-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 24, 2025 02:41

Back to list

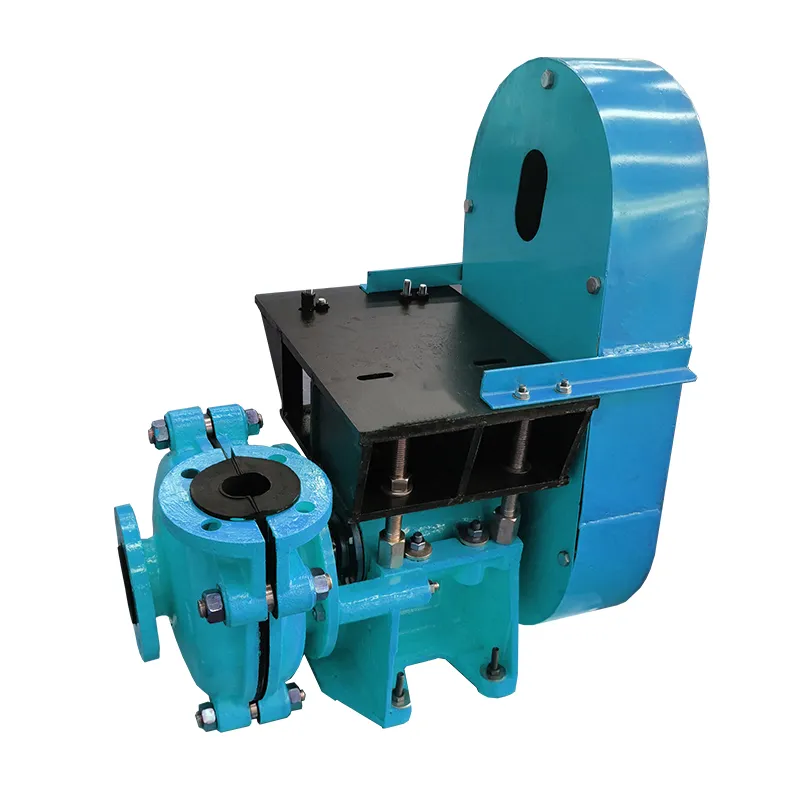

slurry pump with agitator

In the intricate world of industrial applications, the slurry pump with agitator emerges as a vital tool, serving as a linchpin in processes that handle dense and abrasive mixtures. Unlike standard pumps, these sophisticated machines are specifically designed to manage slurries—a critical aspect in sectors such as mining, construction, and wastewater management. The incorporation of an agitator extends their functionality, offering significant advantages that enhance operational efficiency and reduce maintenance needs.

Authoritativeness in the field of slurry pumps is often demonstrated by adhering to industry standards and utilizing proven technologies. Leading manufacturers frequently conduct extensive research and development to innovate and improve the performance of these pumps. They provide case studies and technical papers that highlight successful deployments across diverse industries, establishing their expertise and authority. Engaging with content from these sources enables stakeholders to capitalize on best practices and proven strategies, fostering an informed approach to integrating slurry pumps within their systems. Trustworthiness is a cornerstone of any successful relationship between manufacturers and operators. Reputable companies not only offer robust products but also provide comprehensive support services, including installation guidance, maintenance training, and after-sales support. Moreover, the transparency of product specifications and performance data builds confidence among users, allowing them to select pumps that precisely meet their requirements. Endorsements and testimonials from established industrial players further reinforce the credibility of these machines, offering peace of mind to potential customers. Addressing environmental and safety considerations is another vital aspect enhancing the trustworthiness of slurry pumps with agitators. As industries worldwide face increasing scrutiny regarding their environmental impact, pumps designed with eco-friendliness in mind gain a competitive edge. Efficient slurry management reduces waste and minimizes the risk of environmental contamination. Furthermore, the reliability of these pumps contributes to safer working conditions by diminishing the occurrence of hazardous leaks or equipment failures. In conclusion, a slurry pump with an agitator is an indispensable asset in any operation handling abrasive or dense fluid mixtures. Its design and functionality are tailored to enhance process efficiency, maximize equipment longevity, and meet the rigorous demands of various industrial sectors. By focusing on experience, expertise, authority, and trustworthiness, operators can ensure they select a solution that not only meets their current needs but is also poised to adapt to future challenges. Leveraging these attributes positions organizations for sustained success and operational excellence in an ever-evolving industrial landscape.

Authoritativeness in the field of slurry pumps is often demonstrated by adhering to industry standards and utilizing proven technologies. Leading manufacturers frequently conduct extensive research and development to innovate and improve the performance of these pumps. They provide case studies and technical papers that highlight successful deployments across diverse industries, establishing their expertise and authority. Engaging with content from these sources enables stakeholders to capitalize on best practices and proven strategies, fostering an informed approach to integrating slurry pumps within their systems. Trustworthiness is a cornerstone of any successful relationship between manufacturers and operators. Reputable companies not only offer robust products but also provide comprehensive support services, including installation guidance, maintenance training, and after-sales support. Moreover, the transparency of product specifications and performance data builds confidence among users, allowing them to select pumps that precisely meet their requirements. Endorsements and testimonials from established industrial players further reinforce the credibility of these machines, offering peace of mind to potential customers. Addressing environmental and safety considerations is another vital aspect enhancing the trustworthiness of slurry pumps with agitators. As industries worldwide face increasing scrutiny regarding their environmental impact, pumps designed with eco-friendliness in mind gain a competitive edge. Efficient slurry management reduces waste and minimizes the risk of environmental contamination. Furthermore, the reliability of these pumps contributes to safer working conditions by diminishing the occurrence of hazardous leaks or equipment failures. In conclusion, a slurry pump with an agitator is an indispensable asset in any operation handling abrasive or dense fluid mixtures. Its design and functionality are tailored to enhance process efficiency, maximize equipment longevity, and meet the rigorous demands of various industrial sectors. By focusing on experience, expertise, authority, and trustworthiness, operators can ensure they select a solution that not only meets their current needs but is also poised to adapt to future challenges. Leveraging these attributes positions organizations for sustained success and operational excellence in an ever-evolving industrial landscape.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024