-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 06:24

Back to list

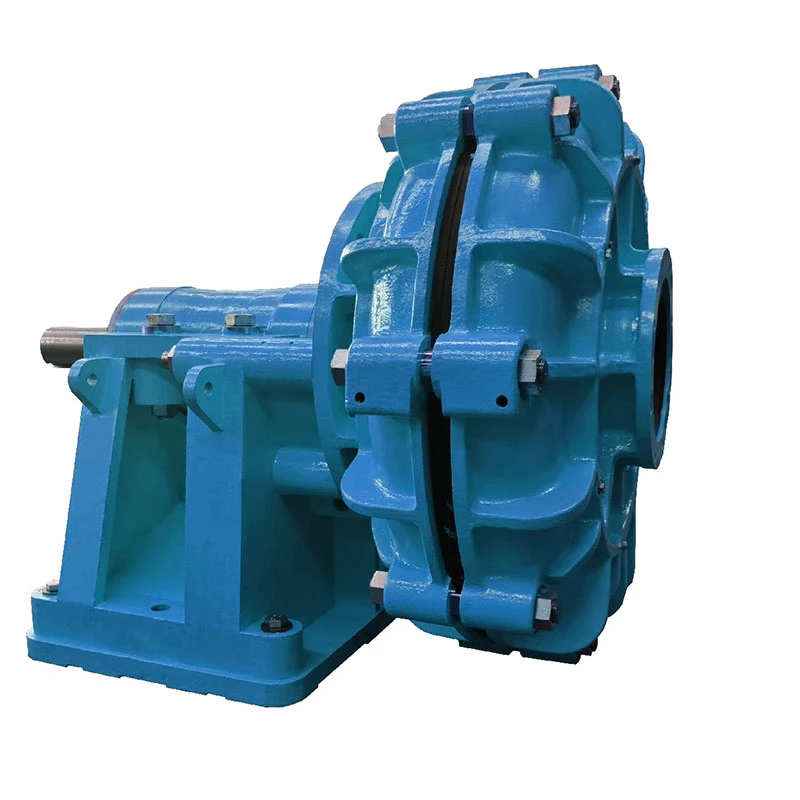

slurry pumping

Navigating the complex landscape of slurry pumping solutions requires a keen understanding of factors that influence pump selection, operation, and maintenance. As industries like mining, dredging, and wastewater management rely heavily on these systems for efficient material handling, mastering the intricacies of slurry pumping becomes pivotal.

Trustworthiness in supplier relationships also impacts the efficiency of slurry pumping systems. Choosing a reputable supplier who offers robust after-sales support is essential. Such partners provide not only quality pumps but also comprehensive training and spare parts availability, reducing downtime and operational disruptions. A competitive edge in the industry also comes from embracing technological advancements. Variable frequency drives (VFDs) and advanced control systems can optimize pump performance by adjusting pump speeds to match real-time demand, leading to energy savings and reduced operational stress. Furthermore, cutting-edge designs in impellers and volutes, tailored for specific slurry types, enhance efficiency and durability. In the context of environmental considerations, sustainable slurry pumping solutions are gaining traction. Energy-efficient pumps, designed to handle slurries with minimal resource consumption, contribute to decreased environmental impact. Additionally, pumps capable of processing alternative fuels or utilizing renewable energy sources present a forward-thinking approach to slurry management. In summary, the experience gleaned from working with a variety of slurry pumping systems underscores the importance of a finely tuned balance between selection, operation, and maintenance. Expertise in the nuances of different slurry types and the specific requirements they impose on pumps can propel productivity and cost-effectiveness. Authoritative advice from seasoned professionals, combined with trustworthy supplier relationships, can pave the way for successful and sustainable slurry handling operations. Embracing innovation and sustainability not only future-proofs slurry pumping systems but also aligns them with global trends toward ecological responsibility.

Trustworthiness in supplier relationships also impacts the efficiency of slurry pumping systems. Choosing a reputable supplier who offers robust after-sales support is essential. Such partners provide not only quality pumps but also comprehensive training and spare parts availability, reducing downtime and operational disruptions. A competitive edge in the industry also comes from embracing technological advancements. Variable frequency drives (VFDs) and advanced control systems can optimize pump performance by adjusting pump speeds to match real-time demand, leading to energy savings and reduced operational stress. Furthermore, cutting-edge designs in impellers and volutes, tailored for specific slurry types, enhance efficiency and durability. In the context of environmental considerations, sustainable slurry pumping solutions are gaining traction. Energy-efficient pumps, designed to handle slurries with minimal resource consumption, contribute to decreased environmental impact. Additionally, pumps capable of processing alternative fuels or utilizing renewable energy sources present a forward-thinking approach to slurry management. In summary, the experience gleaned from working with a variety of slurry pumping systems underscores the importance of a finely tuned balance between selection, operation, and maintenance. Expertise in the nuances of different slurry types and the specific requirements they impose on pumps can propel productivity and cost-effectiveness. Authoritative advice from seasoned professionals, combined with trustworthy supplier relationships, can pave the way for successful and sustainable slurry handling operations. Embracing innovation and sustainability not only future-proofs slurry pumping systems but also aligns them with global trends toward ecological responsibility.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024