-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 17, 2025 20:34

Back to list

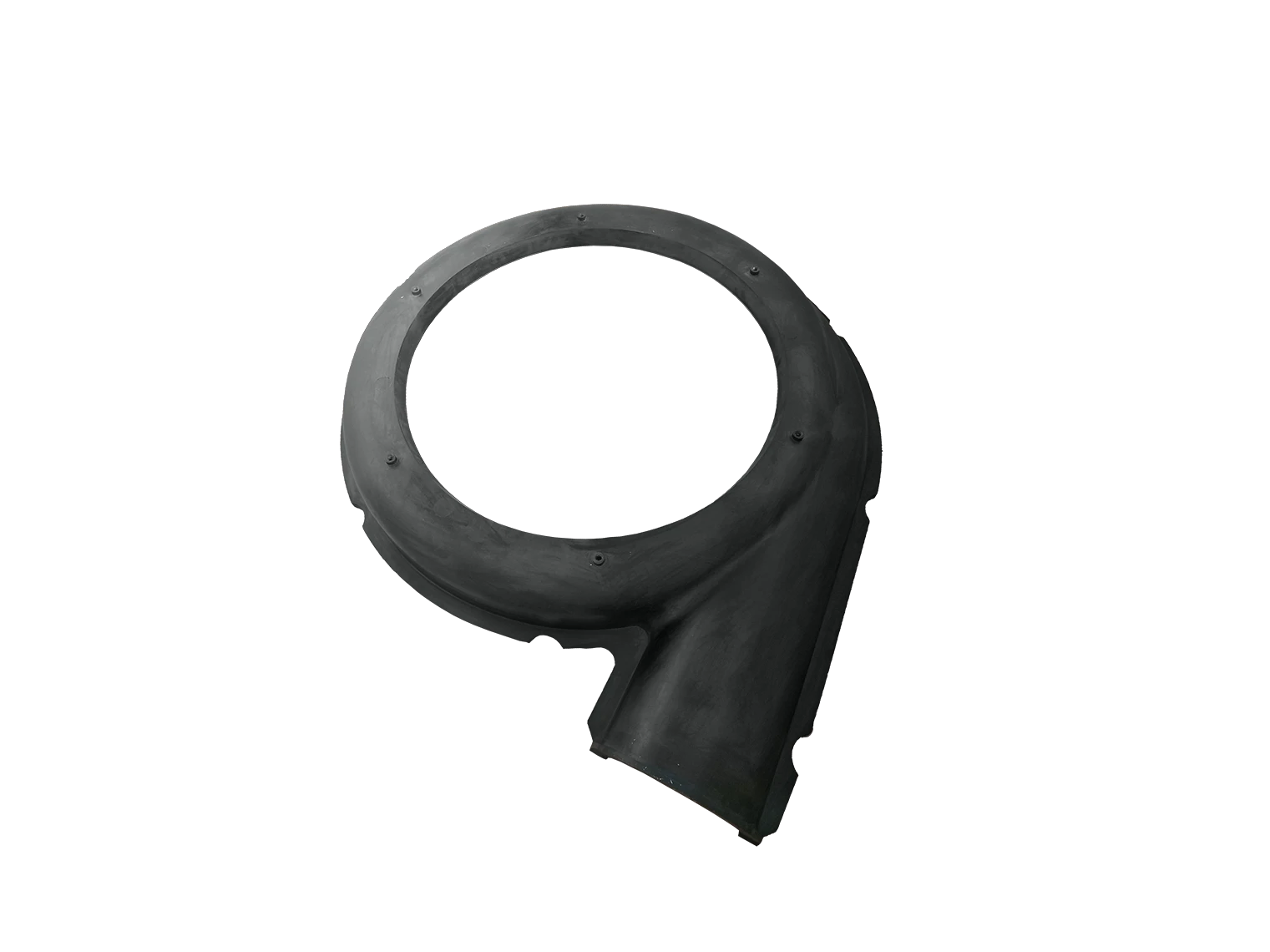

sludge pump

The operational dynamics of industries dealing with viscous, challenging materials heavily rely on specialized equipment, with the sludge pump being an inevitable key player. This integral component stands at the forefront of managing the muddy, sludgy challenges that many sectors, including wastewater treatment and mining, encounter daily.

Expertise in handling sludge pump operations is not only about selecting the right pump but also includes strategic maintenance practices. Regular maintenance routines, including the frequent inspection of wear-prone components such as impellers and casing, significantly enhance the pump's lifespan and performance. Implementing a preventive maintenance schedule can curtail unexpected downtimes, ensuring operational efficiency and reliability, which are critical in industries with demanding schedules. Authoritativeness on sludge pumps is demonstrated through the expertise of original equipment manufacturers (OEMs) who provide cutting-edge solutions tailored for evolving industrial challenges. Leading manufacturers routinely engage with industry experts to innovate and refine pump designs, ensuring contemporary demands are met with superior technology and materials. Investing in equipment from reputable manufacturers guarantees access to advanced features like automated control systems, which significantly enhance the safety and operational efficiency of sludge pump operations. Trustworthiness in the realm of sludge pump functionality and procurement is bolstered by impartial reviews and performance evaluations. Industry forums and case studies often serve as valuable resources for new industry entrants, providing insights from seasoned professionals who have rigorously tested various models under real-world conditions. Establishing relationships with trusted vendors who offer after-sales support and service contracts further secures the trust necessary for industries heavily dependent on uninterrupted pump operations. Incorporating these elements into a company's operational strategy not only ensures optimal pump performance but also contributes to broader business goals. Sludge pumps, though just a component of the larger operational framework, play a pivotal role in achieving efficiency and durability in environments fraught with challenges. As industries continue to evolve and face new obstacles, the sludge pump remains a critical asset, driving productivity and operational excellence with its unmatched capability to handle the toughest tasks.

Expertise in handling sludge pump operations is not only about selecting the right pump but also includes strategic maintenance practices. Regular maintenance routines, including the frequent inspection of wear-prone components such as impellers and casing, significantly enhance the pump's lifespan and performance. Implementing a preventive maintenance schedule can curtail unexpected downtimes, ensuring operational efficiency and reliability, which are critical in industries with demanding schedules. Authoritativeness on sludge pumps is demonstrated through the expertise of original equipment manufacturers (OEMs) who provide cutting-edge solutions tailored for evolving industrial challenges. Leading manufacturers routinely engage with industry experts to innovate and refine pump designs, ensuring contemporary demands are met with superior technology and materials. Investing in equipment from reputable manufacturers guarantees access to advanced features like automated control systems, which significantly enhance the safety and operational efficiency of sludge pump operations. Trustworthiness in the realm of sludge pump functionality and procurement is bolstered by impartial reviews and performance evaluations. Industry forums and case studies often serve as valuable resources for new industry entrants, providing insights from seasoned professionals who have rigorously tested various models under real-world conditions. Establishing relationships with trusted vendors who offer after-sales support and service contracts further secures the trust necessary for industries heavily dependent on uninterrupted pump operations. Incorporating these elements into a company's operational strategy not only ensures optimal pump performance but also contributes to broader business goals. Sludge pumps, though just a component of the larger operational framework, play a pivotal role in achieving efficiency and durability in environments fraught with challenges. As industries continue to evolve and face new obstacles, the sludge pump remains a critical asset, driving productivity and operational excellence with its unmatched capability to handle the toughest tasks.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024