-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 17, 2025 17:50

Back to list

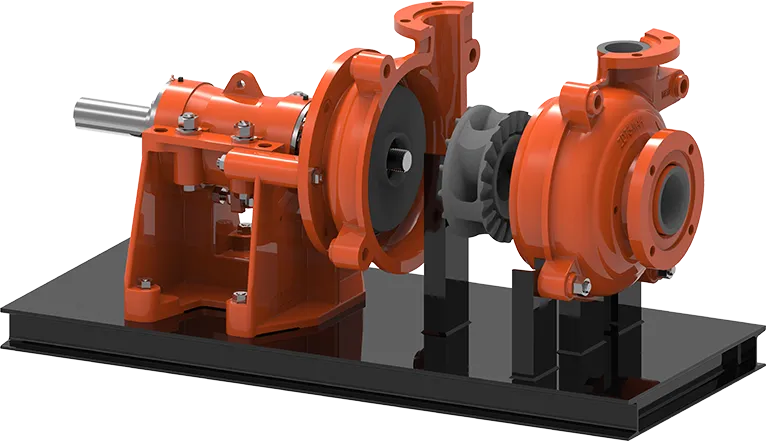

slurry pumps for sale

Slurry pumps are critical components in industries where the transportation of solid-laden media is crucial. These pumps are specifically designed and manufactured to handle high-wear processes, making them indispensable in mining, dredging, agriculture, and other industrial sectors. If you're considering investing in slurry pumps for your operations, it's crucial to understand various facets that ensure your purchase aligns with operational needs and contributes positively to your business goals.

Furthermore, the availability of spare parts and technical support is an integral component of the buying decision. Partnering with a reliable supplier who can provide quick access to genuine spare parts and expert technical support is essential in reducing downtime and maintaining operational continuity. Check for warranties and after-sales service networks to ensure you have robust backup when needed. Technological advancements in pump design, such as smart monitoring systems, have become prevalent. These systems can offer remote diagnostics, real-time performance tracking, and predictive maintenance alerts, further enhancing operational reliability and reducing downtime. Investing in technologically advanced slurry pumps not only provides immediate functional benefits but also aligns with long-term goals of operational efficiency and cost-effectiveness. Lastly, sustainability considerations are increasingly influencing equipment choices across industries. Pumps that are designed for energy efficiency and minimal environmental impact align well with contemporary corporate responsibility mandates. Companies looking to bolster their green credentials should consider the environmental footprint of their equipment purchases, including slurry pumps. In conclusion, purchasing slurry pumps is a significant decision that requires careful evaluation of technical requirements, material resilience, energy efficiency, compatibility, and after-sales support. The right pump ensures efficiency and longevity in demanding operational environments, validating the importance of an informed and strategic approach to equipment acquisition. Investing in the right slurry pump is an investment in the operational excellence and sustainability of your enterprise.

Furthermore, the availability of spare parts and technical support is an integral component of the buying decision. Partnering with a reliable supplier who can provide quick access to genuine spare parts and expert technical support is essential in reducing downtime and maintaining operational continuity. Check for warranties and after-sales service networks to ensure you have robust backup when needed. Technological advancements in pump design, such as smart monitoring systems, have become prevalent. These systems can offer remote diagnostics, real-time performance tracking, and predictive maintenance alerts, further enhancing operational reliability and reducing downtime. Investing in technologically advanced slurry pumps not only provides immediate functional benefits but also aligns with long-term goals of operational efficiency and cost-effectiveness. Lastly, sustainability considerations are increasingly influencing equipment choices across industries. Pumps that are designed for energy efficiency and minimal environmental impact align well with contemporary corporate responsibility mandates. Companies looking to bolster their green credentials should consider the environmental footprint of their equipment purchases, including slurry pumps. In conclusion, purchasing slurry pumps is a significant decision that requires careful evaluation of technical requirements, material resilience, energy efficiency, compatibility, and after-sales support. The right pump ensures efficiency and longevity in demanding operational environments, validating the importance of an informed and strategic approach to equipment acquisition. Investing in the right slurry pump is an investment in the operational excellence and sustainability of your enterprise.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024