-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 23:32

Back to list

slurry pump rebuild

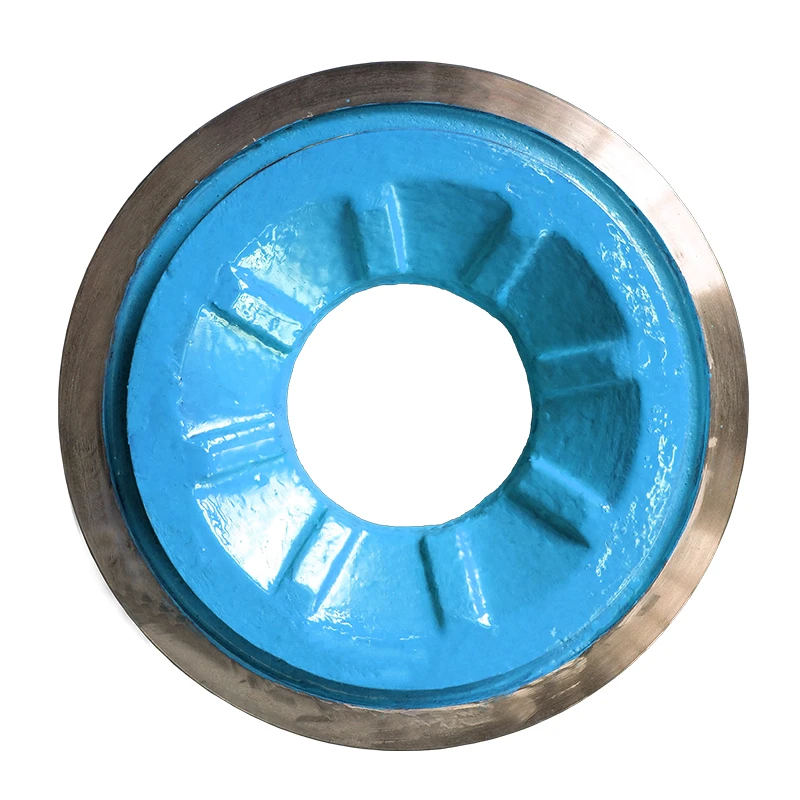

In the demanding world of industrial operations, the longevity and efficiency of equipment can significantly impact a company's productivity and profitability. One particular piece of equipment that often requires attention and maintenance is the slurry pump. Known for their pivotal role in applications involving the movement of mixtures of liquid and suspended solids, slurry pumps must be maintained rigorously to ensure seamless operations. Rebuilding a slurry pump, rather than opting for a complete replacement, presents not only a cost-effective solution but also a chance to optimize performance parameters befitting specific operational needs.

From an authoritative perspective, the guidance of certified and experienced professionals throughout the rebuild process ensures adherence to industry standards and best practices. This guarantees that the refurbished slurry pump not only meets original OEM (Original Equipment Manufacturer) performance standards but often surpasses them. Furthermore, the implementation of quality control measures at every stage of the rebuild process fosters trust. It assures stakeholders that the final product is reliable, efficient, and safe. This assurance is further bolstered by providing detailed documentation and performance test results post-rebuild, thereby reinforcing an image of trustworthiness and professionalism. Rebuilding a slurry pump also offers a unique opportunity for customization. By understanding the specific operational challenges and environment in which the pump will operate, experts can recommend modifications that tailor the pump's performance to its intended application. Whether it’s adjusting the impeller design for better flow dynamics or selecting coatings to resist particular chemical exposures, these customizations, guided by experience and authoritative insights, often lead to enhanced reliability and reduced downtime—transformative aspects that a mere replacement could not provide. Environmental considerations add another layer of relevance to choosing a rebuild over replacement. By refurbishing existing equipment, organizations reduce waste and lessen their environmental footprint. This aligns with modern corporate sustainability goals and displays a commitment to responsible resource management, enhancing the organization’s reputation for trustworthiness and social responsibility. In an era where operational efficiency and sustainability are paramount, the decision to rebuild rather than replace a slurry pump underscores a commitment to excellence. Through leveraging experience, expertise, and modern technological advancements, a slurry pump rebuild not only revitalizes essential equipment but does so with precision, innovation, and an eye towards the future. It's a process that, when executed with authoritative oversight and trustworthy practices, can provide significant, long-lasting benefits to industrial operations.

From an authoritative perspective, the guidance of certified and experienced professionals throughout the rebuild process ensures adherence to industry standards and best practices. This guarantees that the refurbished slurry pump not only meets original OEM (Original Equipment Manufacturer) performance standards but often surpasses them. Furthermore, the implementation of quality control measures at every stage of the rebuild process fosters trust. It assures stakeholders that the final product is reliable, efficient, and safe. This assurance is further bolstered by providing detailed documentation and performance test results post-rebuild, thereby reinforcing an image of trustworthiness and professionalism. Rebuilding a slurry pump also offers a unique opportunity for customization. By understanding the specific operational challenges and environment in which the pump will operate, experts can recommend modifications that tailor the pump's performance to its intended application. Whether it’s adjusting the impeller design for better flow dynamics or selecting coatings to resist particular chemical exposures, these customizations, guided by experience and authoritative insights, often lead to enhanced reliability and reduced downtime—transformative aspects that a mere replacement could not provide. Environmental considerations add another layer of relevance to choosing a rebuild over replacement. By refurbishing existing equipment, organizations reduce waste and lessen their environmental footprint. This aligns with modern corporate sustainability goals and displays a commitment to responsible resource management, enhancing the organization’s reputation for trustworthiness and social responsibility. In an era where operational efficiency and sustainability are paramount, the decision to rebuild rather than replace a slurry pump underscores a commitment to excellence. Through leveraging experience, expertise, and modern technological advancements, a slurry pump rebuild not only revitalizes essential equipment but does so with precision, innovation, and an eye towards the future. It's a process that, when executed with authoritative oversight and trustworthy practices, can provide significant, long-lasting benefits to industrial operations.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024