-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

self priming slurry pumps

Self-Priming Slurry Pumps An Essential Component in Industrial Fluid Management

In various industries, the efficient transfer of slurry—a mixture of solids and liquids—plays a crucial role in operations ranging from mining and construction to wastewater treatment. Among the solutions available for this specific task, self-priming slurry pumps stand out due to their unique design and capabilities. This article delves into what self-priming slurry pumps are, how they work, and their advantages in industrial applications.

Understanding Self-Priming Slurry Pumps

Self-priming slurry pumps are designed to handle tough abrasive slurries with high solid content effectively. Unlike regular pumps, these self-priming variants can remove air from the suction line and create a vacuum, allowing them to draw liquid from a lower level without the need for an external priming source. This feature is particularly beneficial in applications where the liquid source may be located below the pump or where there can be interruptions in flow.

Operating Principles

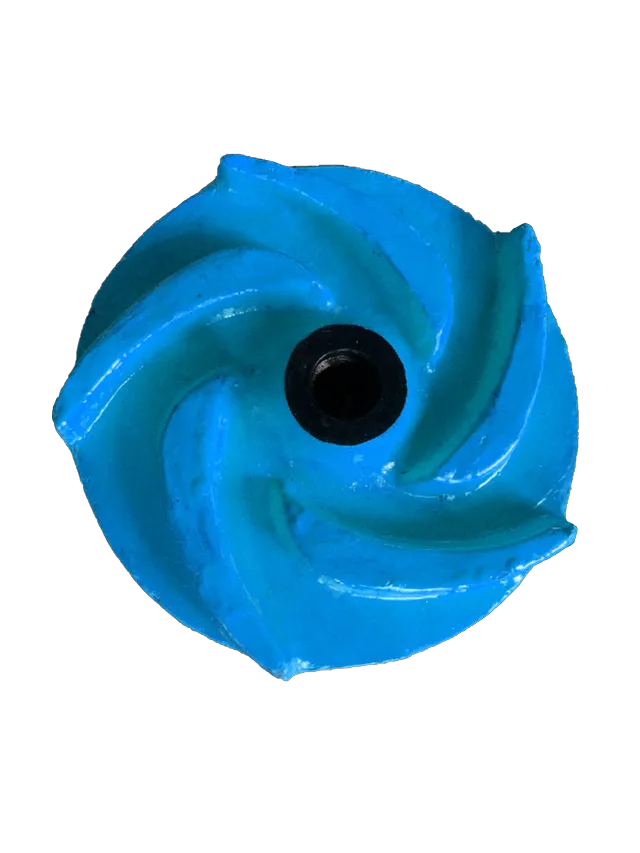

The operation of a self-priming slurry pump is remarkably efficient. At the heart of its functionality is a unique chamber design that facilitates the priming process. When the pump starts, it initially fills the priming chamber with liquid. As the impeller spins, it generates a centrifugal force that helps to discharge the air trapped in the pump and suction line. This action not only establishes a hydraulic seal but also allows the pump to lift the liquid from the source. Once the pump is primed, it can continue to operate without interruption, even if the liquid level fluctuates.

Key Advantages

1. Simplicity and Reduced Maintenance Self-priming pumps require less maintenance compared to traditional pumps, as they eliminate the need for complex priming setups. This simplicity translates to lower operational costs and reduced downtime.

self priming slurry pumps

2. Versatility These pumps can handle a wide variety of materials, including highly abrasive slurries with solids of different sizes. This versatility makes them ideal for industries such as mining, dredging, and environmental remediation.

3. Operational Efficiency Self-priming slurry pumps can quickly restore prime without manual intervention, enabling continuous operation. This efficiency is particularly advantageous in processes where slurry handling is constant or needs to be adjusted rapidly.

4. Reduced Footprint Since they can self-prime, these pumps can be mounted in various configurations and locations, reducing the need for extensive piping systems that are often necessary with traditional pumps.

5. Enhanced Safety By reducing the risk of air locks and cavitation, self-priming slurry pumps enhance safety in operations. This reliability ensures that workers are not exposed to the hazards associated with air-filled pump systems.

Applications in Industry

Self-priming slurry pumps find application across various sectors due to their robust performance. In mining operations, they are used to transport tailings and slurries that usually contain a mix of water, sand, and minerals. In the construction industry, they facilitate the movement of bentonite slurry used in drilling. Wastewater treatment facilities utilize these pumps to handle sludge effectively, ensuring that solid waste is transported to treatment areas without causing clogs or backups.

Conclusion

In conclusion, self-priming slurry pumps are an invaluable asset in the management of industrial fluids, offering a range of benefits that enhance efficiency, safety, and versatility in operations. Their ability to self-prime eliminates the need for cumbersome external priming systems, making them a cost-effective and reliable choice for companies dealing with challenging slurry applications. Whether it's in mining, construction, or wastewater management, these pumps prove their worth by enabling smoother, uninterrupted operations while minimizing maintenance requirements. As industries continue to evolve and demand robust solutions, self-priming slurry pumps will undoubtedly play a pivotal role in shaping the future of fluid management.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024