-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 05, 2025 01:16

Back to list

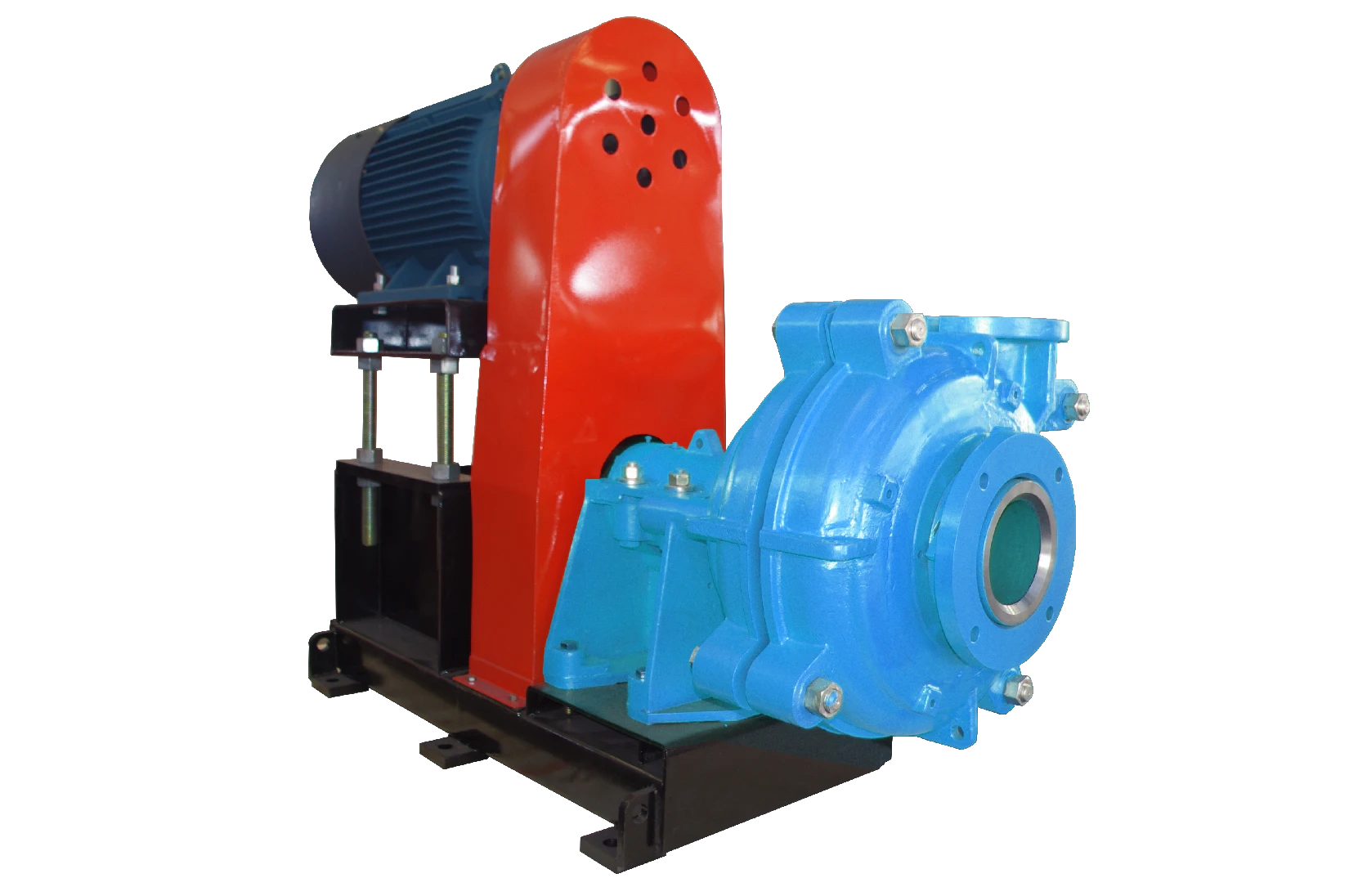

screw slurry pump

The screw slurry pump, an essential component in fluid handling processes, stands out for its robust capacity and reliability in managing abrasive, high-solid-content slurries. This type of pump, known for its specialized design, demonstrates unparalleled efficiency in various industrial applications, including mining, construction, and wastewater treatment.

An authoritative aspect of screw slurry pumps lies in their customization; manufacturers offer extensive options tailored to specific industrial needs. Options such as different rotor coatings and stator materials allow these pumps to be adapted for highly corrosive environments or to handle unique slurry compositions. These personalization capabilities not only enhance pump integrity but also extend their lifespan, assuring users of their investment. Trustworthiness in screw slurry pump systems is further underscored by their eco-friendly operations. Compared to traditional pumping methods, screw pumps have lower energy consumption, thanks to their ability to minimize friction losses. This energy efficiency doesn't just lower operational costs but also contributes to a reduced carbon footprint, aligning with growing environmental conservation efforts. Furthermore, screw slurry pumps are known for their quiet operation. The smooth flow generated by the helical design reduces noise pollution, an often-overlooked advantage that enhances workplace environments, ensuring compliance with occupational health standards and promoting worker safety and satisfaction. For industries looking for reliable, efficient, and cost-effective slurry handling solutions, the screw slurry pump stands out as the product of choice. With its established performance record, backed by extensive engineering know-how, this pump type not only meets but exceeds the ever-growing demands of modern industry sectors. Ultimately, investing in a screw slurry pump equates to a commitment to quality and efficiency, principles that are crucial to maintaining competitiveness in today's fast-evolving markets. Their enduring design and operational benefits make them an invaluable component of any organization looking to optimize their fluid handling processes.

An authoritative aspect of screw slurry pumps lies in their customization; manufacturers offer extensive options tailored to specific industrial needs. Options such as different rotor coatings and stator materials allow these pumps to be adapted for highly corrosive environments or to handle unique slurry compositions. These personalization capabilities not only enhance pump integrity but also extend their lifespan, assuring users of their investment. Trustworthiness in screw slurry pump systems is further underscored by their eco-friendly operations. Compared to traditional pumping methods, screw pumps have lower energy consumption, thanks to their ability to minimize friction losses. This energy efficiency doesn't just lower operational costs but also contributes to a reduced carbon footprint, aligning with growing environmental conservation efforts. Furthermore, screw slurry pumps are known for their quiet operation. The smooth flow generated by the helical design reduces noise pollution, an often-overlooked advantage that enhances workplace environments, ensuring compliance with occupational health standards and promoting worker safety and satisfaction. For industries looking for reliable, efficient, and cost-effective slurry handling solutions, the screw slurry pump stands out as the product of choice. With its established performance record, backed by extensive engineering know-how, this pump type not only meets but exceeds the ever-growing demands of modern industry sectors. Ultimately, investing in a screw slurry pump equates to a commitment to quality and efficiency, principles that are crucial to maintaining competitiveness in today's fast-evolving markets. Their enduring design and operational benefits make them an invaluable component of any organization looking to optimize their fluid handling processes.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024