-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 00:33

Back to list

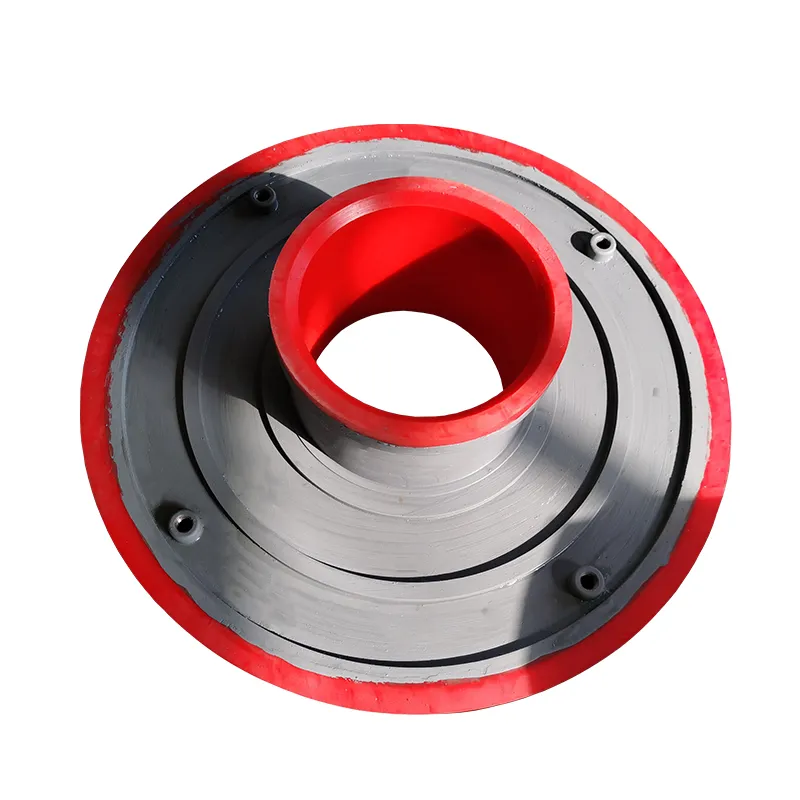

slurry pump spare parts factory

Slurry pump spare parts play a crucial role in various industrial processes, ensuring the smooth and efficient operation of slurry pumps. Choosing the right factory for sourcing these components is paramount to maintaining the longevity and performance of your equipment. This article delves into the key aspects of selecting a slurry pump spare parts factory that excels in experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness is arguably the most critical metric when selecting a slurry pump spare parts factory. Trust is built on transparency, reliability, and excellent customer service. A trustworthy factory is upfront about its production processes, pricing, and delivery timelines. It provides clear communication channels, ensuring clients are informed and supported throughout their engagement. Testimonials, case studies, and client reviews offer insight into the factory’s reliability and the satisfaction of previous clients. Moreover, an unwavering commitment to sustainability and ethical practices enhances a factory’s trustworthiness. With increasing global emphasis on environmentally responsible practices, clients are more inclined to engage with factories that prioritize sustainability in their manufacturing processes. This commitment not only preserves environmental resources but also reflects a factory’s dedication to industry leadership and forward-thinking. Choosing the right slurry pump spare parts factory requires a nuanced evaluation of experience, expertise, authoritativeness, and trustworthiness. An experienced factory that demonstrates unparalleled expertise and holds authoritative standing in the industry, while being reliable and transparent, is well-positioned to meet the complex needs of its clients. Such a factory stands as an advantageous partner, ensuring that the crucial components sustaining your operations are unmatched in quality and reliability. Innovative technologies and materials continue to redefine the landscape of slurry pump manufacturing. A factory that actively invests in innovation proves its commitment to pushing the boundaries of product quality and pump efficiency. Emerging technologies, such as 3D printing and advanced material composites, are at the forefront of this revolution, offering unprecedented opportunities for customization and improved lifecycle performance of pump parts. In conclusion, the selection of a slurry pump spare parts factory goes beyond merely fulfilling a supply chain requirement. It involves partnering with a provider whose experience, expertise, authoritativeness, and trustworthiness align with your company’s operational goals and values. Such a partnership not only ensures the uninterrupted function of slurry pumps but also contributes to the broader objectives of operational excellence and sustainability. Demand for high-performance slurry pump spare parts continues to grow, making the choice of factory a strategic decision with lasting impact.

Trustworthiness is arguably the most critical metric when selecting a slurry pump spare parts factory. Trust is built on transparency, reliability, and excellent customer service. A trustworthy factory is upfront about its production processes, pricing, and delivery timelines. It provides clear communication channels, ensuring clients are informed and supported throughout their engagement. Testimonials, case studies, and client reviews offer insight into the factory’s reliability and the satisfaction of previous clients. Moreover, an unwavering commitment to sustainability and ethical practices enhances a factory’s trustworthiness. With increasing global emphasis on environmentally responsible practices, clients are more inclined to engage with factories that prioritize sustainability in their manufacturing processes. This commitment not only preserves environmental resources but also reflects a factory’s dedication to industry leadership and forward-thinking. Choosing the right slurry pump spare parts factory requires a nuanced evaluation of experience, expertise, authoritativeness, and trustworthiness. An experienced factory that demonstrates unparalleled expertise and holds authoritative standing in the industry, while being reliable and transparent, is well-positioned to meet the complex needs of its clients. Such a factory stands as an advantageous partner, ensuring that the crucial components sustaining your operations are unmatched in quality and reliability. Innovative technologies and materials continue to redefine the landscape of slurry pump manufacturing. A factory that actively invests in innovation proves its commitment to pushing the boundaries of product quality and pump efficiency. Emerging technologies, such as 3D printing and advanced material composites, are at the forefront of this revolution, offering unprecedented opportunities for customization and improved lifecycle performance of pump parts. In conclusion, the selection of a slurry pump spare parts factory goes beyond merely fulfilling a supply chain requirement. It involves partnering with a provider whose experience, expertise, authoritativeness, and trustworthiness align with your company’s operational goals and values. Such a partnership not only ensures the uninterrupted function of slurry pumps but also contributes to the broader objectives of operational excellence and sustainability. Demand for high-performance slurry pump spare parts continues to grow, making the choice of factory a strategic decision with lasting impact.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024