-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 13:26

Back to list

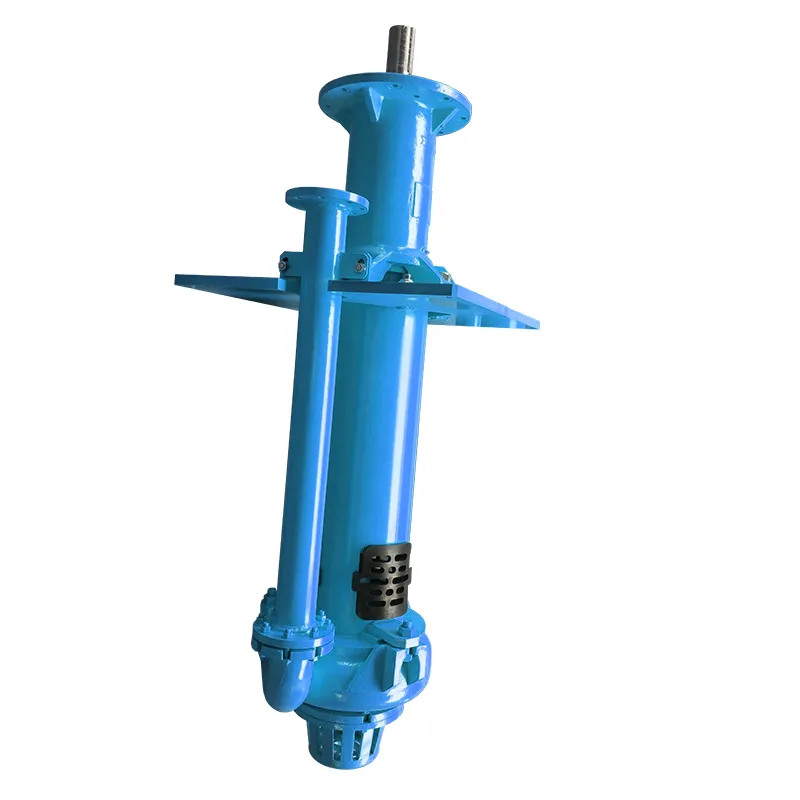

slurry pump factory

In the world of industrial applications, where efficiency, durability, and reliability are paramount, finding a trustworthy slurry pump factory can be a game changer. Slurry pumps play a critical role in various sectors, including mining, construction, and wastewater treatment. Selecting the right manufacturer is crucial to ensure not only the optimal performance but also the longevity of the pumps. This article delves into the essential factors to consider when choosing a slurry pump factory and how they contribute to meeting the Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) criteria.

The significance of customization cannot be overstated in slurry pump manufacturing. A factory that excels in customization is capable of adapting to the unique demands of a project, whether it involves adjusting the pump's flow rate, changing its material makeup, or redesigning its structure for better discharge efficiency. Custom solutions are often necessary to cope with harsh operating environments. The ability to deliver bespoke solutions demonstrates the factory’s comprehensive understanding of diverse operational challenges and its commitment to supporting its clients' specific objectives. In recent years, sustainability has also become a crucial factor in assessing a manufacturer's credibility. Eco-friendly practices such as energy-efficient manufacturing processes, recyclable materials, and environmentally-responsible supply chain decisions reflect a company's commitment to sustainability. Customers increasingly value such practices as they align their operations with global sustainability goals, thereby selecting partners that uphold these values. Ultimately, the choice of a slurry pump factory goes beyond the immediate transaction; it involves selecting a long-term partner whose vision and expertise align with your operational and strategic goals. The best manufacturers not only meet current demands but also anticipate future needs, enabling industries to prepare for advancements and shifts in technology and regulations. By aligning with such forward-thinking partners, customers ensure that their operations remain at the cutting edge of efficiency and innovation. In conclusion, selecting a slurry pump factory requires a comprehensive evaluation of their experience, expertise, authoritativeness, and trustworthiness. These qualities assure clients that they are not just buying a product but investing in a partnership that promises enhanced productivity, reduced downtime, and extensive support in pursuing operational excellence. As industries continue to evolve, partnering with a factory that meets these E-E-A-T criteria will undoubtedly be a crucial asset in navigating both today's demands and tomorrow's challenges.

The significance of customization cannot be overstated in slurry pump manufacturing. A factory that excels in customization is capable of adapting to the unique demands of a project, whether it involves adjusting the pump's flow rate, changing its material makeup, or redesigning its structure for better discharge efficiency. Custom solutions are often necessary to cope with harsh operating environments. The ability to deliver bespoke solutions demonstrates the factory’s comprehensive understanding of diverse operational challenges and its commitment to supporting its clients' specific objectives. In recent years, sustainability has also become a crucial factor in assessing a manufacturer's credibility. Eco-friendly practices such as energy-efficient manufacturing processes, recyclable materials, and environmentally-responsible supply chain decisions reflect a company's commitment to sustainability. Customers increasingly value such practices as they align their operations with global sustainability goals, thereby selecting partners that uphold these values. Ultimately, the choice of a slurry pump factory goes beyond the immediate transaction; it involves selecting a long-term partner whose vision and expertise align with your operational and strategic goals. The best manufacturers not only meet current demands but also anticipate future needs, enabling industries to prepare for advancements and shifts in technology and regulations. By aligning with such forward-thinking partners, customers ensure that their operations remain at the cutting edge of efficiency and innovation. In conclusion, selecting a slurry pump factory requires a comprehensive evaluation of their experience, expertise, authoritativeness, and trustworthiness. These qualities assure clients that they are not just buying a product but investing in a partnership that promises enhanced productivity, reduced downtime, and extensive support in pursuing operational excellence. As industries continue to evolve, partnering with a factory that meets these E-E-A-T criteria will undoubtedly be a crucial asset in navigating both today's demands and tomorrow's challenges.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024