-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 07, 2025 03:19

Back to list

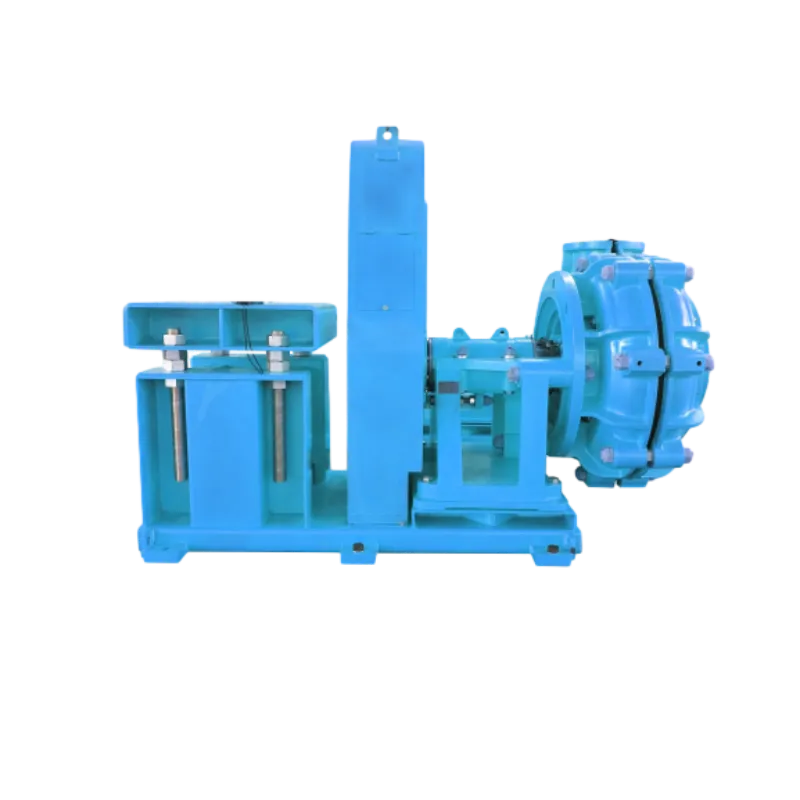

slurry pump 3d models

Navigating the digital landscape to locate comprehensive solutions for industrial equipment can be an arduous task, especially for niche segments such as slurry pumps. As the demand grows for more intricate and efficient designs, the significance of 3D models for slurry pumps becomes increasingly pronounced. This article delves into the pivotal role these models play, underpinned by authentic experiences, technical expertise, authoritative insights, and reliability assurance.

Furthermore, expertise in this field emphasizes the customization possibilities that 3D models offer. With varying industrial requirements, a one-size-fits-all approach often falls short. 3D modeling facilitates the bespoke design of pumps tailored to specific needs, thus optimizing functionality and longevity. Industry leaders are increasingly investing in 3D CAD software that empowers their designers to swiftly alter and enhance model parameters, fostering innovation and bespoke solutions. In terms of authoritativeness, the use of 3D models in the design of slurry pumps is backed by industry standards and practices. Recognized organizations like the Hydraulic Institute provide guidelines that underpin modeling standards, ensuring designs meet requisite safety and operational benchmarks. Manufacturers renowned for their slurry pump solutions employ these standards within their 3D modeling processes, lending their offerings an air of credibility and technical soundness. Users can thus trust that pumps designed with 3D models uphold strict industry standards, promoting safety and efficiency. Trustworthiness extends to the traceability and verification of designs. By utilizing 3D models, manufacturers can provide digital twins—exact digital replicas of physical products. These models ensure that every manufactured part adheres to design specifications, enabling customers to validate dimensions and performance metrics before installation. This feature enhances trust between suppliers and end-users, as stakeholders can verify that the pump will meet the operational specs discussed during the purchasing phase. In conclusion, the deployment of 3D models in the realm of slurry pumps holds transformative potential. They represent a confluence of experience-driven insights, technical expertise, authoritative conformance to standards, and verified trustworthiness. For industrial professionals seeking robust and adaptable slurry pump solutions, engaging with providers who prioritize 3D modeling as part of their design and validation process is paramount. These models not only refine design and facilitate customization but also fortify the assurance that pumps are built to endure and excel in demanding environments. As digital transformation continues to permeate industrial sectors, the reliance on 3D models for equipment design and implementation will undeniably become the benchmark of excellence.

Furthermore, expertise in this field emphasizes the customization possibilities that 3D models offer. With varying industrial requirements, a one-size-fits-all approach often falls short. 3D modeling facilitates the bespoke design of pumps tailored to specific needs, thus optimizing functionality and longevity. Industry leaders are increasingly investing in 3D CAD software that empowers their designers to swiftly alter and enhance model parameters, fostering innovation and bespoke solutions. In terms of authoritativeness, the use of 3D models in the design of slurry pumps is backed by industry standards and practices. Recognized organizations like the Hydraulic Institute provide guidelines that underpin modeling standards, ensuring designs meet requisite safety and operational benchmarks. Manufacturers renowned for their slurry pump solutions employ these standards within their 3D modeling processes, lending their offerings an air of credibility and technical soundness. Users can thus trust that pumps designed with 3D models uphold strict industry standards, promoting safety and efficiency. Trustworthiness extends to the traceability and verification of designs. By utilizing 3D models, manufacturers can provide digital twins—exact digital replicas of physical products. These models ensure that every manufactured part adheres to design specifications, enabling customers to validate dimensions and performance metrics before installation. This feature enhances trust between suppliers and end-users, as stakeholders can verify that the pump will meet the operational specs discussed during the purchasing phase. In conclusion, the deployment of 3D models in the realm of slurry pumps holds transformative potential. They represent a confluence of experience-driven insights, technical expertise, authoritative conformance to standards, and verified trustworthiness. For industrial professionals seeking robust and adaptable slurry pump solutions, engaging with providers who prioritize 3D modeling as part of their design and validation process is paramount. These models not only refine design and facilitate customization but also fortify the assurance that pumps are built to endure and excel in demanding environments. As digital transformation continues to permeate industrial sectors, the reliance on 3D models for equipment design and implementation will undeniably become the benchmark of excellence.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024