-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 12:53

Back to list

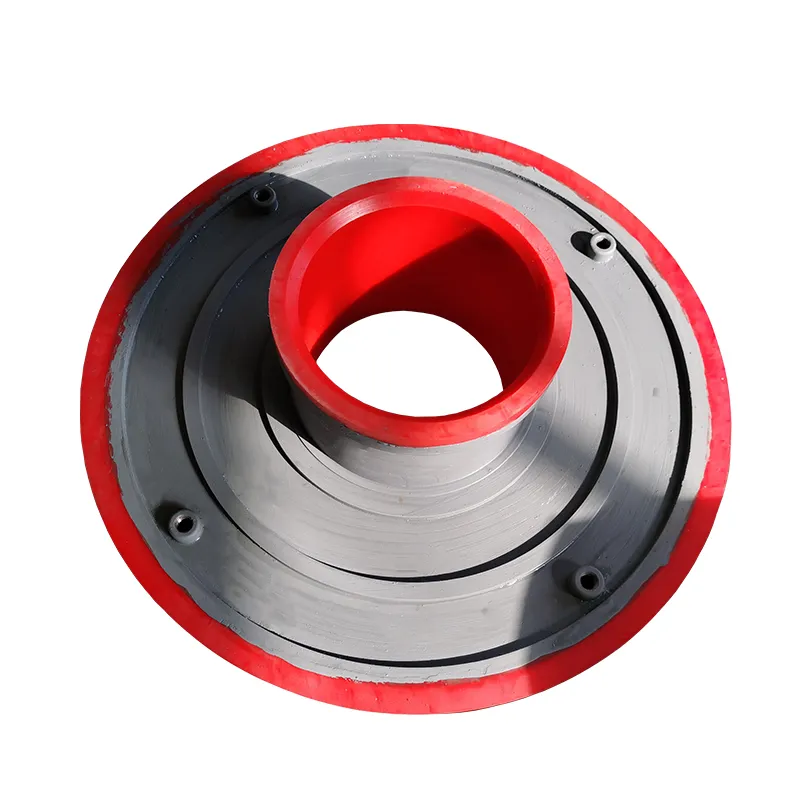

Pump Wear Parts G8041 Metal

Sand casting impellers is a fundamental process used across industries to create complex parts for diverse applications. This method is particularly favored for producing impellers due to its cost-effectiveness and the ability to form intricate and precise shapes. Over the years, advancements in sand casting techniques have revolutionized the way impellers are manufactured, leading to innovations that enhance performance, longevity, and efficiency.

Advanced simulation software is increasingly playing a vital role in the design and testing phases of impeller casting. By simulating the fluid dynamics and thermal conditions that the impeller will face, engineers can make necessary adjustments in the casting design to optimize performance. Such simulations allow for the detection and rectification of potential issues like porosity and shrinkage before the actual casting, saving time and resources. Reliability is a key consideration when manufacturing impellers through sand casting. Creating a quality control system that involves rigorous inspection and testing of the cast pieces ensures that only impellers meeting stringent standards are passed for operation. X-ray inspection, ultrasonic testing, and 3D scanning technologies are commonly used to detect any internal or external defects, ensuring that each impeller leaves the facility ready to deliver optimal performance. Today's industry demands have further pushed innovations in the sand casting of impellers, introducing smart manufacturing processes. The integration of IoT and AI-driven data analytics in sand casting processes is emerging as a new trend. These technologies help monitor casting conditions in real time, offering predictive insights to preemptively address defects, thus increasing yield rates and reducing waste. Trustworthiness in sand casting impeller production is enhanced by adhering to international quality standards. Certifications like ISO 9001 are not just a credential but a commitment to manufacturing excellence. For customers, these certifications translate to a guarantee that the impellers are produced under strict quality control measures, ensuring reliability and performance in demanding operational environments. In conclusion, sand casting impellers is a sophisticated domain requiring thorough understanding and expertise to deliver high-quality products. It combines traditional techniques with cutting-edge technology to meet modern-day challenges successfully. Mastery over this craft ensures that the final product is not only efficient and reliable but also enhances the overall energy efficiency and productivity of the machines they run in. This focus on precision, quality, and innovation continues to solidify sand casting's position as a preferred method for producing high-performance impellers.

Advanced simulation software is increasingly playing a vital role in the design and testing phases of impeller casting. By simulating the fluid dynamics and thermal conditions that the impeller will face, engineers can make necessary adjustments in the casting design to optimize performance. Such simulations allow for the detection and rectification of potential issues like porosity and shrinkage before the actual casting, saving time and resources. Reliability is a key consideration when manufacturing impellers through sand casting. Creating a quality control system that involves rigorous inspection and testing of the cast pieces ensures that only impellers meeting stringent standards are passed for operation. X-ray inspection, ultrasonic testing, and 3D scanning technologies are commonly used to detect any internal or external defects, ensuring that each impeller leaves the facility ready to deliver optimal performance. Today's industry demands have further pushed innovations in the sand casting of impellers, introducing smart manufacturing processes. The integration of IoT and AI-driven data analytics in sand casting processes is emerging as a new trend. These technologies help monitor casting conditions in real time, offering predictive insights to preemptively address defects, thus increasing yield rates and reducing waste. Trustworthiness in sand casting impeller production is enhanced by adhering to international quality standards. Certifications like ISO 9001 are not just a credential but a commitment to manufacturing excellence. For customers, these certifications translate to a guarantee that the impellers are produced under strict quality control measures, ensuring reliability and performance in demanding operational environments. In conclusion, sand casting impellers is a sophisticated domain requiring thorough understanding and expertise to deliver high-quality products. It combines traditional techniques with cutting-edge technology to meet modern-day challenges successfully. Mastery over this craft ensures that the final product is not only efficient and reliable but also enhances the overall energy efficiency and productivity of the machines they run in. This focus on precision, quality, and innovation continues to solidify sand casting's position as a preferred method for producing high-performance impellers.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024