-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 09:38

Back to list

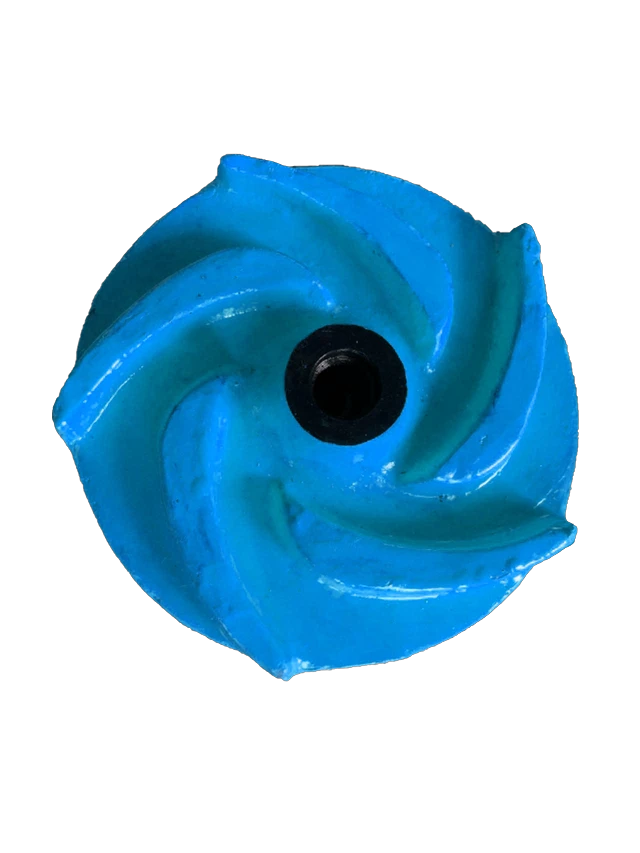

Vertical Slurry Pumps MM100RV-MTCD

Understanding the dynamics of modern industrial applications necessitates a focus on efficient and reliable equipment. Among these, the self-priming slurry pump stands out as an indispensable tool within industries handling abrasive and viscous fluids. This specialized pump offers solutions that enhance operational effectiveness, prevent downtime, and ensure fluid handling tasks are executed seamlessly.

Expertise in the optimum utilization of self-priming slurry pumps encompasses understanding their operation parameters and customizing solutions to specific industrial needs. Selecting an incorrectly sized pump can lead to inefficiencies, such as higher energy consumption or inadequate slurry transport. It is thus crucial for engineers and industrial operators to work collaboratively in assessing system requirements and ensuring the correct specifications are chosen to meet operational demands. Authoritativeness in the deployment of self-priming slurry pumps is vital. Manufacturers such as Sulzer, Weir Minerals, and Grundfos are renowned for their innovation and reliability in producing high-performance slurry pumps. Their products often come with guarantees backed by extensive research and development, ensuring trust and dependability in diverse working conditions. Assurance from such industry leaders facilitates peace of mind, knowing that the equipment involved is designed and backed by global experts. Trustworthiness in pump systems, particularly those dealing with complex media like slurries, is founded on performance consistency and service support. Reliable self-priming slurry pumps are not only consistently built to high standards but are also paired with robust after-sales service and support teams that can address any operational issues swiftly. Building rapport with a trusted supplier provides the added advantage of accessing expert insights and advanced troubleshooting solutions, further optimizing pump performance. In summary, the implementation of self-priming slurry pumps is instrumental in streamlining operations across industries dealing with abrasive and viscous media. Their self-priming capability, coupled with durable construction and expert manufacturer support, places them at the forefront of fluid handling solutions. For any industry reliant on efficient slurry transfer, investing in high-quality self-priming pumps is a strategic decision that promises enhanced productivity, reduced costs, and long-term operational sustainability.

Expertise in the optimum utilization of self-priming slurry pumps encompasses understanding their operation parameters and customizing solutions to specific industrial needs. Selecting an incorrectly sized pump can lead to inefficiencies, such as higher energy consumption or inadequate slurry transport. It is thus crucial for engineers and industrial operators to work collaboratively in assessing system requirements and ensuring the correct specifications are chosen to meet operational demands. Authoritativeness in the deployment of self-priming slurry pumps is vital. Manufacturers such as Sulzer, Weir Minerals, and Grundfos are renowned for their innovation and reliability in producing high-performance slurry pumps. Their products often come with guarantees backed by extensive research and development, ensuring trust and dependability in diverse working conditions. Assurance from such industry leaders facilitates peace of mind, knowing that the equipment involved is designed and backed by global experts. Trustworthiness in pump systems, particularly those dealing with complex media like slurries, is founded on performance consistency and service support. Reliable self-priming slurry pumps are not only consistently built to high standards but are also paired with robust after-sales service and support teams that can address any operational issues swiftly. Building rapport with a trusted supplier provides the added advantage of accessing expert insights and advanced troubleshooting solutions, further optimizing pump performance. In summary, the implementation of self-priming slurry pumps is instrumental in streamlining operations across industries dealing with abrasive and viscous media. Their self-priming capability, coupled with durable construction and expert manufacturer support, places them at the forefront of fluid handling solutions. For any industry reliant on efficient slurry transfer, investing in high-quality self-priming pumps is a strategic decision that promises enhanced productivity, reduced costs, and long-term operational sustainability.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024