-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 13:20

Back to list

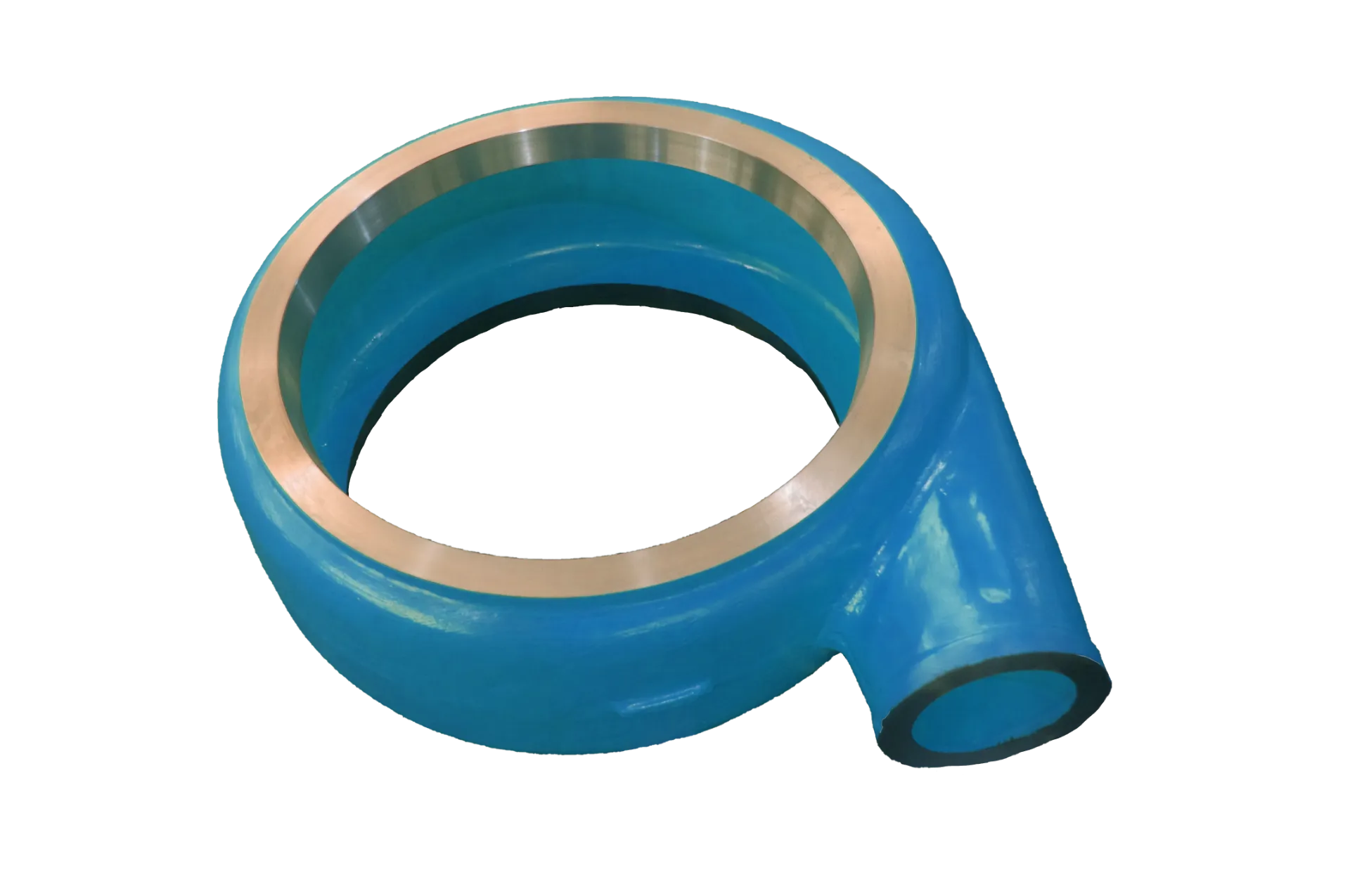

suction casing

Suction casing is a critical element in various industrial applications, serving as a key component in pumps, particularly centrifugal pumps. These casings are designed to efficiently manage the flow of fluid into the pump, ensuring optimal performance and durability. Mastery of the intricacies of suction casings not only enhances product performance but also guarantees reliability over prolonged periods.

Trustworthiness in suction casings is established through exhaustive testing and real-world application results. Documenting case studies and reliability tests provides end users with confidence in product claims. For instance, a reputable manufacturer might present empirical data showcasing the performance longevity under specific operational scenarios, thereby substantiating their product’s quality. One current trend in suction casing innovation is sustainability. With growing environmental concerns, manufacturers are exploring eco-friendly materials and production methods that reduce carbon footprints without compromising on performance. This sustainable approach not only aligns with global environmental goals but also appeals to a conscientious consumer base seeking to implement greener technologies. Moreover, the maintenance aspect plays a crucial role in establishing trust. Products designed with ease of maintenance in mind—including easy dismantling and assembly—demonstrate thoughtful engineering that respects the user’s time and resources. Offering comprehensive documentation and support further elevates the product's reliability, offering peace of mind and ensuring seamless operation across its lifecycle. In conclusion, the suction casing is not merely a structural component, but a sophisticated piece of engineering pivotal to pump efficacy. Its design, material selection, and adherence to standards are fundamental elements that establish a product’s experience, expertise, authoritativeness, and trustworthiness. With advances in technology and a focus on sustainability, the future of suction casing looks poised to meet and exceed evolving industrial demands, offering an optimal solution that benefits both manufacturers and end-users alike.

Trustworthiness in suction casings is established through exhaustive testing and real-world application results. Documenting case studies and reliability tests provides end users with confidence in product claims. For instance, a reputable manufacturer might present empirical data showcasing the performance longevity under specific operational scenarios, thereby substantiating their product’s quality. One current trend in suction casing innovation is sustainability. With growing environmental concerns, manufacturers are exploring eco-friendly materials and production methods that reduce carbon footprints without compromising on performance. This sustainable approach not only aligns with global environmental goals but also appeals to a conscientious consumer base seeking to implement greener technologies. Moreover, the maintenance aspect plays a crucial role in establishing trust. Products designed with ease of maintenance in mind—including easy dismantling and assembly—demonstrate thoughtful engineering that respects the user’s time and resources. Offering comprehensive documentation and support further elevates the product's reliability, offering peace of mind and ensuring seamless operation across its lifecycle. In conclusion, the suction casing is not merely a structural component, but a sophisticated piece of engineering pivotal to pump efficacy. Its design, material selection, and adherence to standards are fundamental elements that establish a product’s experience, expertise, authoritativeness, and trustworthiness. With advances in technology and a focus on sustainability, the future of suction casing looks poised to meet and exceed evolving industrial demands, offering an optimal solution that benefits both manufacturers and end-users alike.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024