-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 21, 2025 01:15

Back to list

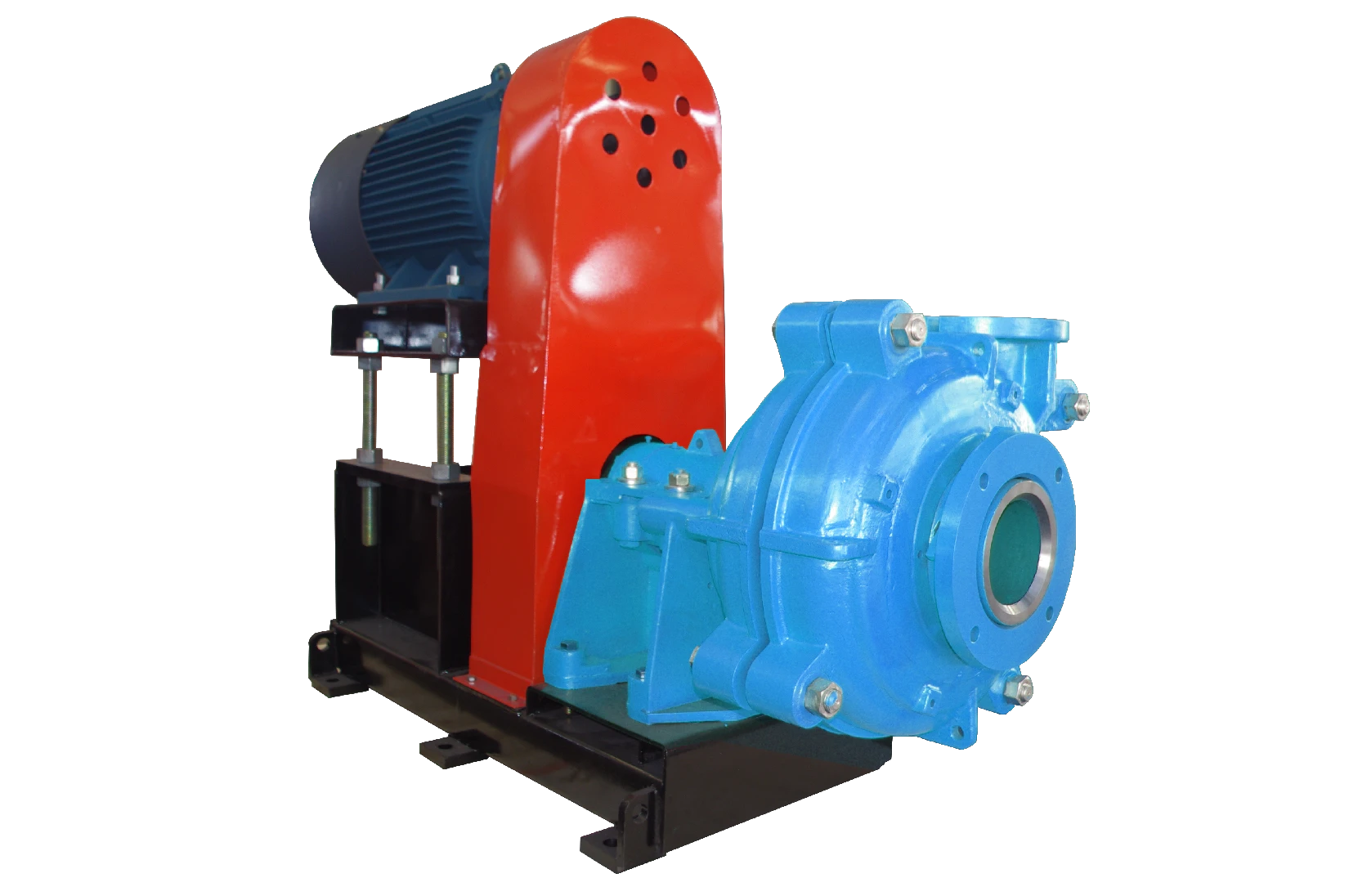

slurry water pump

Navigating the complex landscape of industrial equipment, slurry water pumps stand out as indispensable tools for professionals dealing with challenging materials. Embedded deep within various sectors such as mining, wastewater treatment, and construction, these pumps are engineered to handle the demands of transporting viscous, abrasive, and corrosive fluids. Drawing upon decades of industry experience, it's imperative to understand the nuances of selecting, utilizing, and maintaining these robust machines.

An authoritative voice in the slurry water pump domain is often forged from years of accumulated knowledge and problem-solving. Those seasoned in the field can diagnose subtle anomalies in pump performance that might evade a novice's eye. They draw from a reservoir of case studies where specific issues were resolved through innovative engineering solutions, which contributes to their stature as trusted advisors. Trustworthiness in the slurry pump industry is also built upon transparent communication and documented success rates. Manufacturers and service providers often share testimonials and case studies that highlight their capability in diverse applications. This openness not only strengthens customer confidence but also enhances the perceived reliability of their offerings. Finally, adopting cutting-edge technology is crucial for maintaining industry leadership. Advanced monitoring systems that provide real-time performance data and predictive maintenance alerts are becoming standard features. These innovations minimize the risk of failure and optimize the entire pumping process, thereby enhancing efficiency and reducing operational costs. In conclusion, slurry water pumps are integral to numerous industrial processes, demanding a high level of Experience, Expertise, Authoritativeness, and Trustworthiness from those who manufacture and use them. A comprehensive understanding of their operation, coupled with diligent maintenance and modern technological integrations, ensures these pumps perform to their best potential. This proactive approach guarantees that they remain reliable workhorses in any demanding industrial environment.

An authoritative voice in the slurry water pump domain is often forged from years of accumulated knowledge and problem-solving. Those seasoned in the field can diagnose subtle anomalies in pump performance that might evade a novice's eye. They draw from a reservoir of case studies where specific issues were resolved through innovative engineering solutions, which contributes to their stature as trusted advisors. Trustworthiness in the slurry pump industry is also built upon transparent communication and documented success rates. Manufacturers and service providers often share testimonials and case studies that highlight their capability in diverse applications. This openness not only strengthens customer confidence but also enhances the perceived reliability of their offerings. Finally, adopting cutting-edge technology is crucial for maintaining industry leadership. Advanced monitoring systems that provide real-time performance data and predictive maintenance alerts are becoming standard features. These innovations minimize the risk of failure and optimize the entire pumping process, thereby enhancing efficiency and reducing operational costs. In conclusion, slurry water pumps are integral to numerous industrial processes, demanding a high level of Experience, Expertise, Authoritativeness, and Trustworthiness from those who manufacture and use them. A comprehensive understanding of their operation, coupled with diligent maintenance and modern technological integrations, ensures these pumps perform to their best potential. This proactive approach guarantees that they remain reliable workhorses in any demanding industrial environment.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024