-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 04:48

Back to list

slurry pumps specification

Slurry pumps are an essential component in a myriad of industries, from mining and mineral processing to wastewater management and construction. Understanding the detailed specifications of slurry pumps is crucial for selecting the right type for your application and optimizing system performance. Delving into the intricacies of slurry pumps specification enhances not only operational efficiency but also fosters a comprehension grounded in real-world application and authoritative expertise.

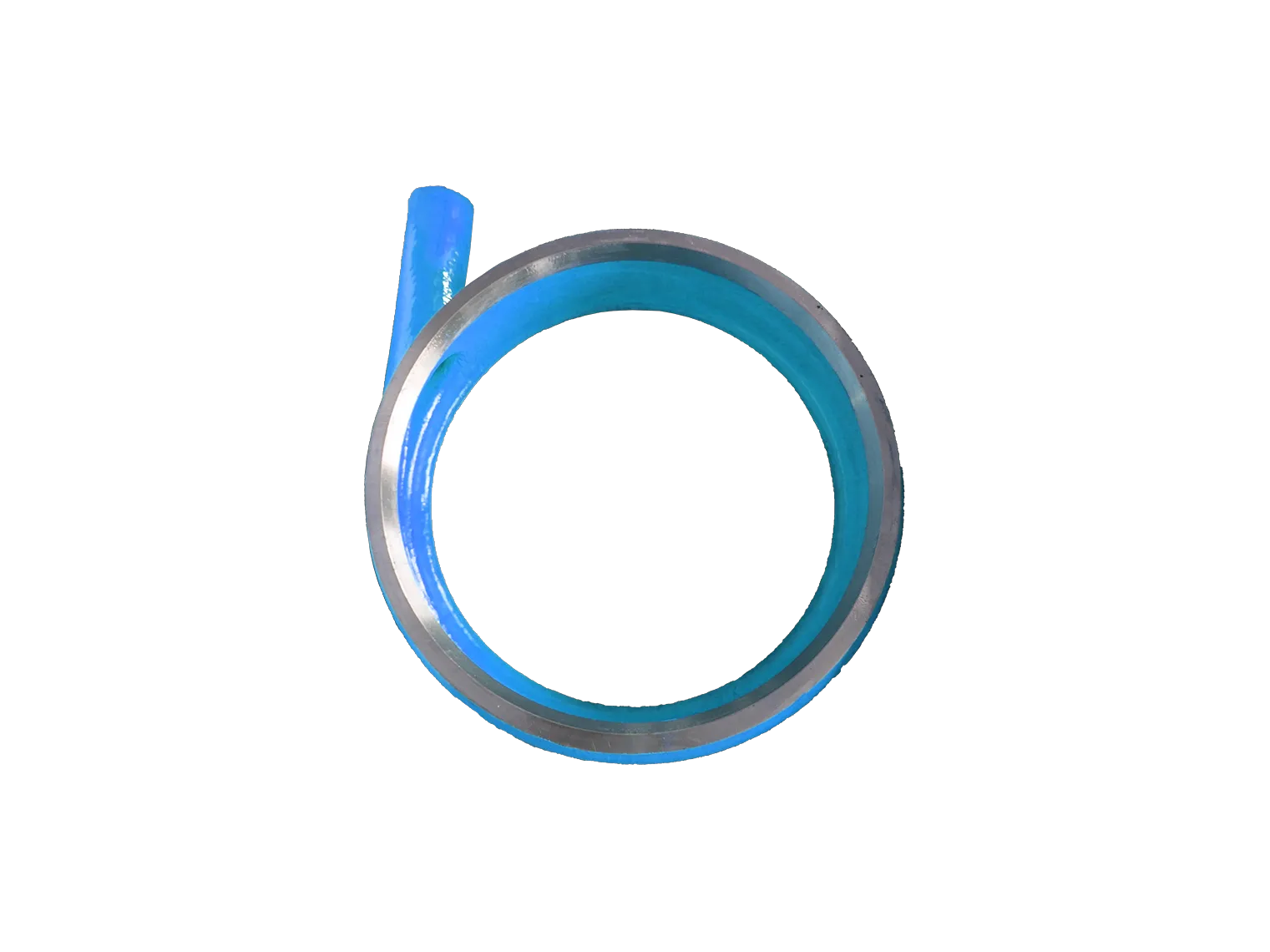

The concentration and type of solids in the slurry significantly impact pump performance. Specifications will typically address the percentage of solids by weight, particle size distribution, and the slurry's specific gravity. These factors dictate the pump's capacity, and understanding them is key to preventing issues like clogging or excessive wear, which can lead to increased downtimes and maintenance costs. Seal and Bearing Design Seal integrity is paramount in maintaining the durability of a slurry pump. Pump specifications often feature advanced seal designs, such as expeller, dynamic, or mechanical seals, tailored to prevent leakage and withstand abrasive damage. Additionally, bearings within slurry pumps are designed to endure axial and radial loads, often specified with lifecycle expectations that account for the challenging operating environments inherent to slurry pumping. Installation and Maintenance Considerations Ease of installation and ongoing maintenance requirements are critical components of slurry pump specifications. Pumps that facilitate straightforward installation and enable easy access for inspection and maintenance reduce downtime and enhance productivity. Many slurry pumps are designed with replaceable liners and impellers, allowing for extended service life and decreased long-term operational costs. System Integration and Customization The choice of a slurry pump must consider its integration within an existing system. Specifications tailored to specific industry needs offer options for variable speed drives, automation capabilities, and compatibility with ancillary equipment such as separators or thickeners. Customization options are often available from manufacturers, allowing for precise alignment with unusual or particularly demanding applications. In conclusion, comprehending the detailed specifications of slurry pumps is fundamental to achieving peak performance and reliability. By focusing on the application-specific requirements and leveraging expertise in material selection, design intricacies, and maintenance strategies, industries can significantly enhance their operational success. The informed selection of a slurry pump not only augments efficiency but also preserves capital investment, reinforcing trust and authority in industrial engineering solutions.

The concentration and type of solids in the slurry significantly impact pump performance. Specifications will typically address the percentage of solids by weight, particle size distribution, and the slurry's specific gravity. These factors dictate the pump's capacity, and understanding them is key to preventing issues like clogging or excessive wear, which can lead to increased downtimes and maintenance costs. Seal and Bearing Design Seal integrity is paramount in maintaining the durability of a slurry pump. Pump specifications often feature advanced seal designs, such as expeller, dynamic, or mechanical seals, tailored to prevent leakage and withstand abrasive damage. Additionally, bearings within slurry pumps are designed to endure axial and radial loads, often specified with lifecycle expectations that account for the challenging operating environments inherent to slurry pumping. Installation and Maintenance Considerations Ease of installation and ongoing maintenance requirements are critical components of slurry pump specifications. Pumps that facilitate straightforward installation and enable easy access for inspection and maintenance reduce downtime and enhance productivity. Many slurry pumps are designed with replaceable liners and impellers, allowing for extended service life and decreased long-term operational costs. System Integration and Customization The choice of a slurry pump must consider its integration within an existing system. Specifications tailored to specific industry needs offer options for variable speed drives, automation capabilities, and compatibility with ancillary equipment such as separators or thickeners. Customization options are often available from manufacturers, allowing for precise alignment with unusual or particularly demanding applications. In conclusion, comprehending the detailed specifications of slurry pumps is fundamental to achieving peak performance and reliability. By focusing on the application-specific requirements and leveraging expertise in material selection, design intricacies, and maintenance strategies, industries can significantly enhance their operational success. The informed selection of a slurry pump not only augments efficiency but also preserves capital investment, reinforcing trust and authority in industrial engineering solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024