-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 07, 2025 04:25

Back to list

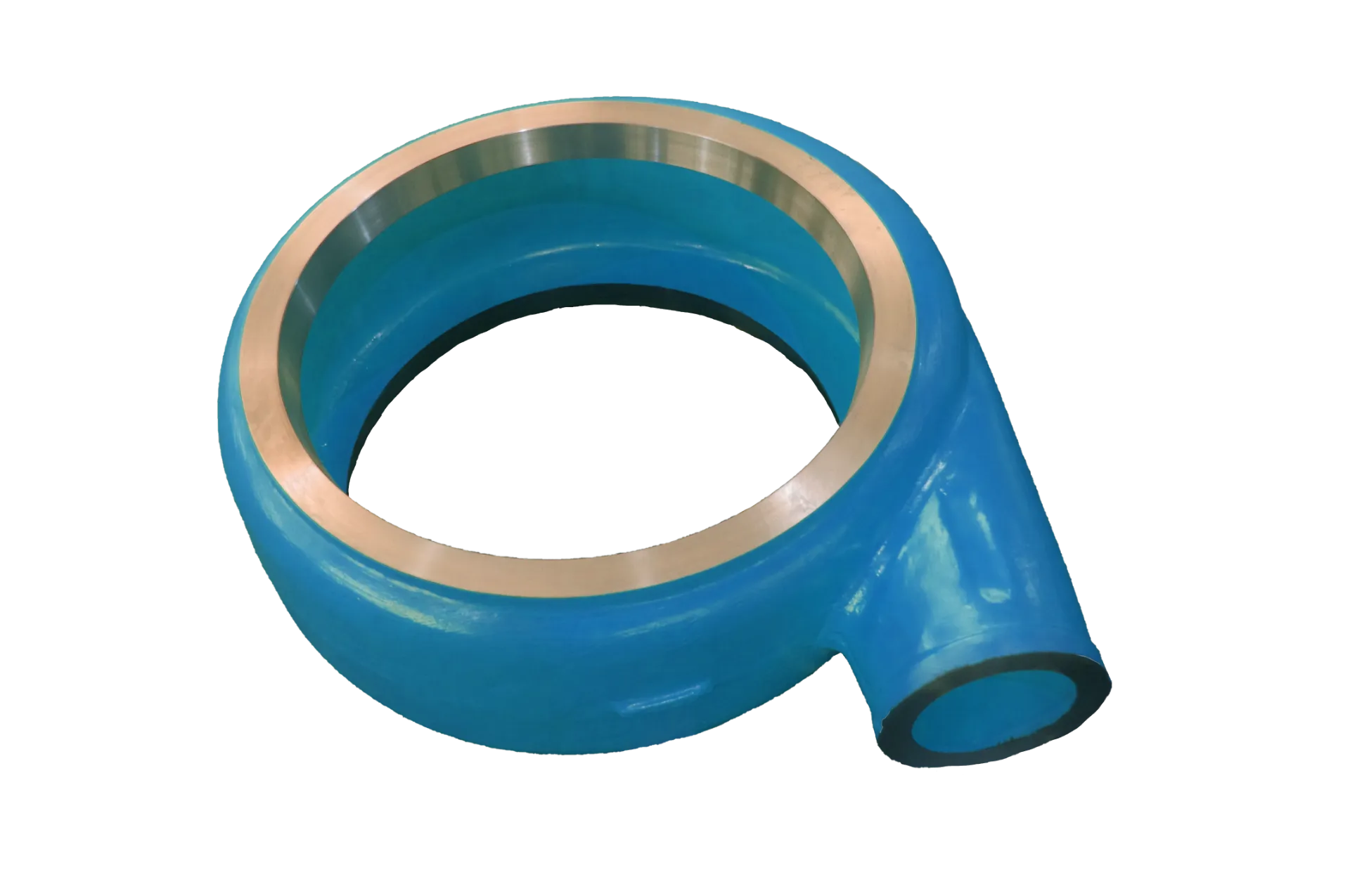

slurry pump rebuild

A slurry pump rebuild is not merely an option; it is a pivotal practice to enhance equipment longevity, efficiency, and performance. In industries where slurry pumps are integral — like mining, mineral processing, and waste management — the decision to rebuild a pump rather than replace it can bring substantial benefits. Here, we'll delve into the process and advantages of slurry pump rebuilding through the lens of seasoned expertise and industry authority.

Trustworthiness is built through documented success stories and a proven track record of excellence in pump refurbishing. Testimonials from long-term industrial clients who have experienced significant cost savings and enhanced operational efficiency after a pump rebuild can offer reassurance and foster trust. Offering warranties on rebuilt pumps is another layer of security that reputable companies provide, highlighting their confidence in the rebuild work performed. Moreover, the sustainability aspect of pump rebuilding cannot be overstated. By choosing to rebuild, companies contribute to environmental conservation by reducing waste and minimizing the carbon footprint associated with manufacturing new pumps. This aligns with the growing trend of adopting eco-friendly practices without compromising on machinery performance. In conclusion, the slurry pump rebuild process is a confluence of intricate technical know-how and strategic decision-making rooted in real-world industry experiences. The ability to effectively overhaul a pump, backed by specialized expertise and strong authoritative practices, not only ensures the restoration of optimal function but also delivers measurable economic and environmental benefits. Companies that leverage such rebuilds are in a better position to maintain competitive advantage, ensuring seamless operations and long-term sustainability in today's demanding industrial landscape.

Trustworthiness is built through documented success stories and a proven track record of excellence in pump refurbishing. Testimonials from long-term industrial clients who have experienced significant cost savings and enhanced operational efficiency after a pump rebuild can offer reassurance and foster trust. Offering warranties on rebuilt pumps is another layer of security that reputable companies provide, highlighting their confidence in the rebuild work performed. Moreover, the sustainability aspect of pump rebuilding cannot be overstated. By choosing to rebuild, companies contribute to environmental conservation by reducing waste and minimizing the carbon footprint associated with manufacturing new pumps. This aligns with the growing trend of adopting eco-friendly practices without compromising on machinery performance. In conclusion, the slurry pump rebuild process is a confluence of intricate technical know-how and strategic decision-making rooted in real-world industry experiences. The ability to effectively overhaul a pump, backed by specialized expertise and strong authoritative practices, not only ensures the restoration of optimal function but also delivers measurable economic and environmental benefits. Companies that leverage such rebuilds are in a better position to maintain competitive advantage, ensuring seamless operations and long-term sustainability in today's demanding industrial landscape.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024