-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 15:40

Back to list

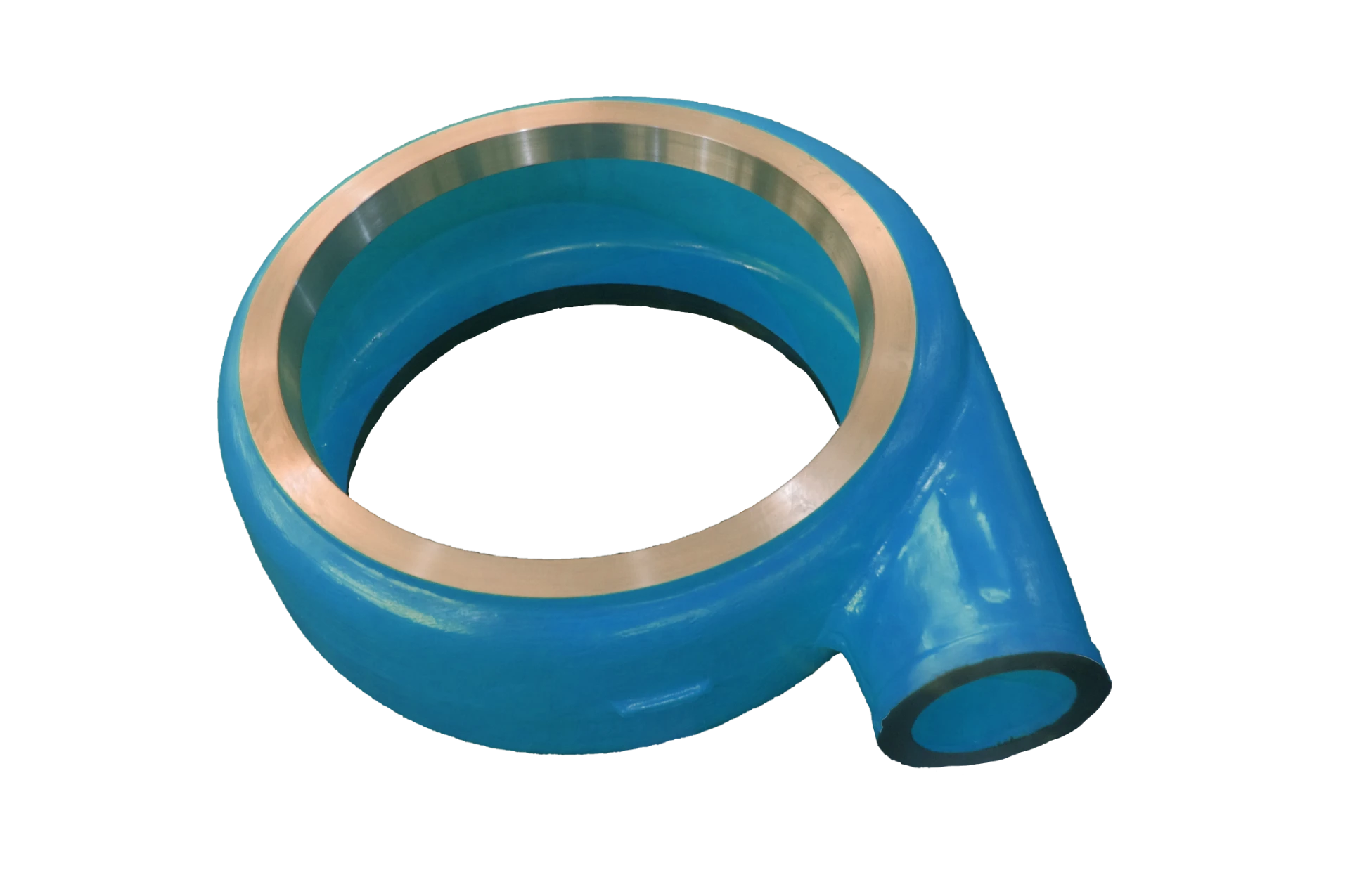

slurry pump closed impeller

In the realm of industrial fluid management, the slurry pump closed impeller stands as a pivotal innovation, offering a blend of efficiency and durability that is unmatched in its field. Leveraging extensive industry experience, it's apparent that closed impellers in slurry pumps provide enhanced operational benefits over their open and semi-open counterparts.

Trustworthiness in a product category like slurry pumps is paramount, given the critical role they play in continuous process operations. Users have reported that pumps equipped with closed impellers provide stable performance and predictable operational parameters. This reliability underpins trust in process outcomes and ensures safety and compliance in plant operations. Testimonials from long-term users highlight consistently high performance in extreme conditions, reinforcing their position as a preferred choice in hazardous applications. In conclusion, the slurry pump with a closed impeller design is more than just a component; it is a crucial investment in process efficiency, cost-effectiveness, and operational longevity. By balancing advanced engineering principles with practical experience from the field, it remains an authoritative choice for industries tackling the challenges of abrasive slurry handling.

Trustworthiness in a product category like slurry pumps is paramount, given the critical role they play in continuous process operations. Users have reported that pumps equipped with closed impellers provide stable performance and predictable operational parameters. This reliability underpins trust in process outcomes and ensures safety and compliance in plant operations. Testimonials from long-term users highlight consistently high performance in extreme conditions, reinforcing their position as a preferred choice in hazardous applications. In conclusion, the slurry pump with a closed impeller design is more than just a component; it is a crucial investment in process efficiency, cost-effectiveness, and operational longevity. By balancing advanced engineering principles with practical experience from the field, it remains an authoritative choice for industries tackling the challenges of abrasive slurry handling.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024