-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 26, 2025 07:36

Back to list

slurry pump pdf

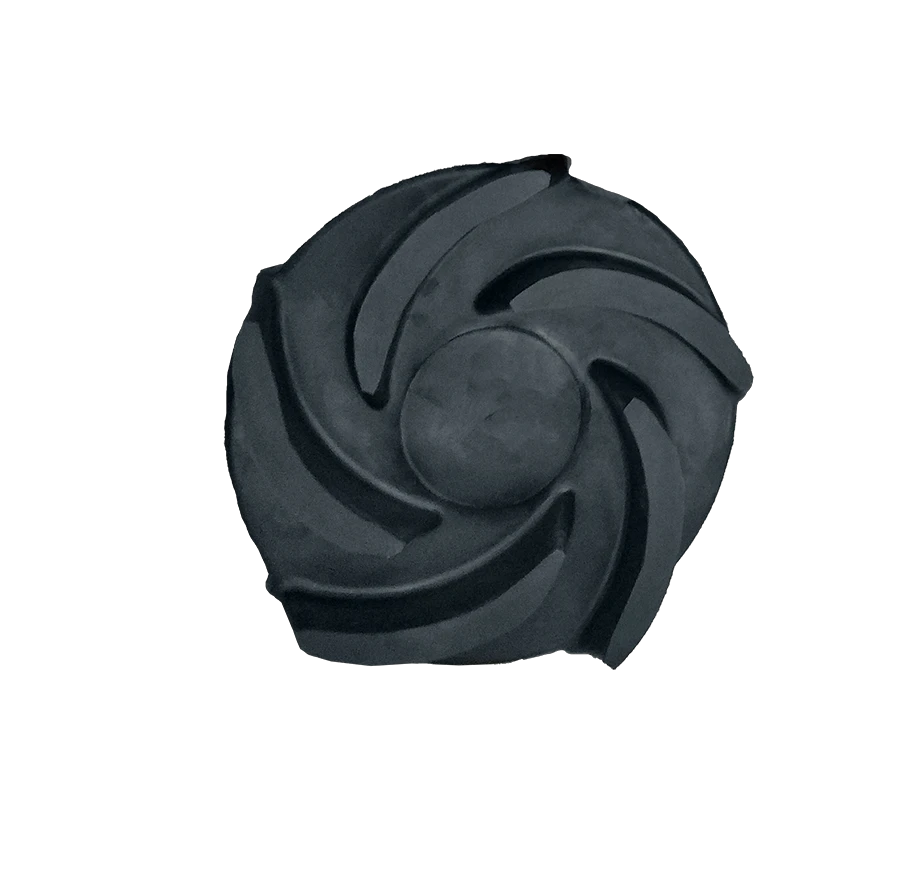

Slurry pumps are integral components in various industries that require the transportation of high-solid-content fluids. Crafting a product-focused article on slurry pumps is necessary to emphasize their application, performance, and reliability. The core structure of a slurry pump consists of a pump casing, an impeller, a liner, and a shaft sleeve, each part meticulously designed to handle abrasive and corrosive slurries.

One cannot overlook the environmental impact of slurry pumps. Modern innovations in sealing technologies, such as double mechanical seals and gland packing, prevent leakages, contributing to environmental safety and compliance with stringent regulations. These advancements not only affirm the pump’s reliability but also its role in promoting sustainable operations. When selecting a slurry pump, leveraging industry expertise is vital. Understanding the specific requirements of the slurry, including particle size, pH levels, and temperature, guides in choosing the most suitable pump. Expert consultation with manufacturers or suppliers can provide tailored solutions that align with operational needs and longevity expectations. Authoritativeness in the field of slurry pumps is established through continuous development and research. Leading manufacturers invest in R&D to improve pump designs, materials, and technologies. Collaborations with educational and research institutions further validate the authority of these manufacturers in delivering state-of-the-art solutions. As industries evolve, so do the demands on slurry pumping technologies. From digital transformations in pump monitoring to the development of eco-friendly materials, slurry pumps are at the forefront of industrial advancements. Investing in cutting-edge slurry pump technologies ensures competitiveness and adherence to modern industry standards. In conclusion, slurry pumps are indispensable in operations requiring the movement of slurry, characterized by their resilience, efficiency, and innovative developments. Leveraging expertise in material selection, energy efficiency, and maintenance protocols ensures their optimal performance and longevity, making them a reliable choice for industries worldwide. Players in this field must continue to innovate and adhere to best practices, ensuring that slurry pumps not only meet but exceed the demands of today's industrial landscape.

One cannot overlook the environmental impact of slurry pumps. Modern innovations in sealing technologies, such as double mechanical seals and gland packing, prevent leakages, contributing to environmental safety and compliance with stringent regulations. These advancements not only affirm the pump’s reliability but also its role in promoting sustainable operations. When selecting a slurry pump, leveraging industry expertise is vital. Understanding the specific requirements of the slurry, including particle size, pH levels, and temperature, guides in choosing the most suitable pump. Expert consultation with manufacturers or suppliers can provide tailored solutions that align with operational needs and longevity expectations. Authoritativeness in the field of slurry pumps is established through continuous development and research. Leading manufacturers invest in R&D to improve pump designs, materials, and technologies. Collaborations with educational and research institutions further validate the authority of these manufacturers in delivering state-of-the-art solutions. As industries evolve, so do the demands on slurry pumping technologies. From digital transformations in pump monitoring to the development of eco-friendly materials, slurry pumps are at the forefront of industrial advancements. Investing in cutting-edge slurry pump technologies ensures competitiveness and adherence to modern industry standards. In conclusion, slurry pumps are indispensable in operations requiring the movement of slurry, characterized by their resilience, efficiency, and innovative developments. Leveraging expertise in material selection, energy efficiency, and maintenance protocols ensures their optimal performance and longevity, making them a reliable choice for industries worldwide. Players in this field must continue to innovate and adhere to best practices, ensuring that slurry pumps not only meet but exceed the demands of today's industrial landscape.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024