-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

slurry pump rubber spare parts

Understanding Slurry Pump Rubber Spare Parts Key Considerations and Benefits

Slurry pumps play a crucial role in various industrial applications, including mining, chemical processing, and wastewater treatment. Designed to handle abrasive and viscous materials, these pumps require durable and reliable components to ensure efficiency and longevity. A significant aspect of slurry pump maintenance and performance excellence lies in the quality of rubber spare parts. This article explores the importance of rubber spare parts in slurry pumps, their benefits, and critical considerations for selection and maintenance.

The Role of Rubber Spare Parts

Rubber spare parts are integral to slurry pumps as they provide protection against the harsh conditions inherent in transferring slurry mixtures. These parts often include impellers, wear plates, liners, and seals. Each component is designed to withstand the abrasive nature of slurry materials, which can contain solids ranging from sand, gravel, and minerals to chemical residues.

The elastomeric nature of rubber allows for flexibility and resilience, ensuring that these parts can endure variations in pressure and temperature during operation. The use of high-quality rubber not only enhances the durability of the pump but also decreases the likelihood of leaks and failures, which can lead to costly downtime and repairs.

Benefits of Using Rubber Spare Parts

1. Enhanced Durability Rubber parts are known for their ability to resist wear and tear, especially in abrasive environments. Utilizing high-grade rubber spare parts increases the lifespan of the slurry pump, as they can withstand the mechanical stress and chemical exposure typical of slurry applications.

2. Improved Efficiency Efficient operation of a slurry pump is critical for maintaining productivity. Rubber spare parts contribute to better sealing, reduced friction, and minimized energy consumption, ultimately leading to lower operational costs.

3. Cost-Effective Maintenance Regular maintenance of slurry pumps is essential to avoid significant breakdowns. Using rubber spare parts simplifies maintenance processes and reduces the frequency of replacements due to their resilience. This can translate to substantial savings for companies over time.

4. Customization and Versatility Rubber spare parts can be tailored to meet specific operational requirements. Manufacturers often provide a variety of rubber compounds designed for different applications, allowing for customization based on factors such as chemical compatibility, temperature resistance, and abrasion levels.

slurry pump rubber spare parts

5. Reduced Equipment Downtime With high-quality rubber spare parts, the likelihood of pump failures decreases. This reliability means that operators can schedule maintenance more effectively and minimize equipment downtime, which is vital for continuous production processes.

Considerations for Selection

When selecting rubber spare parts for slurry pumps, several factors should be considered

1. Material Compatibility Different types of rubber are resistant to various chemicals and conditions. Ensure the selected rubber material is compatible with the slurry being handled to avoid degradation and failure.

2. Hardness and Resilience Rubber parts come in various hardness levels, which can affect their performance under different conditions. It is essential to choose materials that provide the right balance of softness and durability for the application.

3. Manufacturer Reputation Partnering with reputable manufacturers who specialize in slurry pump components can make a significant difference in the quality of spare parts obtained. Researching suppliers and reading customer reviews can help in making informed decisions.

4. Availability and Lead Time Ensure that spare parts are readily available or that the supplier can provide them within a reasonable timeframe. Prolonged lead times may impact operations significantly.

5. Cost vs. Quality While it may be tempting to opt for lower-cost spare parts, this can lead to frequent breakdowns and higher costs in the long run. Evaluating the trade-off between cost and quality is crucial.

Conclusion

In the context of slurry pumps, the importance of rubber spare parts cannot be overstated. With their ability to withstand harsh conditions, enhance efficiency, and reduce maintenance costs, they are essential for optimal pump performance and longevity. By choosing the right materials and ensuring proper maintenance, industries can significantly benefit from reliable and efficient slurry pump operation. The investment in high-quality rubber spare parts is an essential step towards achieving operational excellence and minimizing downtime in slurry-handling applications.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

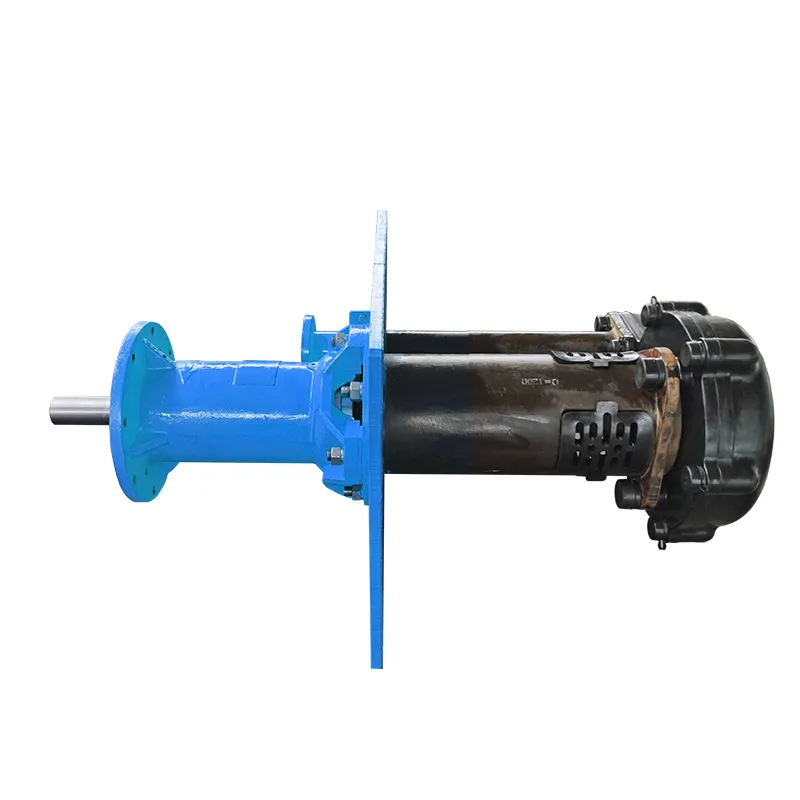

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024