-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 07, 2025 00:54

Back to list

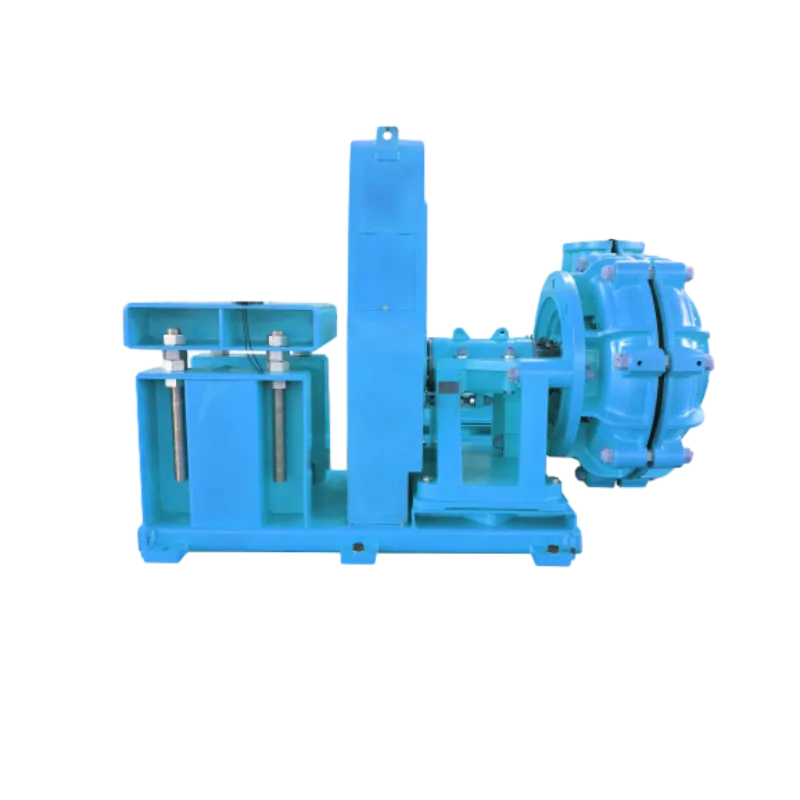

slurry pump mechanical seal

In the industrial realm, slurry pumps are crucial for handling abrasive and corrosive fluids. The mechanical seal, an essential component of these pumps, plays a pivotal role in ensuring efficient operation and longevity. This article delves into the intricacies of slurry pump mechanical seals, drawing upon decades of expert insights and real-world experiences to highlight their significance and best practices for maintenance.

Moreover, preventative maintenance holds the key to sustained seal performance. Regular inspections and monitoring of seal condition can preempt failures. For instance, vibration analysis and temperature monitoring are effective techniques used by industry leaders to detect potential seal deterioration before failure occurs, reducing costly pump downtimes. Trust in mechanical seal performance is also fortified by adherence to industry standards, like those set by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Manufacturers and users who follow these standards can ensure that their seals meet stringent quality and safety criteria, thereby enhancing overall system reliability. Real-world applications further testify to the efficacy of well-chosen and maintained mechanical seals. In a large-scale paper mill operation, a switch to improved mechanical seals cut production halts by nearly 40%, showcasing how critical these components are to continuous industrial processes. Eventually, the slurry pump mechanical seal's authoritative design and faultless functioning are not merely technical achievements but a blend of experienced insight, expert recommendations, and a commitment to quality. Industries embracing these principles see a marked improvement in operational efficiency and cost-effectiveness. By investing in quality components and adhering to best practices, businesses not only increase their operational efficiency but also build a resilient infrastructure that can adapt to the challenges of abrasive slurry environments. With careful selection, precise installation, and diligent maintenance of mechanical seals, industries can ensure their slurry pumps stand the test of time, bearing testimony to the invaluable role these components play in modern industrial applications.

Moreover, preventative maintenance holds the key to sustained seal performance. Regular inspections and monitoring of seal condition can preempt failures. For instance, vibration analysis and temperature monitoring are effective techniques used by industry leaders to detect potential seal deterioration before failure occurs, reducing costly pump downtimes. Trust in mechanical seal performance is also fortified by adherence to industry standards, like those set by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Manufacturers and users who follow these standards can ensure that their seals meet stringent quality and safety criteria, thereby enhancing overall system reliability. Real-world applications further testify to the efficacy of well-chosen and maintained mechanical seals. In a large-scale paper mill operation, a switch to improved mechanical seals cut production halts by nearly 40%, showcasing how critical these components are to continuous industrial processes. Eventually, the slurry pump mechanical seal's authoritative design and faultless functioning are not merely technical achievements but a blend of experienced insight, expert recommendations, and a commitment to quality. Industries embracing these principles see a marked improvement in operational efficiency and cost-effectiveness. By investing in quality components and adhering to best practices, businesses not only increase their operational efficiency but also build a resilient infrastructure that can adapt to the challenges of abrasive slurry environments. With careful selection, precise installation, and diligent maintenance of mechanical seals, industries can ensure their slurry pumps stand the test of time, bearing testimony to the invaluable role these components play in modern industrial applications.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024