-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 26, 2025 02:40

Back to list

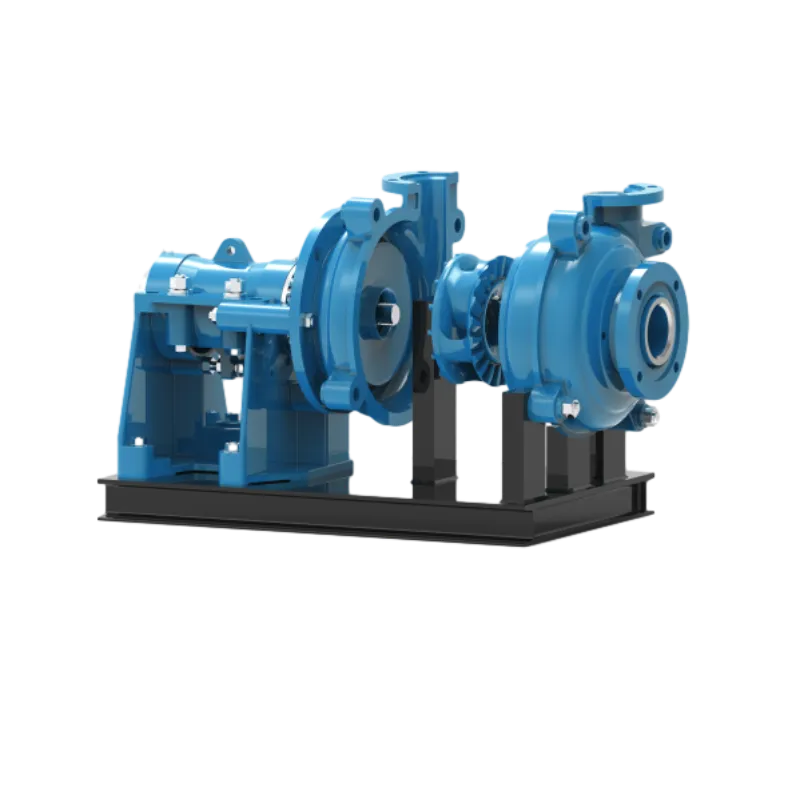

slurry pump meaning

Slurry pumps are integral components in industries from mining to wastewater treatment, designed to handle a mixture of liquid and solid particles, commonly known as slurry. These pumps serve a pivotal role in transporting abrasive and corrosive slurries, which necessitates careful consideration of their design and material composition.

A common issue faced by slurry pump operators is impeller erosion, a challenge that underscores the need for materials that offer superior wear resistance. High-chrome alloys, advanced polymers, and even ceramic coatings are among trusted solutions that show commendable endurance. Experts recommend routine assessments of erosion patterns, which can offer insights into the slurry dynamics within the system, guiding strategic adjustments or upgrades. The authoritativeness of slurry pump manufacturers is often reflected in their commitment to innovation and customer support. Trusted companies invest in research and development to produce pumps that not only meet the demanding conditions of modern industries but also anticipate future challenges. By offering detailed documentations, technical support, and comprehensive warranties, these manufacturers reinforce their credibility and maintain confidence in their products. Establishing trustworthiness involves transparency and a dedication to solving customer challenges. Expert consultation services offered by reputable providers assist customers in designing and installing tailor-made slurry transport systems that align with their specific industrial needs. This collaboration ensures that clients do not merely purchase equipment but rather gain a partner in achieving operational excellence. In conclusion, understanding the true meaning of slurry pumps goes beyond their basic function; it involves a blend of expertise, experience, and authoritative solutions that ensure their effective application in complex industrial environments. Their robust design is tailored to overcome the specific challenges presented by slurry, making them indispensable in industries where productivity and equipment reliability are paramount. Through careful selection, regular maintenance, and reliance on credible manufacturers, businesses can maximize the potential of slurry pumps, securing their operations against the inherent challenges of slurry handling.

A common issue faced by slurry pump operators is impeller erosion, a challenge that underscores the need for materials that offer superior wear resistance. High-chrome alloys, advanced polymers, and even ceramic coatings are among trusted solutions that show commendable endurance. Experts recommend routine assessments of erosion patterns, which can offer insights into the slurry dynamics within the system, guiding strategic adjustments or upgrades. The authoritativeness of slurry pump manufacturers is often reflected in their commitment to innovation and customer support. Trusted companies invest in research and development to produce pumps that not only meet the demanding conditions of modern industries but also anticipate future challenges. By offering detailed documentations, technical support, and comprehensive warranties, these manufacturers reinforce their credibility and maintain confidence in their products. Establishing trustworthiness involves transparency and a dedication to solving customer challenges. Expert consultation services offered by reputable providers assist customers in designing and installing tailor-made slurry transport systems that align with their specific industrial needs. This collaboration ensures that clients do not merely purchase equipment but rather gain a partner in achieving operational excellence. In conclusion, understanding the true meaning of slurry pumps goes beyond their basic function; it involves a blend of expertise, experience, and authoritative solutions that ensure their effective application in complex industrial environments. Their robust design is tailored to overcome the specific challenges presented by slurry, making them indispensable in industries where productivity and equipment reliability are paramount. Through careful selection, regular maintenance, and reliance on credible manufacturers, businesses can maximize the potential of slurry pumps, securing their operations against the inherent challenges of slurry handling.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024