-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 01:12

Back to list

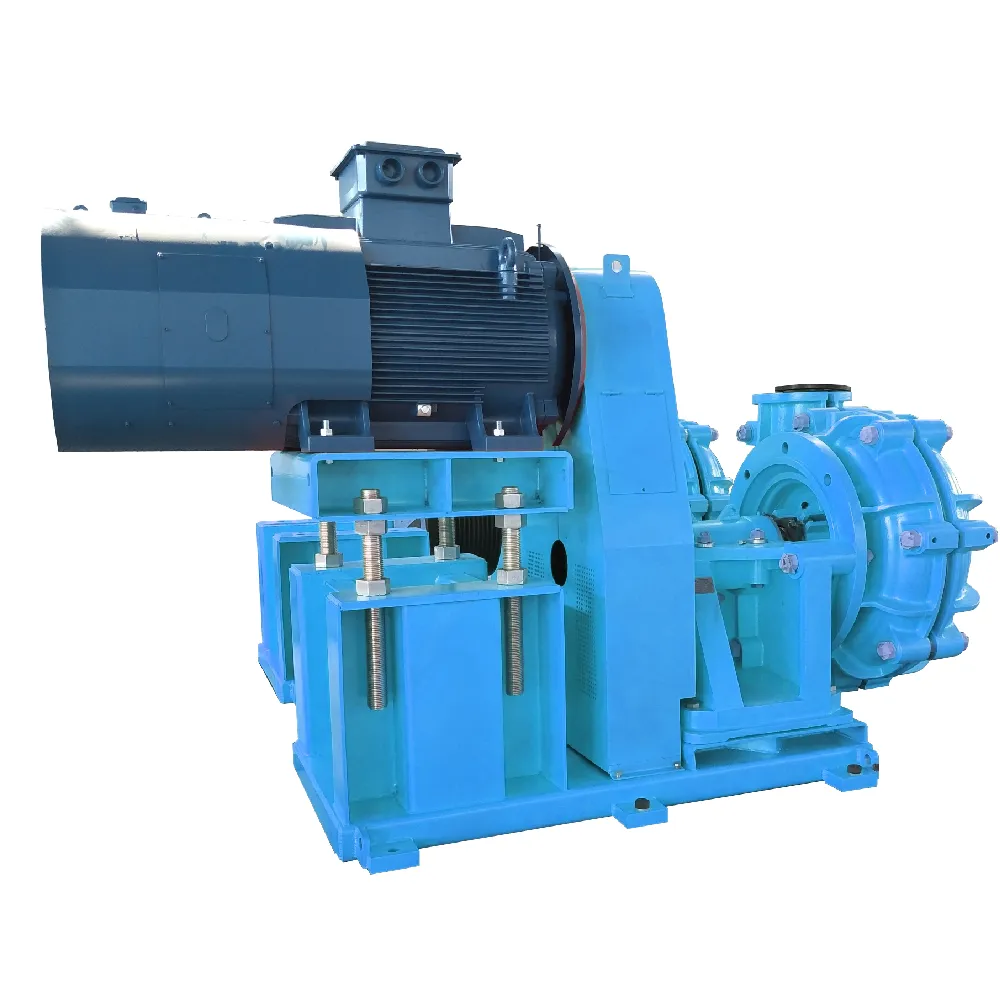

slurry mixing pump

Slurry mixing pumps play a crucial role in various industrial and construction applications. These specialized pumps are designed to handle thick, viscous mixtures of liquids and solids, ensuring efficient transport and processing across different sectors. With the right pump, operations can achieve optimal efficiency, reducing both time and cost in projects.

Trustworthiness is cultivated through transparent communication and post-purchase support from manufacturers. Responsive customer service that offers technical guidance whenever needed is vital. Brands that provide comprehensive warranties and readily available replacement parts instill confidence, as these measures indicate a commitment to customer satisfaction. Additionally, providing detailed user manuals and training materials helps operators effectively manage and maintain their pumps, fostering a sense of trust. In construction environments, where time is often of the essence, slurry mixing pumps can dramatically shorten project timelines. They achieve this by reliably handling bulk materials such as cement or bentonite slurries, integral to foundational work. A dependable slurry pump ensures these materials are mixed and delivered consistently, supporting robust building practices and minimizing costly rework. In mining applications, slurry pumps are indispensable for processing mineral concentrates, which often involve abrasive slurries containing rocks and sands. Here, high-efficiency pumps with replaceable liners and impellers are crucial to withstand the rigorous demands. By optimizing energy use and reducing wear, these pumps also contribute to lowering the environmental footprint of mining operations. Looking towards the future, sustainability in pump technology continues to gain traction. Manufacturers are increasingly focusing on producing eco-friendly pumps that reduce carbon emissions and energy consumption. Innovations such as solar-powered pumps or those engineered to recycle water within systems exemplify ongoing advancements prioritizing environmental responsibility. In summary, selecting the right slurry mixing pump requires a detailed understanding of the specific needs of your operation, alongside a consideration for the pump’s material construction, technological features, and the support provided by the manufacturer. Leveraging the latest advancements in pump technology ensures that industries can enhance their processing capabilities, achieve superior efficiency, and maintain sustainable practices.

Trustworthiness is cultivated through transparent communication and post-purchase support from manufacturers. Responsive customer service that offers technical guidance whenever needed is vital. Brands that provide comprehensive warranties and readily available replacement parts instill confidence, as these measures indicate a commitment to customer satisfaction. Additionally, providing detailed user manuals and training materials helps operators effectively manage and maintain their pumps, fostering a sense of trust. In construction environments, where time is often of the essence, slurry mixing pumps can dramatically shorten project timelines. They achieve this by reliably handling bulk materials such as cement or bentonite slurries, integral to foundational work. A dependable slurry pump ensures these materials are mixed and delivered consistently, supporting robust building practices and minimizing costly rework. In mining applications, slurry pumps are indispensable for processing mineral concentrates, which often involve abrasive slurries containing rocks and sands. Here, high-efficiency pumps with replaceable liners and impellers are crucial to withstand the rigorous demands. By optimizing energy use and reducing wear, these pumps also contribute to lowering the environmental footprint of mining operations. Looking towards the future, sustainability in pump technology continues to gain traction. Manufacturers are increasingly focusing on producing eco-friendly pumps that reduce carbon emissions and energy consumption. Innovations such as solar-powered pumps or those engineered to recycle water within systems exemplify ongoing advancements prioritizing environmental responsibility. In summary, selecting the right slurry mixing pump requires a detailed understanding of the specific needs of your operation, alongside a consideration for the pump’s material construction, technological features, and the support provided by the manufacturer. Leveraging the latest advancements in pump technology ensures that industries can enhance their processing capabilities, achieve superior efficiency, and maintain sustainable practices.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024