-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 31, 2025 04:06

Back to list

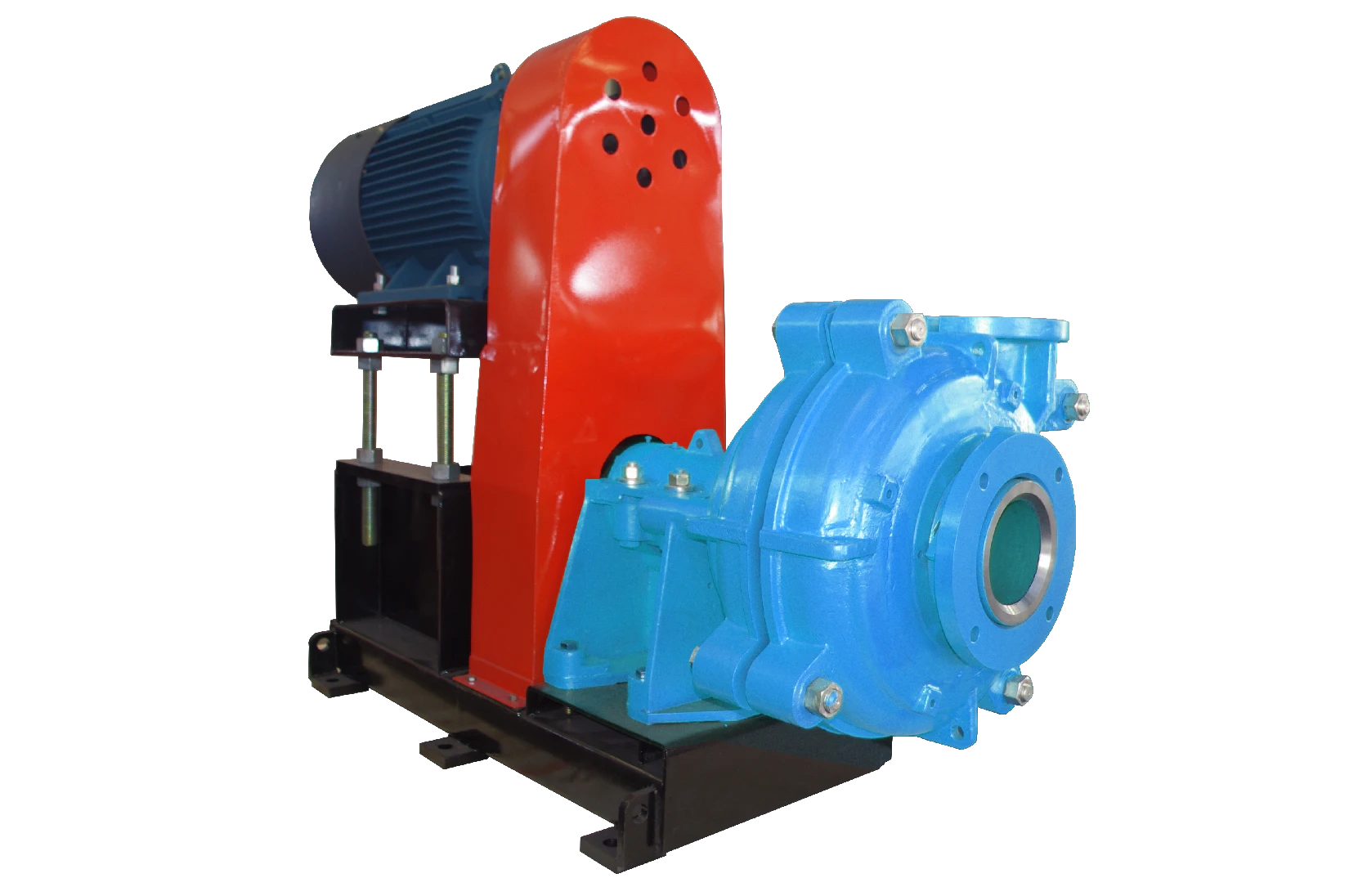

single stage vertical centrifugal pump

In the vast realm of fluid management, the single stage vertical centrifugal pump emerges as a paragon of efficiency and versatility, catering to a diverse range of industries worldwide. This specific type of pump is a staple in engineering solutions, renowned for its simplicity in design and effectiveness in operation. For industries that rely on the movement of fluids — be it water, chemicals, or other liquids — understanding the nuances of these pumps can significantly impact operational efficiency and overall productivity.

Authoritativeness in the realm of single stage vertical centrifugal pumps is underscored by their widespread endorsement by industry leaders and engineering experts. Manufacturers boast decades of research and development, producing units that align with stringent international standards. Certifications from recognized bodies such as ISO and API further cement their standing in fields demanding high reliability and performance. This authoritative backing gives procurement officers and engineers confidence in selecting these pumps for their projects, knowing they are opting for a historically proven and rigorously tested solution. Trustworthiness is crucial when selecting pumps that form the backbone of fluid management systems. The single stage vertical centrifugal pump's reputation for consistent performance and durability builds trust among its users. Case studies across sectors, including municipal water facilities and petrochemical companies, show a clear pattern of satisfaction, highlighting successful long-term deployment and the accompanying operational acclaim. Testimonials from seasoned engineers often emphasize the pumps' robustness under prolonged usage, reinforcing their reliability across diverse applications. For businesses considering this pump type, understanding the synergy between the pump's capabilities and their specific operational needs is essential. Consulting with experts who have an in-depth understanding of the application's requirements and the pump's specifications ensures optimal performance. Doing so not only maximizes the pump’s operational efficiency but also extends its lifespan, providing an exceptional return on investment. In conclusion, the single stage vertical centrifugal pump is a quintessential component for myriad industrial applications. Its design ingenuity, backed by authoritative validation and proven trustworthiness, positions it as a preferred choice for companies seeking to enhance their fluid handling systems. Whether you're in water management, chemical processing, or industrial manufacturing, integrating these pumps into your operation promises enhanced efficiency, reliability, and peace of mind.

Authoritativeness in the realm of single stage vertical centrifugal pumps is underscored by their widespread endorsement by industry leaders and engineering experts. Manufacturers boast decades of research and development, producing units that align with stringent international standards. Certifications from recognized bodies such as ISO and API further cement their standing in fields demanding high reliability and performance. This authoritative backing gives procurement officers and engineers confidence in selecting these pumps for their projects, knowing they are opting for a historically proven and rigorously tested solution. Trustworthiness is crucial when selecting pumps that form the backbone of fluid management systems. The single stage vertical centrifugal pump's reputation for consistent performance and durability builds trust among its users. Case studies across sectors, including municipal water facilities and petrochemical companies, show a clear pattern of satisfaction, highlighting successful long-term deployment and the accompanying operational acclaim. Testimonials from seasoned engineers often emphasize the pumps' robustness under prolonged usage, reinforcing their reliability across diverse applications. For businesses considering this pump type, understanding the synergy between the pump's capabilities and their specific operational needs is essential. Consulting with experts who have an in-depth understanding of the application's requirements and the pump's specifications ensures optimal performance. Doing so not only maximizes the pump’s operational efficiency but also extends its lifespan, providing an exceptional return on investment. In conclusion, the single stage vertical centrifugal pump is a quintessential component for myriad industrial applications. Its design ingenuity, backed by authoritative validation and proven trustworthiness, positions it as a preferred choice for companies seeking to enhance their fluid handling systems. Whether you're in water management, chemical processing, or industrial manufacturing, integrating these pumps into your operation promises enhanced efficiency, reliability, and peace of mind.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024