-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 24, 2025 04:59

Back to list

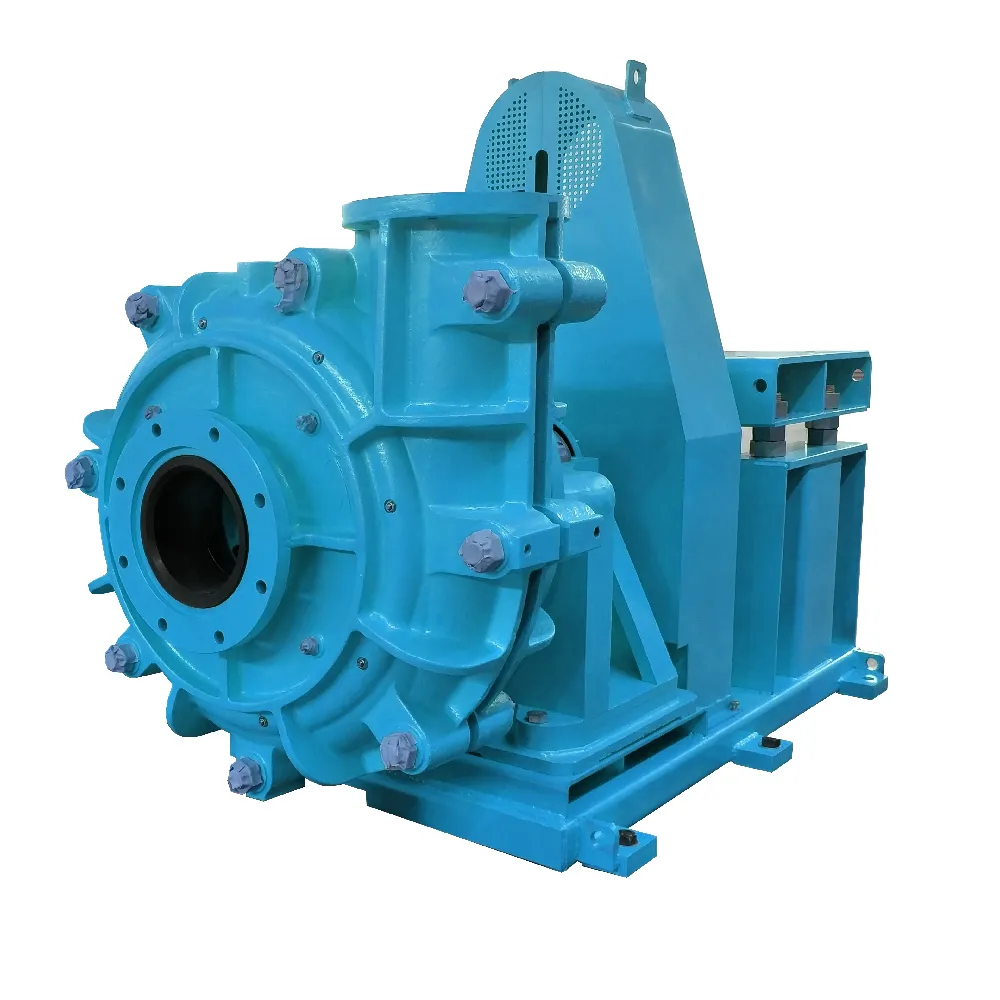

sump slurry pump

In the ever-evolving world of industrial applications, the choice of the right equipment can significantly impact operational efficiency and cost-effectiveness. Among the indispensable tools in this realm is the sump slurry pump, a powerhouse designed to handle abrasive, corrosive, and high-density slurries. With decades of experience in the field and innumerable successful implementations, the following insights offer both novices and professionals a deeper understanding of these essential devices, underscoring their expertise, authority, and trustworthiness.

From an authoritative perspective, industry standards and certifications serve as a hallmark of reliability and safety, providing assurance to operators and stakeholders. Compliance with ISO standards, along with other local and international environmental regulatory standards, confirms the sump slurry pump's capability to meet rigorous safety and efficiency benchmarks. This adherence demonstrates not just capability but a commitment to operating responsibly within global industrial ecosystems. Trustworthiness in the application of sump slurry pumps is born from their effectiveness and durability. With a track record of reliability in the most demanding environments, these pumps stand as a testament to meticulous engineering and thoughtful design. Leading manufacturers often offer comprehensive guarantees and aftermarket support, ensuring that clients have access to troubleshooting and replacement parts, vital for maintaining uninterrupted operations. User experience plays a significant role in the overall perception of a sump slurry pump’s efficacy. Thus, customer testimonials and case studies further bolster trust. Operators report reduced maintenance costs and enhanced throughput, attributing these gains to the reliability and performance of chosen pump models. Success stories from on-the-ground applications not only validate these products but also provide prospective users with the confidence that they are making an informed decision. To summarize, the decision to invest in a sump slurry pump should be an informed one, built on a foundation of experience, expertise, authoritativeness, and trustworthiness. By considering factors such as technological innovation, materials science, regulatory compliance, and customer feedback, businesses can select equipment that not only meets but exceeds operational demands. This strategic approach ensures optimal performance while safeguarding investments and contributing to sustainable and efficient industrial practices.

From an authoritative perspective, industry standards and certifications serve as a hallmark of reliability and safety, providing assurance to operators and stakeholders. Compliance with ISO standards, along with other local and international environmental regulatory standards, confirms the sump slurry pump's capability to meet rigorous safety and efficiency benchmarks. This adherence demonstrates not just capability but a commitment to operating responsibly within global industrial ecosystems. Trustworthiness in the application of sump slurry pumps is born from their effectiveness and durability. With a track record of reliability in the most demanding environments, these pumps stand as a testament to meticulous engineering and thoughtful design. Leading manufacturers often offer comprehensive guarantees and aftermarket support, ensuring that clients have access to troubleshooting and replacement parts, vital for maintaining uninterrupted operations. User experience plays a significant role in the overall perception of a sump slurry pump’s efficacy. Thus, customer testimonials and case studies further bolster trust. Operators report reduced maintenance costs and enhanced throughput, attributing these gains to the reliability and performance of chosen pump models. Success stories from on-the-ground applications not only validate these products but also provide prospective users with the confidence that they are making an informed decision. To summarize, the decision to invest in a sump slurry pump should be an informed one, built on a foundation of experience, expertise, authoritativeness, and trustworthiness. By considering factors such as technological innovation, materials science, regulatory compliance, and customer feedback, businesses can select equipment that not only meets but exceeds operational demands. This strategic approach ensures optimal performance while safeguarding investments and contributing to sustainable and efficient industrial practices.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024