-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

submersible slurry pump price

Understanding Submersible Slurry Pump Prices Factors Influencing Costs

Submersible slurry pumps are crucial equipment in various industries, particularly in construction, mining, and wastewater management. These pumps are designed to move thick, abrasive liquids and slurries, making them indispensable in environments where standard pumps may falter. Given their importance, understanding the pricing of submersible slurry pumps is essential for businesses seeking to invest in this vital technology.

What Is a Submersible Slurry Pump?

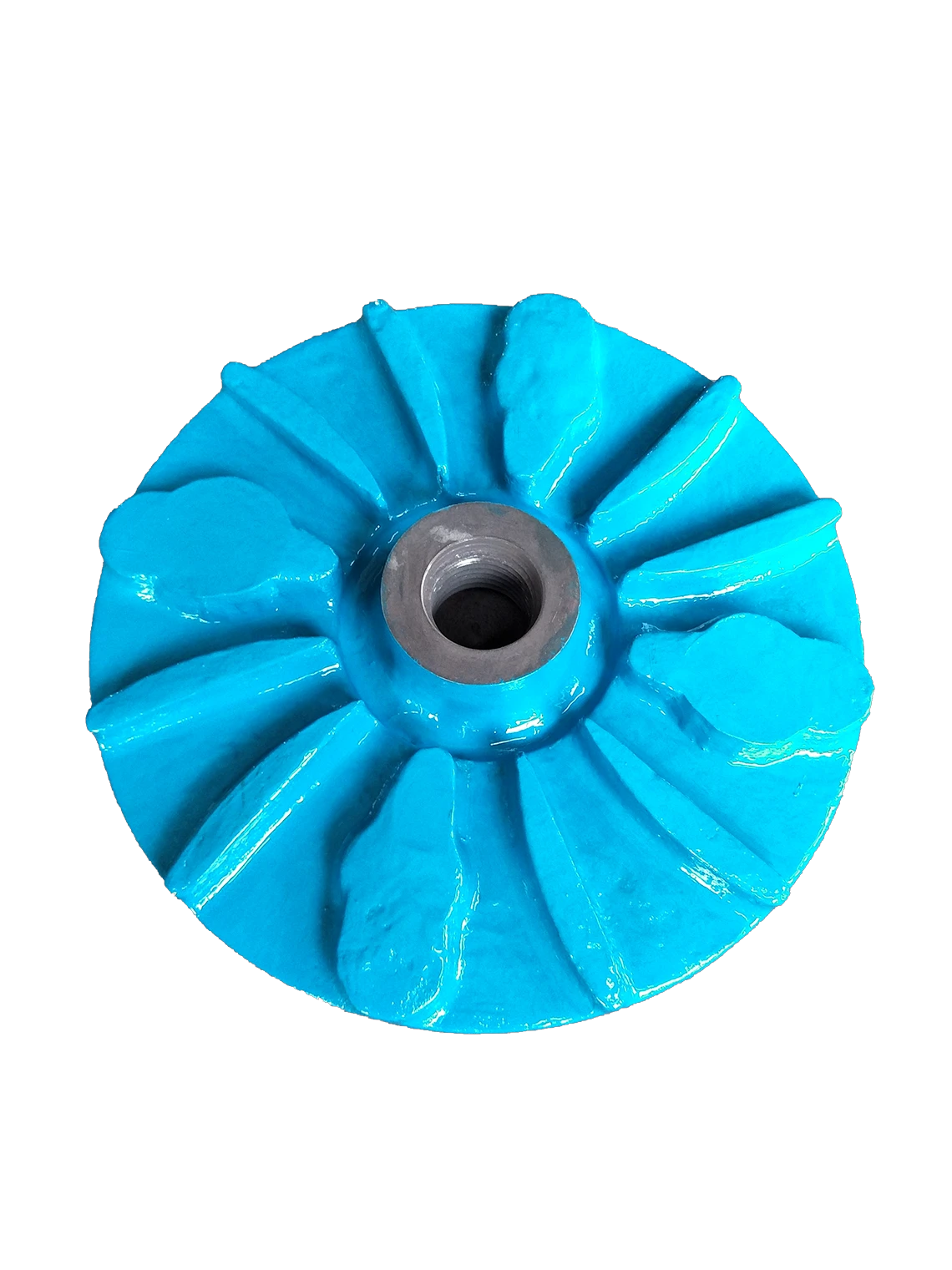

A submersible slurry pump functions by being submerged in the liquid it is pumping. Unlike standard pumps, they are sealed to prevent liquid from entering the motor, ensuring efficient operation even in harsh conditions. The design typically includes a robust impeller and casing that can handle solid particles without getting clogged, making them suitable for transferring slurry mixtures that contain solids, such as mud, sediments, and slurries from drilling operations.

Factors Affecting Prices

1. Material and Construction Quality The materials used in manufacturing submersible slurry pumps significantly impact their cost. High-quality, durable materials like stainless steel or hardened alloys are commonly used for pumps designed to handle abrasive slurries. While these materials increase the upfront cost, they often provide better durability and lower maintenance expenses in the long run.

2. Pump Capacity and Size The capacity of a slurry pump, often measured in gallons per minute (GPM), is a direct correlate to its price. Larger pumps that can handle higher volumes of slurry are typically more expensive. Additionally, the size and weight of the pump can affect shipping and installation costs, further influencing the overall investment.

submersible slurry pump price

3. Type of Slurry Pump There are various types of submersible slurry pumps, including high-head pumps, standard pumps, and specialized pumps for specific applications. Each type has different design specifications and operational capabilities, affecting their pricing structure. Custom pumps designed for unique applications may also come with a higher price tag.

4. Brand Reputation Established brands with a reputation for reliability and quality often command higher prices. However, investing in a reputable brand can yield cost savings over time due to fewer breakdowns and less frequent replacements. Companies should weigh the initial costs against long-term value when selecting a pump brand.

5. Technological Features Modern submersible slurry pumps may incorporate advanced technologies, such as variable frequency drives (VFDs) for improved efficiency and control, automatic monitoring systems, and enhanced filtration systems. While these features can increase the initial purchase price, they might lead to lower operational costs and improved efficiency.

6. Aftermarket Support and Warranty The level of customer support and warranty offered can also influence the price. Comprehensive warranties and robust customer service can provide peace of mind and potentially reduce future costs related to maintenance and repairs.

7. Market Demand and Economic Conditions The overall market demand for construction and mining equipment can vary, impacting the prices of submersible slurry pumps. Economic factors such as inflation, supply chain disruptions, and raw material costs can also play a significant role in determining pump prices.

Conclusion

When considering the purchase of a submersible slurry pump, understanding the various factors that influence price is crucial. While it can be tempting to opt for the lowest-cost option, it is essential to evaluate the pump's quality, features, and potential long-term value. Companies should conduct thorough research, compare different models and brands, and consider total ownership costs before making a final decision. By making informed choices, businesses can ensure they select the right submersible slurry pump to meet their operational needs while maintaining budgetary constraints. In an industry where reliability and efficiency are paramount, investing in a high-quality slurry pump can significantly impact overall productivity and cost-effectiveness.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024