-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 24, 2025 01:16

Back to list

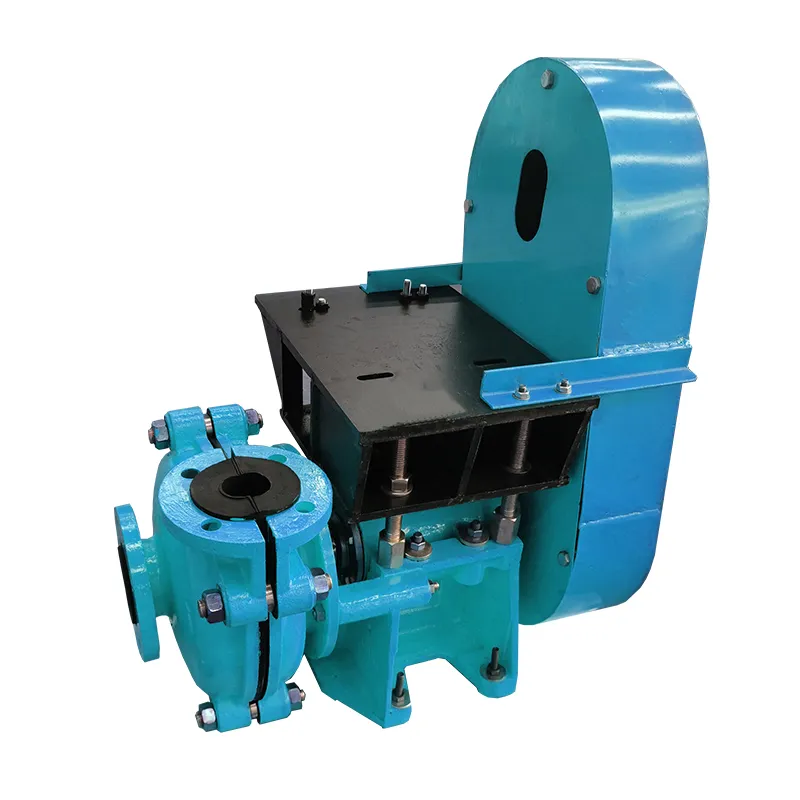

screw slurry pump

Selecting a screw slurry pump can significantly enhance the efficiency and reliability of fluid handling applications across various industries. These pumps are renowned for their superior handling of viscous, abrasive, and solid-laden fluids, making them an indispensable tool in sectors such as mining, wastewater treatment, and chemical processing.

In terms of environmental impact, screw slurry pumps contribute to sustainability objectives by ensuring efficient energy consumption. Their design reduces friction and wear, which translates into lower energy requirements compared to conventional pumping systems. This efficiency not only fulfills regulatory compliance but also aligns with global sustainability efforts aimed at reducing industrial energy footprints. Moreover, collaborating with reputable manufacturers ensures access to technical support and expertise essential in optimizing pump performance. Such partnerships provide a wealth of resources, from technical documentation to onsite training, enhancing the overall operational proficiency of the utilizing teams. In choosing a screw slurry pump, reliance on expert guidance is paramount. Industry professionals and engineers possess the specialized knowledge required to navigate the complexities of pump selection and integration, ensuring that every aspect is tailored to the specific needs of an operation. This expert input not only mitigates risks associated with improper pump selection but also fortifies trust in the system's reliability. The trustworthiness of screw slurry pumps is well-documented through extensive case studies and field reports illustrating their robust performance in demanding situations. Industries worldwide have consistently reported positive outcomes, underscoring the pump's role as a critical component in their fluid management systems. By investing in a screw slurry pump, businesses secure a blend of reliability, efficiency, and adaptability, crucial in maintaining competitive advantages in today's fast-paced industrial environment. As industries continue to evolve, the need for advanced, trustworthy fluid handling solutions like the screw slurry pump will undoubtedly remain at the forefront of operational innovation.

In terms of environmental impact, screw slurry pumps contribute to sustainability objectives by ensuring efficient energy consumption. Their design reduces friction and wear, which translates into lower energy requirements compared to conventional pumping systems. This efficiency not only fulfills regulatory compliance but also aligns with global sustainability efforts aimed at reducing industrial energy footprints. Moreover, collaborating with reputable manufacturers ensures access to technical support and expertise essential in optimizing pump performance. Such partnerships provide a wealth of resources, from technical documentation to onsite training, enhancing the overall operational proficiency of the utilizing teams. In choosing a screw slurry pump, reliance on expert guidance is paramount. Industry professionals and engineers possess the specialized knowledge required to navigate the complexities of pump selection and integration, ensuring that every aspect is tailored to the specific needs of an operation. This expert input not only mitigates risks associated with improper pump selection but also fortifies trust in the system's reliability. The trustworthiness of screw slurry pumps is well-documented through extensive case studies and field reports illustrating their robust performance in demanding situations. Industries worldwide have consistently reported positive outcomes, underscoring the pump's role as a critical component in their fluid management systems. By investing in a screw slurry pump, businesses secure a blend of reliability, efficiency, and adaptability, crucial in maintaining competitive advantages in today's fast-paced industrial environment. As industries continue to evolve, the need for advanced, trustworthy fluid handling solutions like the screw slurry pump will undoubtedly remain at the forefront of operational innovation.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024