and adherence to industry standards. Reputable manufacturers offer products that comply with internationally recognized standards such as the ISO 9001 for quality management and ISO 14001 for environmental management. These certifications not only assure product quality but also underscore a commitment to sustainable and efficient industrial practices. When discussing new developments, contemporary advancements in pump technology have introduced smart pumps with advanced IoT capabilities. These pumps provide predictive maintenance alerts and remote performance monitoring, which preemptively addresses issues before they escalate. A case study from a chemical processing plant illustrated how implementing IoT-enabled sump slurry pumps reduced their unscheduled maintenance incidents by 40%, demonstrating tangible improvements in operational trustworthiness and reliability. In conclusion, the decision to invest in a quality sump slurry pump hinges upon a combination of expert recommendations, material quality, engineering design, and integration of advanced technological features. With comprehensive planning and adherence to best practices outlined by industry leaders, businesses can achieve significant cost savings, improve operational reliability, and ensure long-lasting performance from their sump slurry pumps.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024