-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 06, 2025 03:55

Back to list

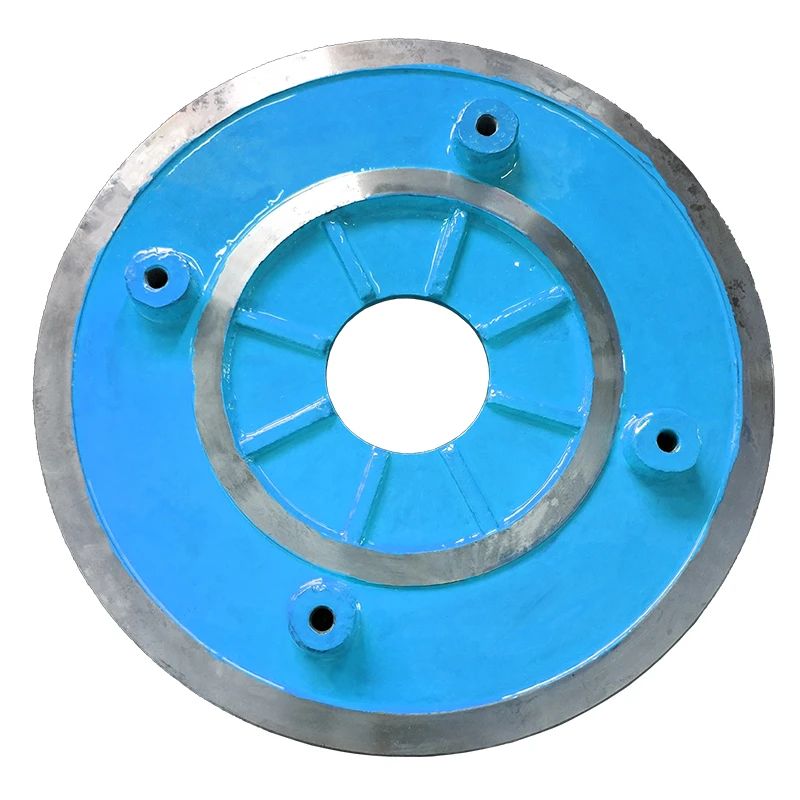

slurry pump casing

Understanding the intricacies of slurry pump casing is crucial for anyone involved in industries dealing with highly abrasive and corrosive fluids. This component is fundamental in protecting the pump's physical integrity while ensuring efficient operation. An expert analysis on slurry pump casing encompasses key factors like material composition, design considerations, and routine maintenance, which ultimately bolsters a website’s SEO by establishing authority and trustworthiness.

For website owners seeking to heighten their Google rankings, integrating detailed, experience-driven content about slurry pump casings achieves the dual purpose of serving both SEO advantages and providing authoritative knowledge to users. Embedding case studies where companies successfully enhance slurry pump performance through innovative casing choices can boost user engagement and trust. Another angle of authority stems from industry certifications and standards. Discussing compliance with international standards, such as ISO or ASTM specifications, assures users of the quality and reliability of the slurry pump casings being discussed. This attention to regulatory detail also signals trustworthiness to Google’s algorithms, reinforcing the site’s credibility. Furthermore, user-generated insights, such as expert interviews or customer testimonials about specific slurry pump casing experiences, can be invaluable. These narratives craft a compelling story around the product's real-world applications, reinforcing the site's authoritative stance and enriching its content strategy. In the digital age, Google rewards content that offers substantial value through precise expertise, authoritativeness, and trustworthiness. Crafting an enlightened narrative about slurry pump casing, backed by technical insights and real-world applications, not only satisfies these E-A-T criteria but also solidifies the site’s position as a leading resource in industrial pumping technology.

For website owners seeking to heighten their Google rankings, integrating detailed, experience-driven content about slurry pump casings achieves the dual purpose of serving both SEO advantages and providing authoritative knowledge to users. Embedding case studies where companies successfully enhance slurry pump performance through innovative casing choices can boost user engagement and trust. Another angle of authority stems from industry certifications and standards. Discussing compliance with international standards, such as ISO or ASTM specifications, assures users of the quality and reliability of the slurry pump casings being discussed. This attention to regulatory detail also signals trustworthiness to Google’s algorithms, reinforcing the site’s credibility. Furthermore, user-generated insights, such as expert interviews or customer testimonials about specific slurry pump casing experiences, can be invaluable. These narratives craft a compelling story around the product's real-world applications, reinforcing the site's authoritative stance and enriching its content strategy. In the digital age, Google rewards content that offers substantial value through precise expertise, authoritativeness, and trustworthiness. Crafting an enlightened narrative about slurry pump casing, backed by technical insights and real-world applications, not only satisfies these E-A-T criteria but also solidifies the site’s position as a leading resource in industrial pumping technology.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024