-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 20, 2025 02:20

Back to list

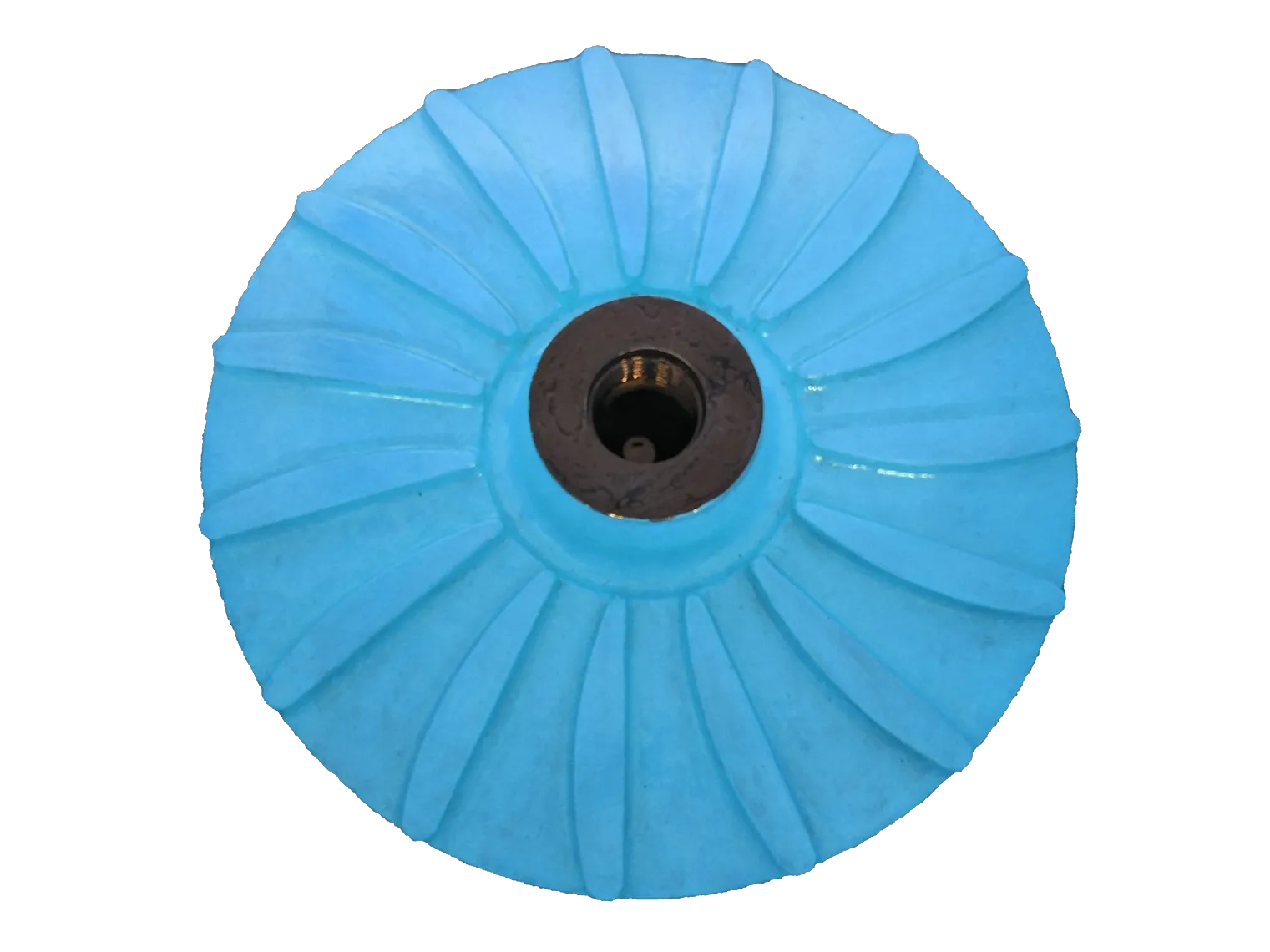

slurry agitator

Slurry agitators are pivotal components in various industries like wastewater treatment, mining, and agriculture. These devices ensure the homogeneity of suspended particles in liquids, which enhances the efficiency of numerous processes. Understanding their operation, maintenance, and potential issues helps businesses maximize productivity and minimize downtime.

Another key consideration is energy efficiency. Slurry agitators are often large power consumers, and inefficient operation can significantly increase energy costs. Therefore, selecting units with variable speed drives allows for adjusting the agitation intensity according to the current process demands, conserving energy, and reducing operational costs. Products with embedded smart technology that offer real-time monitoring and predictive maintenance alerts can further enhance efficiency and reliability. Smart agitators track performance metrics and slurry conditions, alerting operators to potential issues before they escalate into significant problems, thereby preventing unscheduled downtimes. Adopting best industry practices and adhering to manufacturers' recommendations also increase the effectiveness and reliability of slurry agitators. Consulting with experienced professionals during the selection and installation phases can optimize system performance to meet specific operational demands efficiently. The need for innovation in slurry agitators is ever-present, driven by the demand for improved reliability, efficiency, and adaptability across various industries. Companies are constantly investing in research and development to create more advanced models that meet the evolving demands of complex industrial processes. In conclusion, slurry agitators are indispensable in ensuring that various industrial operations run smoothly and efficiently. By concentrating on selecting the right agitator type, focusing on proper maintenance, and considering innovative technological advancements, industries can greatly enhance their operational efficiencies while ensuring the longevity of their equipment. Investing in high-quality slurry agitators pays off by saving costs through efficient operation and minimizing downtime, making it a strategic priority for any business involved in slurry processing.

Another key consideration is energy efficiency. Slurry agitators are often large power consumers, and inefficient operation can significantly increase energy costs. Therefore, selecting units with variable speed drives allows for adjusting the agitation intensity according to the current process demands, conserving energy, and reducing operational costs. Products with embedded smart technology that offer real-time monitoring and predictive maintenance alerts can further enhance efficiency and reliability. Smart agitators track performance metrics and slurry conditions, alerting operators to potential issues before they escalate into significant problems, thereby preventing unscheduled downtimes. Adopting best industry practices and adhering to manufacturers' recommendations also increase the effectiveness and reliability of slurry agitators. Consulting with experienced professionals during the selection and installation phases can optimize system performance to meet specific operational demands efficiently. The need for innovation in slurry agitators is ever-present, driven by the demand for improved reliability, efficiency, and adaptability across various industries. Companies are constantly investing in research and development to create more advanced models that meet the evolving demands of complex industrial processes. In conclusion, slurry agitators are indispensable in ensuring that various industrial operations run smoothly and efficiently. By concentrating on selecting the right agitator type, focusing on proper maintenance, and considering innovative technological advancements, industries can greatly enhance their operational efficiencies while ensuring the longevity of their equipment. Investing in high-quality slurry agitators pays off by saving costs through efficient operation and minimizing downtime, making it a strategic priority for any business involved in slurry processing.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024