-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

slurry pump impeller material

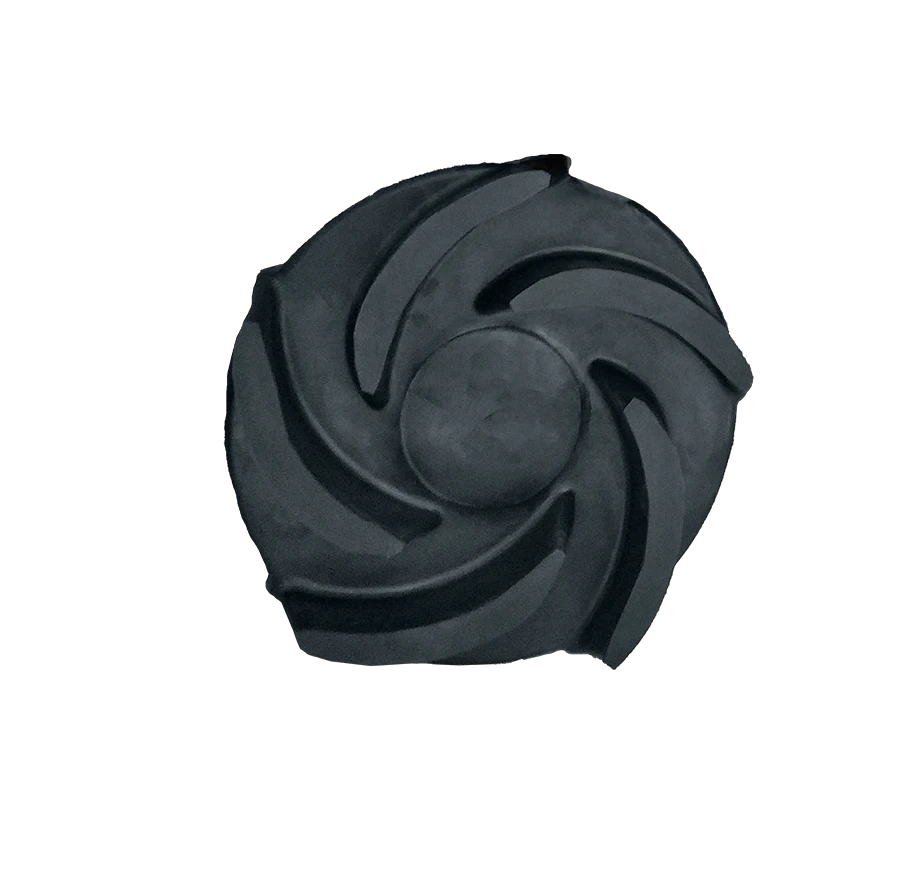

Understanding Slurry Pump Impeller Materials Key Considerations for Efficiency and Durability

Slurry pumps play a critical role in various industries, including mining, construction, and wastewater treatment. These pumps are specifically designed to handle abrasive and corrosive mixtures of water and solid particles, known as slurries. One of the most vital components of a slurry pump is its impeller, a rotating part that imparts energy to the fluid, enabling it to be transported through the system. The material used for the impeller directly impacts the pump's performance, longevity, and maintenance costs. This article explores different materials used for slurry pump impellers, their advantages, and considerations for selection.

Common Impeller Materials

1. Cast Iron Cast iron is one of the most widely used materials for slurry pump impellers. Its strength and affordability make it a popular choice for applications that do not involve highly abrasive slurries. Cast iron impellers provide good corrosion resistance and perform well in moderate temperature and pressure conditions. However, they may wear out quickly when handling very abrasive materials, leading to increased maintenance and replacement costs.

2. High Chrome Alloys High chrome alloys, often containing 24% or more chromium, are known for their exceptional hardness and resistance to wear. These alloys are ideal for handling highly abrasive slurries found in mining operations, as they can withstand severe conditions without significant wear. While the initial cost of high chrome impellers may be higher, their longevity and durability can result in lower total operating costs over time.

3. Rubber Linings Rubber-lined impellers are used in applications where chemical resistance and flexibility are essential. The rubber material can absorb shocks and provides excellent resistance to corrosion. This type of impeller is particularly effective in handling corrosive chemicals in the slurry, making it ideal for specific industrial processes. However, the rubber's wear resistance may not be as high as metal alloys, so careful consideration of the slurry composition is necessary.

4. Polyurethane Another alternative for slurry pump impellers is polyurethane, which offers a balance of flexibility, wear resistance, and chemical resistance. Polyurethane impellers can be engineered to meet specific application requirements, making them suitable for various slurries. They are often used in environments where a moderate amount of wear is expected and provide a longer service life compared to unlined metals.

5. Composite Materials In recent years, composite materials have gained popularity in slurry pump applications. These materials often combine the strengths of various substances to create lightweight, durable, and corrosion-resistant impellers. Composites can be engineered to withstand aggressive environments while reducing the load on the pump's drive system. They are particularly advantageous in highly corrosive or fluctuating temperature conditions.

slurry pump impeller material

Factors to Consider When Choosing Impeller Materials

When selecting impeller materials for slurry pumps, several factors must be considered

- Slurry Composition Understanding the type of solid particles and their abrasive properties is crucial. The impeller material must match the characteristics of the slurry to minimize wear and extend life. - Operating Conditions Temperature, pressure, and the presence of corrosive substances affect material choice. High-temperature slurries may require materials that can withstand thermal expansion and changes in viscosity.

- Cost While initial material costs are important, evaluating the long-term operational and maintenance costs is essential. Materials with higher upfront costs may offer better longevity and performance, thus proving more cost-effective over time.

- Pump Design The overall design of the slurry pump and its expected flow characteristics will influence the choice of impeller material. Specific designs may favor one material over another for achieving optimal efficiency.

Conclusion

Selecting the right material for slurry pump impellers is crucial for operational efficiency and durability. By understanding the properties of different materials, industries can make informed decisions that enhance performance and minimize downtime. Whether opting for cast iron, high chrome alloys, rubber, polyurethane, or composite materials, evaluating the specific requirements of the application will ensure that the slurry pump operates effectively, delivering reliable service in even the most challenging environments.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024