-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 02:28

Back to list

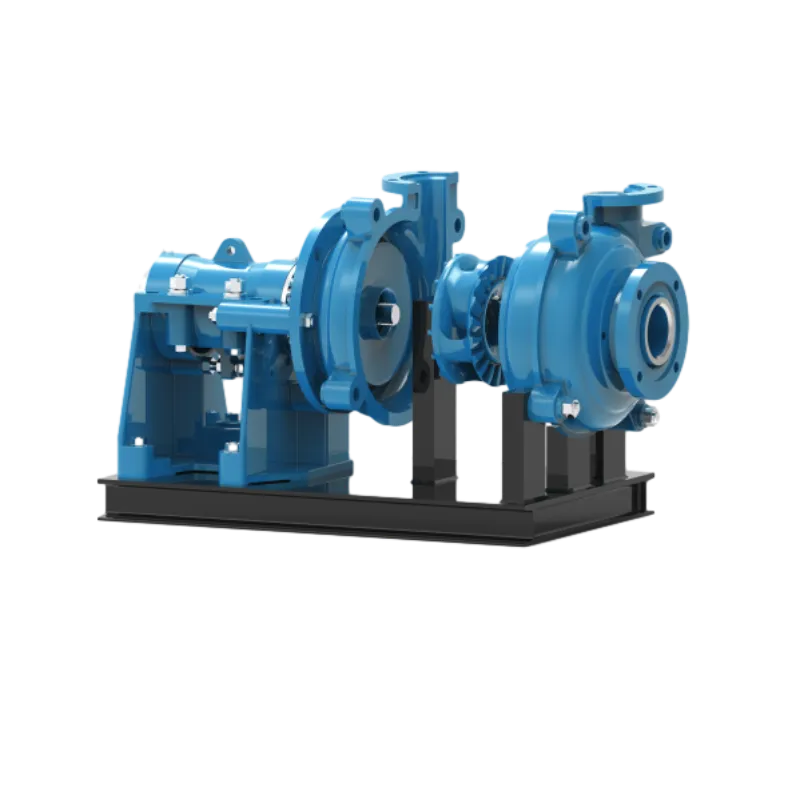

slurry pump sizing

Understanding the intricacies of slurry pump sizing is essential for industries dealing with solid-liquid mixtures. Achieving optimal performance requires not just selecting the right pump, but understanding the nuances of how these pumps function under varying conditions. Leveraging decades of experience in fluid dynamics and contaminated environments, this discussion delves into the critical factors influencing slurry pump sizing.

From an authoritative perspective, industry standards and best practices provide a framework within which professionals operate. Adhering to international guidelines like the Hydraulic Institute Standards and leveraging computational fluid dynamics (CFD) can aid in predicting performance and optimizing pump size. Field evidence from diverse applications, such as oil sand extraction or mineral processing, underscores the importance of such standards in ensuring uniformity and reliability across projects. Establishing trustworthiness in slurry pump sizing is about transparency and adaptability. A reputable manufacturer will provide detailed specifications and performance curves that illustrate how a pump will behave under specific conditions. Collaboration with such manufacturers ensures that the equipment adheres to the required specifications and can adapt to changes in the slurry properties or system configuration. An example from the construction industry highlights the impact of these elements During a construction dewatering project dealing with sandy water, a miscalculation in pump size led to frequent blockages and costly downtime. Re-evaluation with a focus on accurate slurry properties and system dynamics facilitated the selection of a more suitable pump, resulting in streamlined operations and significant cost savings. In summary, the journey to perfect slurry pump sizing is paved with meticulous assessment, knowledge of fluid and mechanical dynamics, and adherence to established engineering standards. This holistic approach not only ensures efficiency but also builds lasting trust in the product's performance in challenging environments. Prioritizing these factors will invariably lead to successful slurry management and longevity of pump infrastructure.

From an authoritative perspective, industry standards and best practices provide a framework within which professionals operate. Adhering to international guidelines like the Hydraulic Institute Standards and leveraging computational fluid dynamics (CFD) can aid in predicting performance and optimizing pump size. Field evidence from diverse applications, such as oil sand extraction or mineral processing, underscores the importance of such standards in ensuring uniformity and reliability across projects. Establishing trustworthiness in slurry pump sizing is about transparency and adaptability. A reputable manufacturer will provide detailed specifications and performance curves that illustrate how a pump will behave under specific conditions. Collaboration with such manufacturers ensures that the equipment adheres to the required specifications and can adapt to changes in the slurry properties or system configuration. An example from the construction industry highlights the impact of these elements During a construction dewatering project dealing with sandy water, a miscalculation in pump size led to frequent blockages and costly downtime. Re-evaluation with a focus on accurate slurry properties and system dynamics facilitated the selection of a more suitable pump, resulting in streamlined operations and significant cost savings. In summary, the journey to perfect slurry pump sizing is paved with meticulous assessment, knowledge of fluid and mechanical dynamics, and adherence to established engineering standards. This holistic approach not only ensures efficiency but also builds lasting trust in the product's performance in challenging environments. Prioritizing these factors will invariably lead to successful slurry management and longevity of pump infrastructure.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024