-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 05:22

Back to list

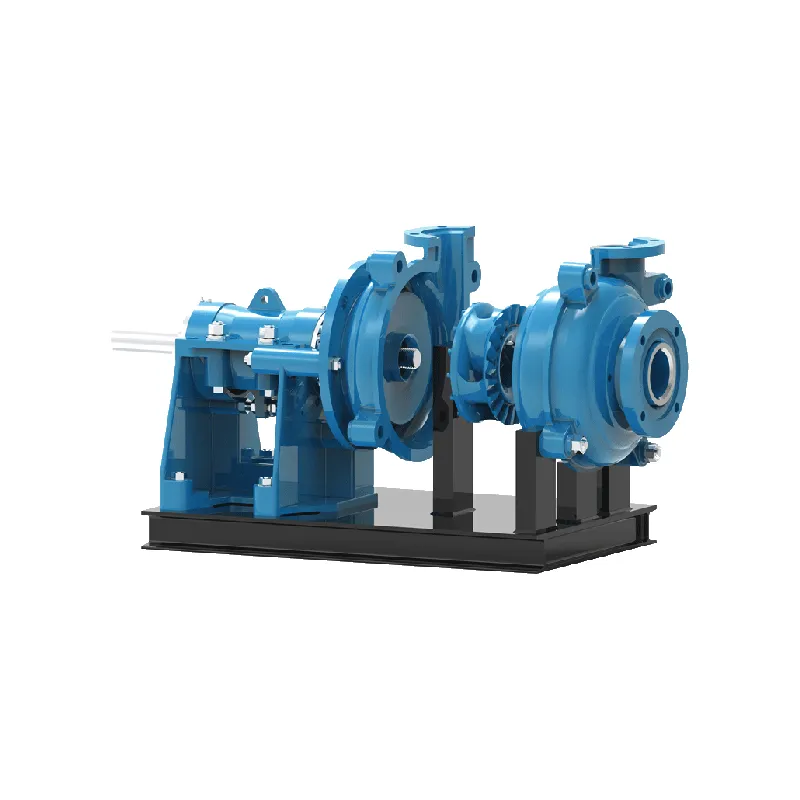

slurry pump spare and wear parts

Slurry pumps and their spare and wear parts are integral components in industries where the transportation of abrasive, high-density slurries is routine. Understanding the nuances of these components not only helps in maximizing operational efficiency but also ensures longevity and reliability in harsh working conditions.

Authoritativeness in the domain of slurry pump spare parts emerges from a company's commitment to innovation and quality control. Leading manufacturers employ state-of-the-art technology in both the design and production stages. Advanced simulation software and rigorous quality testing protocols ensure each part meets specific criteria for performance, durability, and compatibility. This meticulous approach builds confidence in the products and solidifies the manufacturer's reputation in the market. Trustworthiness is further exemplified through transparent customer service and robust warranty programs. Accessibility to genuine parts, backed by expert support and advice, reassures users about the integrity of their pumping systems. Furthermore, installation guides, troubleshooting manuals, and easily accessible customer support lines are essential services provided by reputable manufacturers. The effectiveness of slurry pump spare and wear parts is not solely about longevity but also about efficiency. A well-maintained slurry pump reduces energy consumption, impacts operational costs, and minimizes the environmental footprint of industrial activities. Energy-efficient designs and eco-friendly materials align with global sustainability goals, making them not only a smart choice but also a responsible one. In conclusion, the world of slurry pump spare and wear parts is intricate and requires a blend of experience, expertise, authoritativeness, and trustworthiness for optimal use and maintenance. Companies that understand these components' complexity and apply best practices in their selection and upkeep are leaders in their respective industries. This commitment not only enhances operational efficiency but also reinforces their standing as ethical and reliable operators.

Authoritativeness in the domain of slurry pump spare parts emerges from a company's commitment to innovation and quality control. Leading manufacturers employ state-of-the-art technology in both the design and production stages. Advanced simulation software and rigorous quality testing protocols ensure each part meets specific criteria for performance, durability, and compatibility. This meticulous approach builds confidence in the products and solidifies the manufacturer's reputation in the market. Trustworthiness is further exemplified through transparent customer service and robust warranty programs. Accessibility to genuine parts, backed by expert support and advice, reassures users about the integrity of their pumping systems. Furthermore, installation guides, troubleshooting manuals, and easily accessible customer support lines are essential services provided by reputable manufacturers. The effectiveness of slurry pump spare and wear parts is not solely about longevity but also about efficiency. A well-maintained slurry pump reduces energy consumption, impacts operational costs, and minimizes the environmental footprint of industrial activities. Energy-efficient designs and eco-friendly materials align with global sustainability goals, making them not only a smart choice but also a responsible one. In conclusion, the world of slurry pump spare and wear parts is intricate and requires a blend of experience, expertise, authoritativeness, and trustworthiness for optimal use and maintenance. Companies that understand these components' complexity and apply best practices in their selection and upkeep are leaders in their respective industries. This commitment not only enhances operational efficiency but also reinforces their standing as ethical and reliable operators.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024