-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 04:40

Back to list

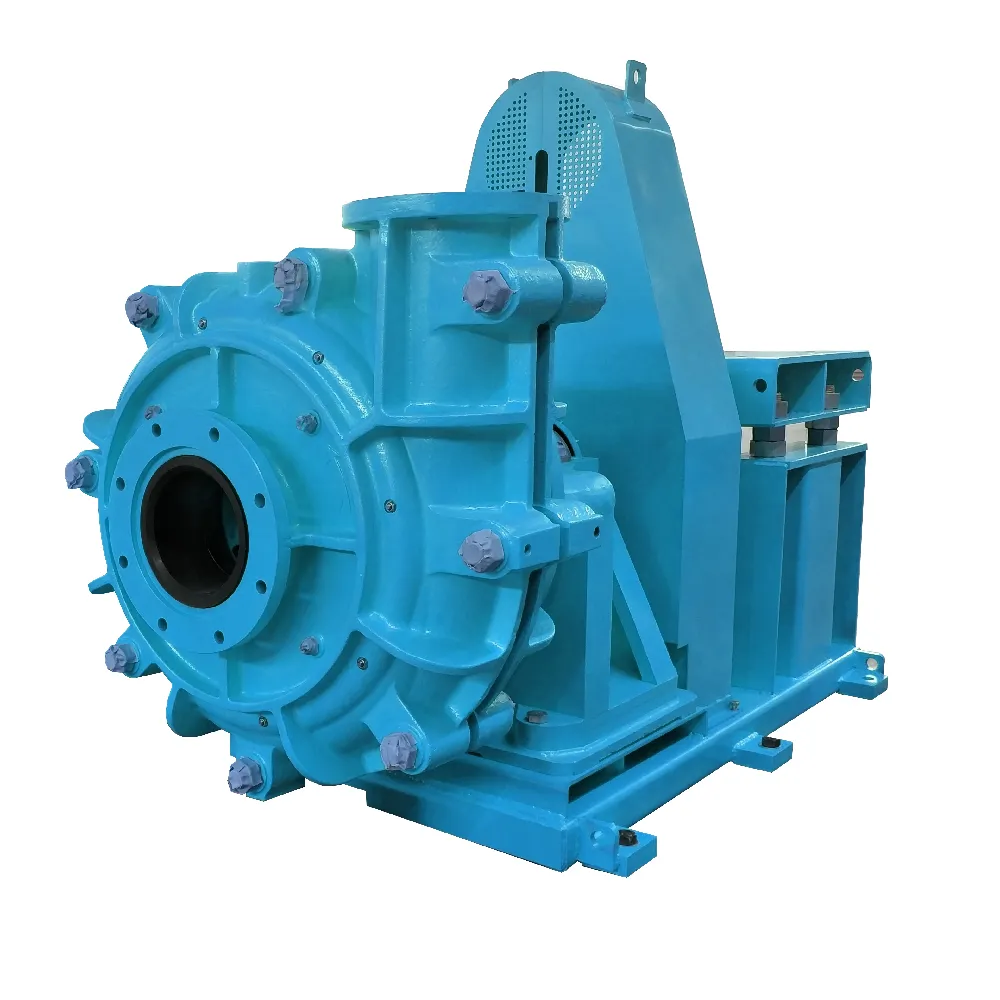

pump volute meaning

The term pump volute is integral to the design and functionality of centrifugal pumps, often influencing their efficiency and performance in various industrial applications. A pump volute is essentially the casing portion of a centrifugal pump that collects the fluid from the impeller and directs it towards the pump discharge. Understanding its meaning and role is crucial for both engineers and procurement professionals who aim to optimize their systems for better fluid dynamics, energy efficiency, and reliability.

The authority of the pump volute's design is grounded in its scientific basis and the stringent adherence to engineering standards. Manufacturers and industry experts rely on computational fluid dynamics (CFD) simulations to fine-tune volute designs. This advanced tool allows for precise modeling of fluid flows, helping engineers predict how the pump volute will perform under different conditions. Such technologically sophisticated methods build trust with end-users, as they assure that each pump component has been optimized for peak performance. Beyond technical specifics, a trustworthy perspective on pump volutes considers the materials used in their construction. Different applications require varying levels of resistance to temperature, pressure, and corrosive substances. For example, stainless steel volutes might be preferable in environments where corrosion resistance is paramount, whereas ductile iron could be sufficient for less demanding operations. Knowledge of material properties and their compatibility with specific fluids ensures that volutes operate reliably over time. Ensuring that pump volutes meet regulatory and industry standards further reinforces their authoritativeness and trustworthiness. Compliance with ISO and ANSI standards not only guarantees that the volute performs as expected but also provides a competitive advantage in global markets that increasingly prioritize standardization and quality assurance. In conclusion, the meaning and importance of a pump volute extend far beyond its basic definition. Its design, material selection, and compliance with standards collectively influence a centrifugal pump’s efficiency, reliability, and sustainability. Professionals equipped with both experience and expertise are best positioned to select and maintain pump volutes that meet specific operational requirements, ensuring long-term performance and cost efficiency. With the ever-growing demand for efficient and reliable fluid handling systems, a comprehensive understanding of pump volutes is indispensable for industry success.

The authority of the pump volute's design is grounded in its scientific basis and the stringent adherence to engineering standards. Manufacturers and industry experts rely on computational fluid dynamics (CFD) simulations to fine-tune volute designs. This advanced tool allows for precise modeling of fluid flows, helping engineers predict how the pump volute will perform under different conditions. Such technologically sophisticated methods build trust with end-users, as they assure that each pump component has been optimized for peak performance. Beyond technical specifics, a trustworthy perspective on pump volutes considers the materials used in their construction. Different applications require varying levels of resistance to temperature, pressure, and corrosive substances. For example, stainless steel volutes might be preferable in environments where corrosion resistance is paramount, whereas ductile iron could be sufficient for less demanding operations. Knowledge of material properties and their compatibility with specific fluids ensures that volutes operate reliably over time. Ensuring that pump volutes meet regulatory and industry standards further reinforces their authoritativeness and trustworthiness. Compliance with ISO and ANSI standards not only guarantees that the volute performs as expected but also provides a competitive advantage in global markets that increasingly prioritize standardization and quality assurance. In conclusion, the meaning and importance of a pump volute extend far beyond its basic definition. Its design, material selection, and compliance with standards collectively influence a centrifugal pump’s efficiency, reliability, and sustainability. Professionals equipped with both experience and expertise are best positioned to select and maintain pump volutes that meet specific operational requirements, ensuring long-term performance and cost efficiency. With the ever-growing demand for efficient and reliable fluid handling systems, a comprehensive understanding of pump volutes is indispensable for industry success.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024