-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 11:12

Back to list

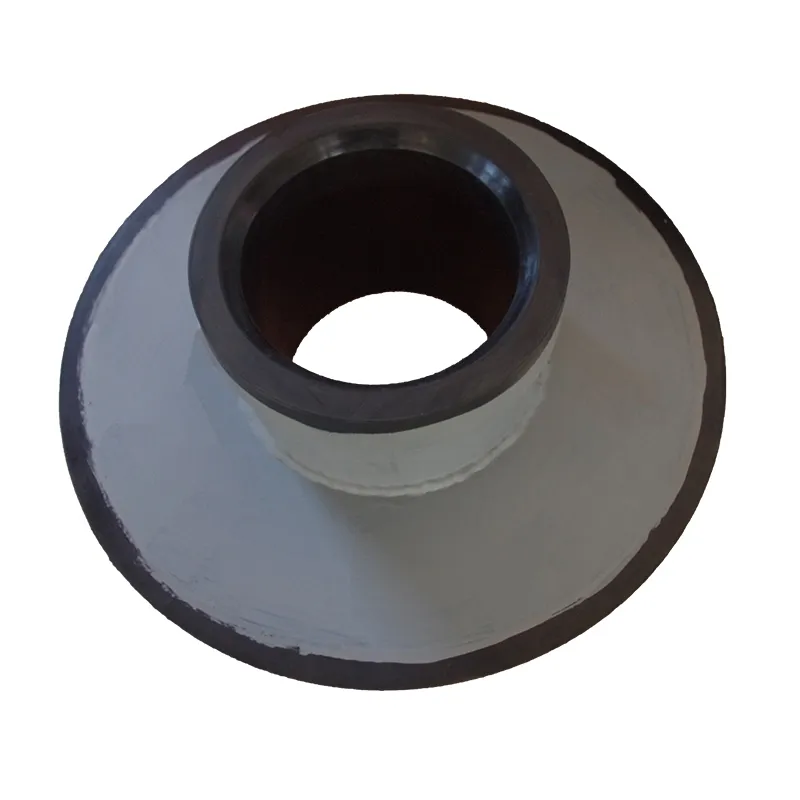

Pump Wear Parts SPR65206 Rubber

Enhancing industrial processes often hinges on the seamless operation of equipment designed to handle challenging materials. The slurry booster pump stands as a pivotal element in systems where the efficient transportation of slurry—a mixture of solid particles suspended in liquid—is critical.

Companies experienced in deploying pipeline transport systems understand the necessity of correctly positioning slurry booster pumps. Strategic placement along the pipeline counteracts gravitational and frictional losses, particularly over extended distances. Moreover, integrating sensors and monitoring systems within the pump offers real-time feedback, aiding in proactive maintenance and system troubleshooting. The authority of a manufacturer can often be evaluated based on their track record and client testimonials. Industry certifications, such as ISO standards for quality management, further reinforce a company's commitment to delivering pumps that meet rigorous operational demands. Collaboration with reputable manufacturers ensures access to technical support and expert advice, fostering trust and reliability in the ongoing use of their slurry booster pumps. Trustworthiness in slurry booster pump operations is principally guided by stringent safety protocols. Designed to withstand harsh environments, these pumps are tested under extreme conditions to guarantee safety. Regularly scheduled assessments and adherence to operational guidelines underscore the importance of safety, protecting both personnel and equipment. Understanding slurry booster pumps is not merely about technical specifications but insight into how these devices integrate within broader industrial frameworks. A holistic approach involves not only selecting the right pump but also cultivating relationships with knowledgeable manufacturers and field experts. Sharing experiences and solutions within industry forums can further enhance understanding and collective problem-solving capabilities among professionals. For those invested in industries where the management of slurry is fundamental, the decision to employ a slurry booster pump should align with overarching business goals of efficiency, sustainability, and reliability. When correctly optimized, these pumps transform challenging mixtures into manageable streams, fueling industrial success and innovation.

Companies experienced in deploying pipeline transport systems understand the necessity of correctly positioning slurry booster pumps. Strategic placement along the pipeline counteracts gravitational and frictional losses, particularly over extended distances. Moreover, integrating sensors and monitoring systems within the pump offers real-time feedback, aiding in proactive maintenance and system troubleshooting. The authority of a manufacturer can often be evaluated based on their track record and client testimonials. Industry certifications, such as ISO standards for quality management, further reinforce a company's commitment to delivering pumps that meet rigorous operational demands. Collaboration with reputable manufacturers ensures access to technical support and expert advice, fostering trust and reliability in the ongoing use of their slurry booster pumps. Trustworthiness in slurry booster pump operations is principally guided by stringent safety protocols. Designed to withstand harsh environments, these pumps are tested under extreme conditions to guarantee safety. Regularly scheduled assessments and adherence to operational guidelines underscore the importance of safety, protecting both personnel and equipment. Understanding slurry booster pumps is not merely about technical specifications but insight into how these devices integrate within broader industrial frameworks. A holistic approach involves not only selecting the right pump but also cultivating relationships with knowledgeable manufacturers and field experts. Sharing experiences and solutions within industry forums can further enhance understanding and collective problem-solving capabilities among professionals. For those invested in industries where the management of slurry is fundamental, the decision to employ a slurry booster pump should align with overarching business goals of efficiency, sustainability, and reliability. When correctly optimized, these pumps transform challenging mixtures into manageable streams, fueling industrial success and innovation.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024