-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 26, 2025 04:24

Back to list

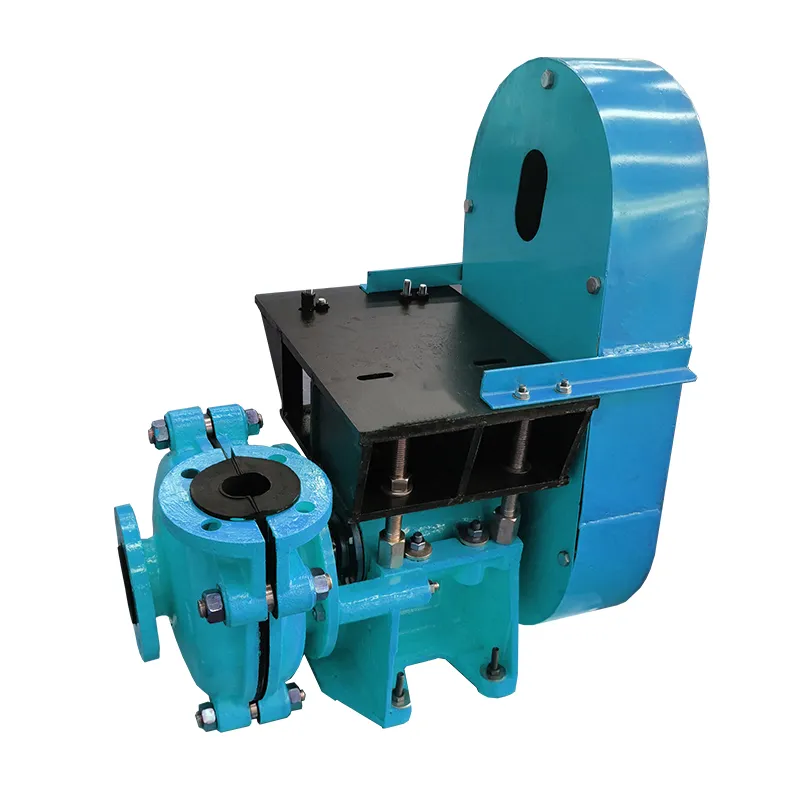

slurry sump pump

In industrial operations, maintaining efficient fluid handling and transport is paramount. A slurry sump pump plays an indispensable role, especially in sectors where the conveyance of abrasive and viscous mixtures is a regular challenge. Delving into its intricacies, this article unravels the core aspects that make slurry sump pumps pivotal, offering insights from decades of industrial know-how, engineering precision, and user trust—the pillars of effective product selection in today's competitive market.

Moreover, authoritativeness in this context is derived from a deep understanding of fluid mechanics and materials science. Manufacturers that engage in rigorous testing and adhere to international standards (like ISO and ANSI) provide assurance of quality and performance. These certifications are not mere endorsements but a testament to a pump's capability to perform reliably across diverse applications worldwide, from mineral processing plants in Australia to wastewater management facilities in the United States. Trustworthiness, perhaps the most intangible yet crucial of all factors, is built over time through consistent performance and customer satisfaction. A noteworthy aspect is the availability of comprehensive after-sales service and technical support. Manufacturers that offer 24/7 customer service, coupled with readily accessible spare parts, ensure that operational disruptions are minimized, reinforcing user confidence in their products. In conclusion, the ideal slurry sump pump is a blend of innovative design and proven resilience, designed to tackle the distinctive challenges posed by slurry transport. Its selection should be guided by a clear understanding of operational demands, material properties, and maintenance requirements. Trust in a reputable manufacturer—one whose expertise, authority, and commitment to quality are unassailable—forms the foundation for operational excellence and sustainable industrial growth. As industries advance, the role of such specialized equipment will only become more integral, championing efficiency and reliability across global landscapes.

Moreover, authoritativeness in this context is derived from a deep understanding of fluid mechanics and materials science. Manufacturers that engage in rigorous testing and adhere to international standards (like ISO and ANSI) provide assurance of quality and performance. These certifications are not mere endorsements but a testament to a pump's capability to perform reliably across diverse applications worldwide, from mineral processing plants in Australia to wastewater management facilities in the United States. Trustworthiness, perhaps the most intangible yet crucial of all factors, is built over time through consistent performance and customer satisfaction. A noteworthy aspect is the availability of comprehensive after-sales service and technical support. Manufacturers that offer 24/7 customer service, coupled with readily accessible spare parts, ensure that operational disruptions are minimized, reinforcing user confidence in their products. In conclusion, the ideal slurry sump pump is a blend of innovative design and proven resilience, designed to tackle the distinctive challenges posed by slurry transport. Its selection should be guided by a clear understanding of operational demands, material properties, and maintenance requirements. Trust in a reputable manufacturer—one whose expertise, authority, and commitment to quality are unassailable—forms the foundation for operational excellence and sustainable industrial growth. As industries advance, the role of such specialized equipment will only become more integral, championing efficiency and reliability across global landscapes.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024