-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 07, 2025 05:30

Back to list

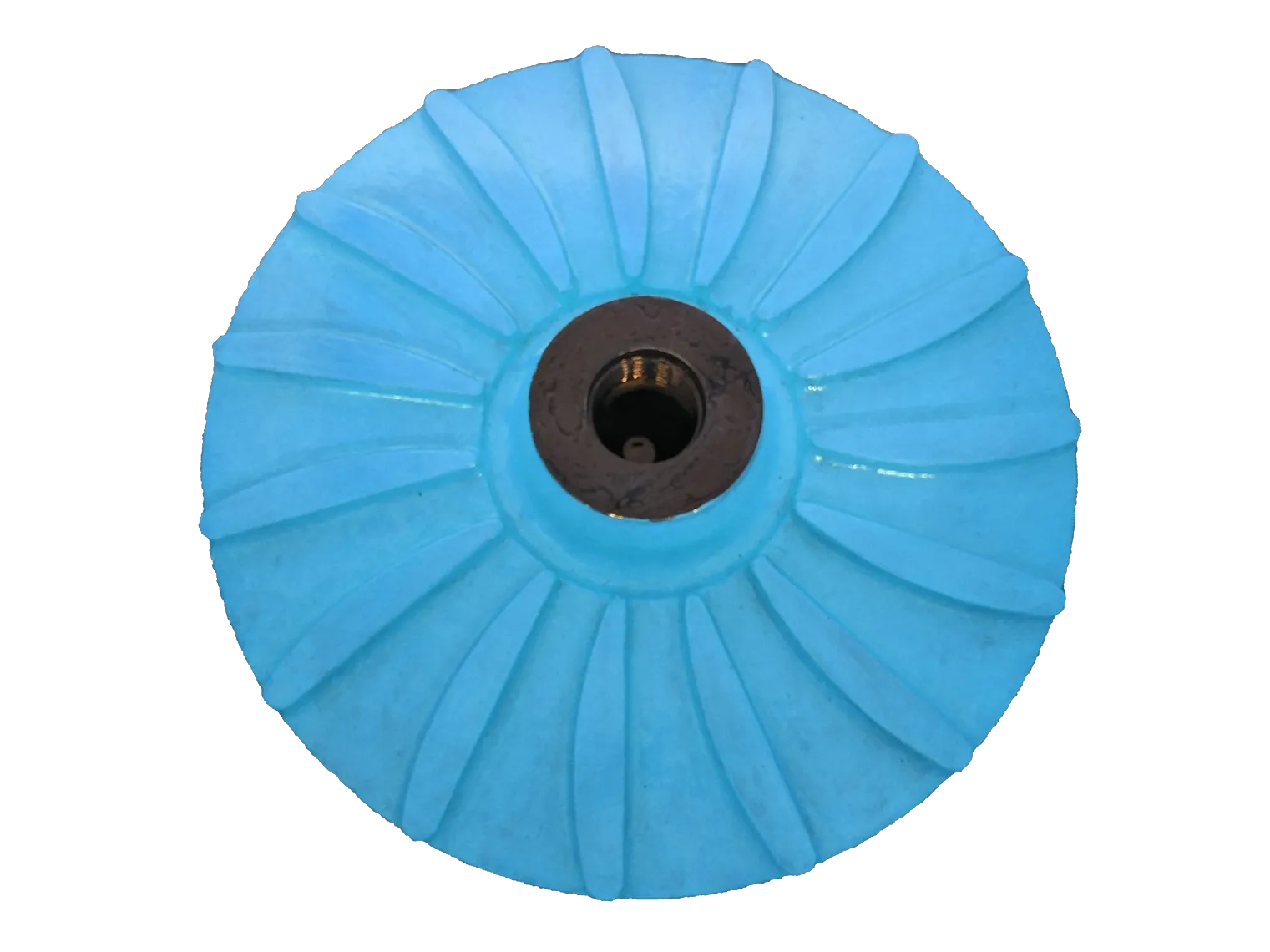

Pump Wear Parts G10147 Metal

In the realm of industrial applications, the slurry pump stands as a quintessential component for handling and transporting materials laden with solids. These robust pumps are engineered to withstand the abrasive nature of slurries, ensuring efficient and reliable operations across various industries. Their versatility and durability make them indispensable in sectors such as mining, construction, agriculture, and wastewater management.

Within wastewater treatment facilities, slurry pumps are essential for the movement of sludge and other dense materials. They help in the transfer of waste from one stage to another, ensuring that the treatment processes remain uninterrupted and efficient. The ability of these pumps to handle varying viscosities and particle sizes makes them ideal for the diverse challenges presented in wastewater management. The design considerations for slurry pumps include factors such as wear resistance, seal integrity, and energy efficiency. Modern advancements have led to the development of pumps with enhanced materials like high-chrome alloys and elastomers, which improve wear resistance and pump longevity. Seal technology has also evolved to minimize leaks and reduce maintenance downtime, thus increasing operational reliability and reducing costs. Energy efficiency is a key focus in the design and selection of slurry pumps, as it directly correlates with the operational expenses of any installation. Pumping systems that use optimized impeller designs and variable frequency drives (VFDs) have significantly improved the energy profiles of slurry pumping applications, aligning with global sustainability goals. The importance of proper maintenance and monitoring of slurry pumps cannot be overstated. Regular inspections, combined with data-driven insights from predictive maintenance technologies, enhance the lifespan of the pumps and reduce the chances of unexpected downtimes. Implementing a proactive maintenance strategy ensures that these critical systems continue to operate at peak efficiency. In summary, slurry pumps serve a pivotal function across numerous industries by providing a robust solution for handling abrasive and viscous materials. Their ability to operate under harsh conditions while maintaining efficiency and reliability makes them a cornerstone technology for modern industry. As environmental considerations and operational efficiency become increasingly important, the role of slurry pumps in sustainable practices and industrial productivity continues to grow, solidifying their status as an essential component in the industrial landscape.

Within wastewater treatment facilities, slurry pumps are essential for the movement of sludge and other dense materials. They help in the transfer of waste from one stage to another, ensuring that the treatment processes remain uninterrupted and efficient. The ability of these pumps to handle varying viscosities and particle sizes makes them ideal for the diverse challenges presented in wastewater management. The design considerations for slurry pumps include factors such as wear resistance, seal integrity, and energy efficiency. Modern advancements have led to the development of pumps with enhanced materials like high-chrome alloys and elastomers, which improve wear resistance and pump longevity. Seal technology has also evolved to minimize leaks and reduce maintenance downtime, thus increasing operational reliability and reducing costs. Energy efficiency is a key focus in the design and selection of slurry pumps, as it directly correlates with the operational expenses of any installation. Pumping systems that use optimized impeller designs and variable frequency drives (VFDs) have significantly improved the energy profiles of slurry pumping applications, aligning with global sustainability goals. The importance of proper maintenance and monitoring of slurry pumps cannot be overstated. Regular inspections, combined with data-driven insights from predictive maintenance technologies, enhance the lifespan of the pumps and reduce the chances of unexpected downtimes. Implementing a proactive maintenance strategy ensures that these critical systems continue to operate at peak efficiency. In summary, slurry pumps serve a pivotal function across numerous industries by providing a robust solution for handling abrasive and viscous materials. Their ability to operate under harsh conditions while maintaining efficiency and reliability makes them a cornerstone technology for modern industry. As environmental considerations and operational efficiency become increasingly important, the role of slurry pumps in sustainable practices and industrial productivity continues to grow, solidifying their status as an essential component in the industrial landscape.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024