-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 11:57

Back to list

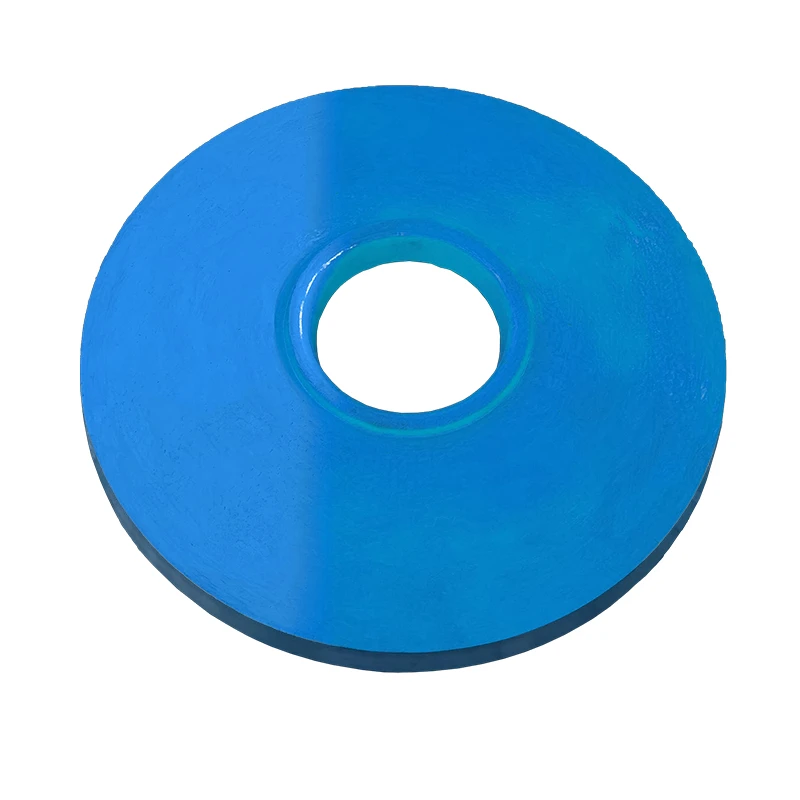

Pump Wear Parts Mmframe Plate Submersible Pump Flow Parts

Slurry dewatering pumps are pivotal in industries where solid-liquid separation is paramount. In mining, construction, wastewater treatment, and various industrial applications, the need to efficiently separate slurry components is crucial. Selecting the right slurry dewatering pump requires understanding the slurry's characteristics and the operational environment. This guide sheds light on the essential aspects to consider when choosing these pumps to ensure optimal performance and longevity.

Real-world experience further underlines the importance of maintaining a robust maintenance strategy to preserve pump integrity and functionality. Regular inspections, routine maintenance schedules, and using genuine spare parts are practices critical to sustaining long-term pump performance. Operational logs can be invaluable, providing data that help predict maintenance needs and avoid unexpected downtime. Investing in these pumps also requires a focus on sustainability and environmental considerations. Advances in pump design now incorporate features that improve energy efficiency, reduce noise levels, and minimize environmental impact. Selecting energy-efficient models not only helps in reducing operational costs but also supports corporate sustainability objectives, aligning with global environmental standards. When considering brand authority, leading manufacturers are recognized for their innovation and the ability to tailor products to specific industrial needs. They invest significantly in research and development, continually advancing pump technology to address emergent challenges in slurry dewatering. This commitment to improvement not only enhances the performance and efficiency of pump solutions but also fortifies their position as trusted partners in industrial operations. Building credibility in the slurry pump market involves manufacturers offering comprehensive technical support and customer service. Accessible technical support ensures that clients can promptly address any issues, optimize pump use, and extend the lifespan of the equipment. Faced with varied slurry compositions and operating conditions, users benefit from ongoing dialogue with manufacturers, ensuring that pump solutions evolve alongside industrial needs. In conclusion, slurry dewatering pumps are integral to efficient slurry handling across various industries. Their design, operational expertise, and sustainable practices are pivotal in maintaining productivity and reducing costs. By emphasizing advanced technology, reliable performance, and tailored solutions, these pumps stand as critical components in industrial operations, supporting both economic and environmental objectives. Through informed selection and strategic maintenance, slurry dewatering pumps not only enhance operational efficiency but also reinforce the resilience and adaptability of industrial systems, fostering a progressive and sustainable industrial landscape.

Real-world experience further underlines the importance of maintaining a robust maintenance strategy to preserve pump integrity and functionality. Regular inspections, routine maintenance schedules, and using genuine spare parts are practices critical to sustaining long-term pump performance. Operational logs can be invaluable, providing data that help predict maintenance needs and avoid unexpected downtime. Investing in these pumps also requires a focus on sustainability and environmental considerations. Advances in pump design now incorporate features that improve energy efficiency, reduce noise levels, and minimize environmental impact. Selecting energy-efficient models not only helps in reducing operational costs but also supports corporate sustainability objectives, aligning with global environmental standards. When considering brand authority, leading manufacturers are recognized for their innovation and the ability to tailor products to specific industrial needs. They invest significantly in research and development, continually advancing pump technology to address emergent challenges in slurry dewatering. This commitment to improvement not only enhances the performance and efficiency of pump solutions but also fortifies their position as trusted partners in industrial operations. Building credibility in the slurry pump market involves manufacturers offering comprehensive technical support and customer service. Accessible technical support ensures that clients can promptly address any issues, optimize pump use, and extend the lifespan of the equipment. Faced with varied slurry compositions and operating conditions, users benefit from ongoing dialogue with manufacturers, ensuring that pump solutions evolve alongside industrial needs. In conclusion, slurry dewatering pumps are integral to efficient slurry handling across various industries. Their design, operational expertise, and sustainable practices are pivotal in maintaining productivity and reducing costs. By emphasizing advanced technology, reliable performance, and tailored solutions, these pumps stand as critical components in industrial operations, supporting both economic and environmental objectives. Through informed selection and strategic maintenance, slurry dewatering pumps not only enhance operational efficiency but also reinforce the resilience and adaptability of industrial systems, fostering a progressive and sustainable industrial landscape.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024