-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 26, 2025 06:01

Back to list

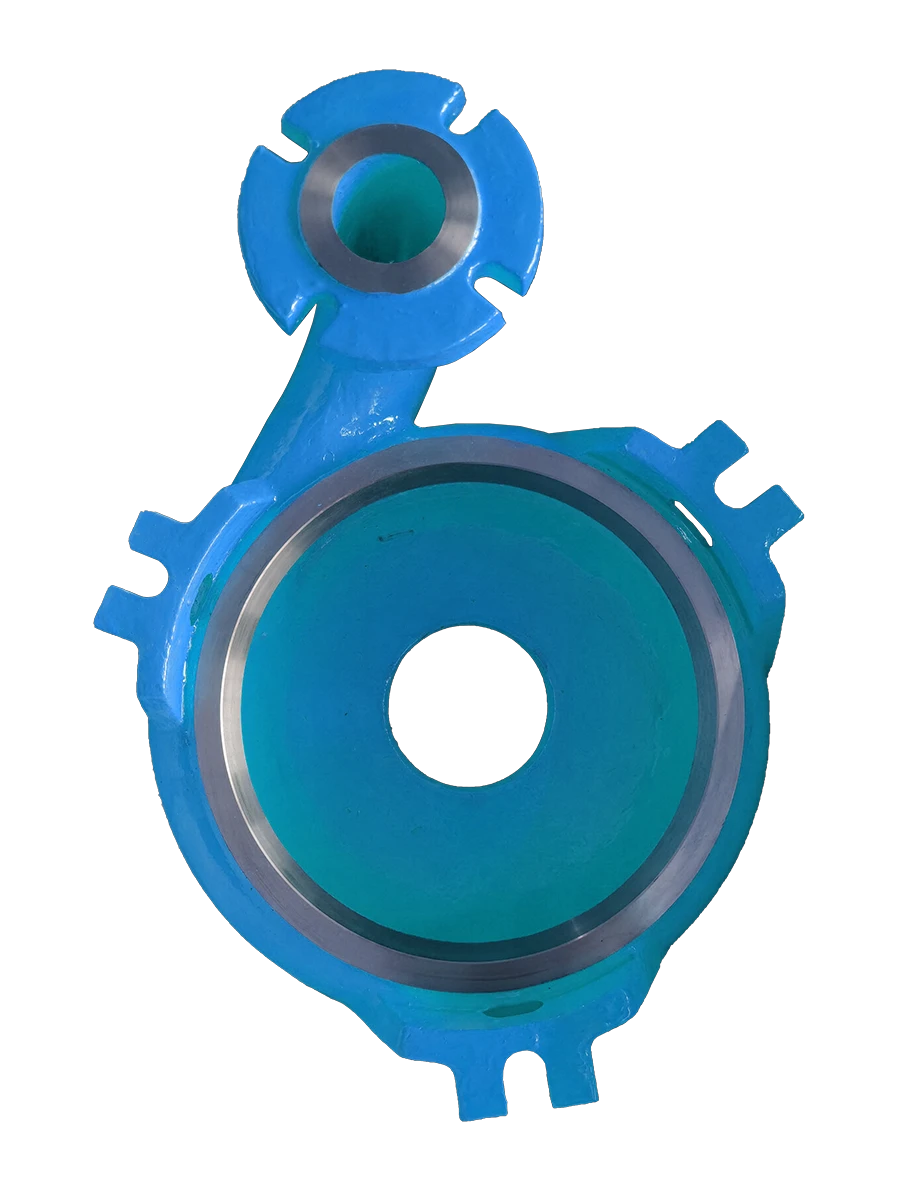

slurry pump seal

Slurry pump seals play a crucial role in a wide spectrum of industrial applications, from mining to wastewater treatment. They are indispensable components designed to prevent leakage, maintain pressure, and ensure the efficient operation of slurry pumps. Yet, selecting the right slurry pump seal can be a daunting process, especially without expert guidance. Therefore, understanding the intricacies of slurry pump seals—backed by experience, expertise, authoritativeness, and trustworthiness—is essential for any industry professional.

When it comes to credibility, relying on a trusted supplier with a track record of delivering high-quality seals cannot be overstated. Trustworthiness in the supplier manifests in their willingness to provide comprehensive support, encompassing design consultation, customization options, and on-site assistance. Especially in industries where reliability is paramount, such as in chemical processing or mining, working with reputable manufacturers and distributors who understand the critical nature of slurry pump seals offers assurance of performance and post-sale support. Innovative technologies are shaping the future of slurry pump seals, offering enhanced durability and efficiency. The rise of smart technology has revolutionized seal monitoring, allowing for real-time data collection and predictive maintenance that can alert users to potential seal failures before they lead to larger system issues. Such advancements illustrate the continuous development in the field, supported by the work of experts and researchers dedicated to pushing the boundaries of seal engineering. In conclusion, the selection and maintenance of slurry pump seals require more than a mere transactional approach; they demand a foundation of knowledge, authority, and trustworthiness. Through a combination of experience-driven practice and expert insights, industries can ensure their slurry pump systems remain robust and efficient under even the most challenging conditions. Strategically aligning oneself with industry leaders in seal technology signifies not only an investment in components but also in the assurance of operational excellence and long-term reliability.

When it comes to credibility, relying on a trusted supplier with a track record of delivering high-quality seals cannot be overstated. Trustworthiness in the supplier manifests in their willingness to provide comprehensive support, encompassing design consultation, customization options, and on-site assistance. Especially in industries where reliability is paramount, such as in chemical processing or mining, working with reputable manufacturers and distributors who understand the critical nature of slurry pump seals offers assurance of performance and post-sale support. Innovative technologies are shaping the future of slurry pump seals, offering enhanced durability and efficiency. The rise of smart technology has revolutionized seal monitoring, allowing for real-time data collection and predictive maintenance that can alert users to potential seal failures before they lead to larger system issues. Such advancements illustrate the continuous development in the field, supported by the work of experts and researchers dedicated to pushing the boundaries of seal engineering. In conclusion, the selection and maintenance of slurry pump seals require more than a mere transactional approach; they demand a foundation of knowledge, authority, and trustworthiness. Through a combination of experience-driven practice and expert insights, industries can ensure their slurry pump systems remain robust and efficient under even the most challenging conditions. Strategically aligning oneself with industry leaders in seal technology signifies not only an investment in components but also in the assurance of operational excellence and long-term reliability.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024