-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 06, 2025 01:22

Back to list

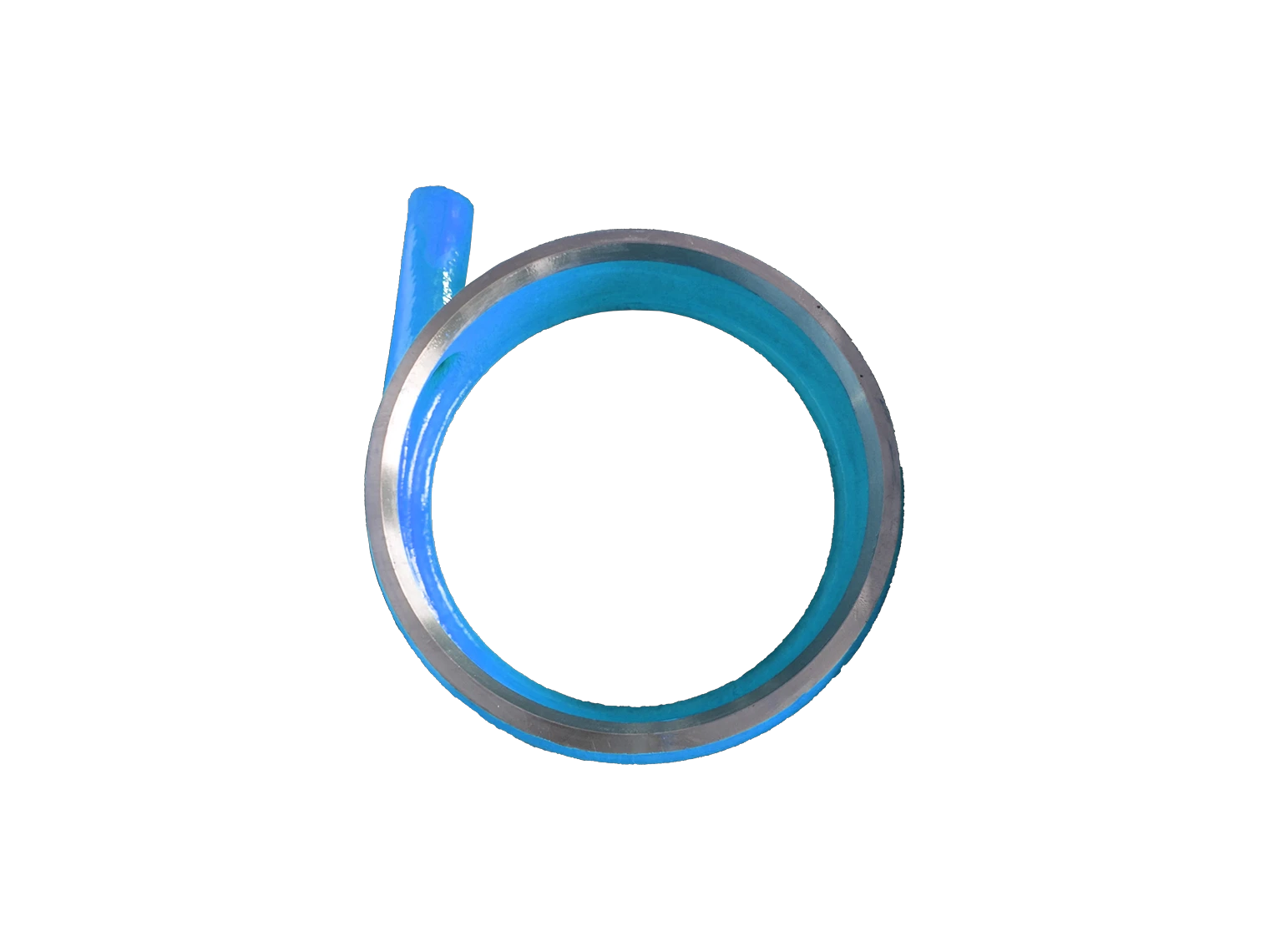

slurry pump spare parts

When it comes to maintaining efficient operations in industries such as mining, construction, and wastewater management, the role of slurry pumps is indispensable. However, as with any mechanical component, they are subject to wear and tear, necessitating the replacement of slurry pump spare parts. To ensure optimal performance and longevity of slurry pump systems, it is crucial to understand the significance of high-quality spare parts and their impact on operational dynamics.

Trustworthiness is another pillar on which sound slurry pump maintenance rests. Partnering with reputable suppliers who are transparent about their manufacturing processes and the sourcing of materials can greatly affect the trust levels. Establishing a long-term relationship with trusted suppliers means having access to genuine parts that are crucial for maintaining the operational integrity of slurry pumps. Moreover, it assures consistent quality, cutting down the risk of system failures due to part incompatibility or defects. Real-world experiences further underscore the importance of investing in high-grade slurry pump spare parts. Industry case studies have shown that companies who prioritize quality over cost for their spare parts witness reduced operational downtimes and a marked improvement in pump lifecycle cost management. Anecdotal evidence from plant maintenance engineers often reveals scenarios where subpar spare parts resulted in cascading system failures, emphasizing that the short-term savings from purchasing cheaper components are often overshadowed by the long-term costs associated with frequent replacements and repairs. In conclusion, maintaining high operational standards for slurry pumps requires a thoughtful approach to selecting spare parts, rooted in experience, expertise, and an unwavering commitment to quality. Through authoritative insights and trustworthy partnerships, businesses can ensure their slurry pump systems remain efficient, reliable, and cost-effective. Understanding and implementing these principles not only leads to enhanced performance but also cements a business's reputation for operational excellence in a competitive market.

Trustworthiness is another pillar on which sound slurry pump maintenance rests. Partnering with reputable suppliers who are transparent about their manufacturing processes and the sourcing of materials can greatly affect the trust levels. Establishing a long-term relationship with trusted suppliers means having access to genuine parts that are crucial for maintaining the operational integrity of slurry pumps. Moreover, it assures consistent quality, cutting down the risk of system failures due to part incompatibility or defects. Real-world experiences further underscore the importance of investing in high-grade slurry pump spare parts. Industry case studies have shown that companies who prioritize quality over cost for their spare parts witness reduced operational downtimes and a marked improvement in pump lifecycle cost management. Anecdotal evidence from plant maintenance engineers often reveals scenarios where subpar spare parts resulted in cascading system failures, emphasizing that the short-term savings from purchasing cheaper components are often overshadowed by the long-term costs associated with frequent replacements and repairs. In conclusion, maintaining high operational standards for slurry pumps requires a thoughtful approach to selecting spare parts, rooted in experience, expertise, and an unwavering commitment to quality. Through authoritative insights and trustworthy partnerships, businesses can ensure their slurry pump systems remain efficient, reliable, and cost-effective. Understanding and implementing these principles not only leads to enhanced performance but also cements a business's reputation for operational excellence in a competitive market.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024