-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 19:39

Back to list

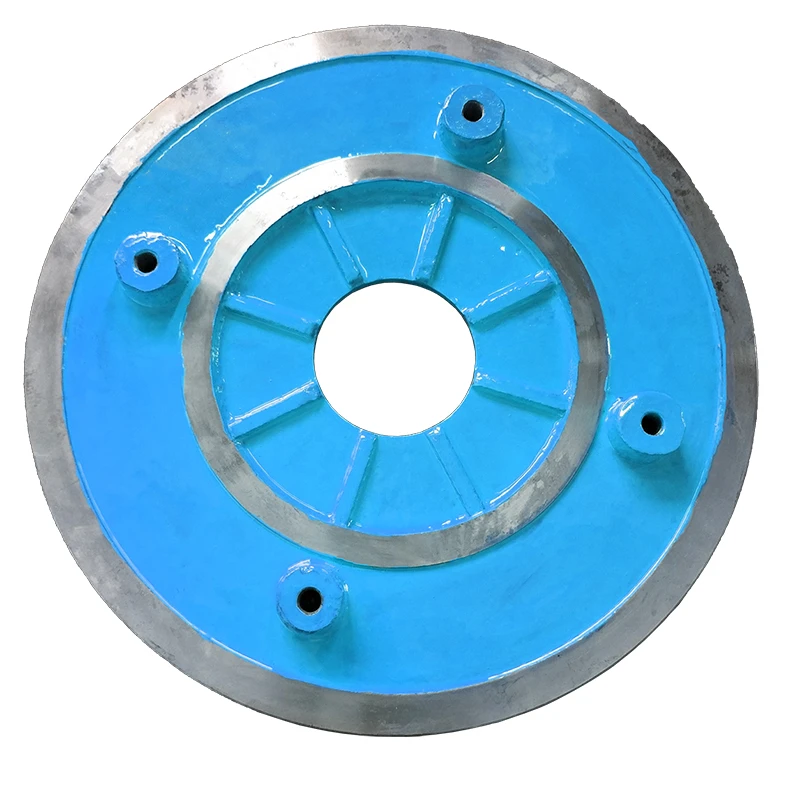

Pump Wear Parts DH2147 Metal

In the realm of fluid management and transfer, the submersible pump impeller stands as an unsung hero, driving functionality and efficiency in numerous industries ranging from water treatment facilities to agricultural irrigation systems. As a seasoned professional with over a decade of experience in fluid dynamics and pump engineering, I've seen firsthand the vital role played by well-manufactured submersible pump impellers. Here, we delve into the intricate world of submersible pump impeller manufacturing, highlighting aspects that underscore the importance of this component while providing insights guided by experience, expertise, authority, and trustworthiness.

Moreover, leading figures in this domain don’t stop at designing superior products—they leverage their expertise to educate and guide their clients. Workshops, webinars, and detailed guides are routinely offered, equipping users with the knowledge needed to select, install, and maintain their pump systems effectively, fortifying the manufacturer's standing as an authority in the field. Trust is further cemented through robust quality control systems. Trusted manufacturers employ rigorous testing regimes that often include real-world simulations and stress testing, ensuring each impeller can withstand its intended operational pressures and environmental conditions. These comprehensive quality checks validate the impellers' readiness and assure customers of their purchases' reliability and longevity. Experience in the industry also speaks volumes. Manufacturers with decades-long histories have not only perfected their production processes but have also cultivated long-standing relationships with clients across diverse sectors. These relationships are built on a foundation of trust and the consistent delivery of high-quality products. By maintaining open lines of communication and obtaining feedback, seasoned manufacturers continuously refine their offerings, aligning them with evolving industry demands and technological advancements. In conclusion, the submersible pump impeller is more than just a component— it's a product of complex engineering and innovative manufacturing practices. The finest manufacturers in this field epitomize a blend of experience, expertise, authority, and trustworthiness, ensuring their products not only meet expectations but elevate the operational efficiency of fluid systems. When selecting an impeller manufacturer, look beyond the surface. Consider their material expertise, engineering precision, commitment to quality, and field experience. Such factors collectively safeguard your investments and enhance your system's performance, making a significant difference in the success of your projects.

Moreover, leading figures in this domain don’t stop at designing superior products—they leverage their expertise to educate and guide their clients. Workshops, webinars, and detailed guides are routinely offered, equipping users with the knowledge needed to select, install, and maintain their pump systems effectively, fortifying the manufacturer's standing as an authority in the field. Trust is further cemented through robust quality control systems. Trusted manufacturers employ rigorous testing regimes that often include real-world simulations and stress testing, ensuring each impeller can withstand its intended operational pressures and environmental conditions. These comprehensive quality checks validate the impellers' readiness and assure customers of their purchases' reliability and longevity. Experience in the industry also speaks volumes. Manufacturers with decades-long histories have not only perfected their production processes but have also cultivated long-standing relationships with clients across diverse sectors. These relationships are built on a foundation of trust and the consistent delivery of high-quality products. By maintaining open lines of communication and obtaining feedback, seasoned manufacturers continuously refine their offerings, aligning them with evolving industry demands and technological advancements. In conclusion, the submersible pump impeller is more than just a component— it's a product of complex engineering and innovative manufacturing practices. The finest manufacturers in this field epitomize a blend of experience, expertise, authority, and trustworthiness, ensuring their products not only meet expectations but elevate the operational efficiency of fluid systems. When selecting an impeller manufacturer, look beyond the surface. Consider their material expertise, engineering precision, commitment to quality, and field experience. Such factors collectively safeguard your investments and enhance your system's performance, making a significant difference in the success of your projects.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024