-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 07:36

Back to list

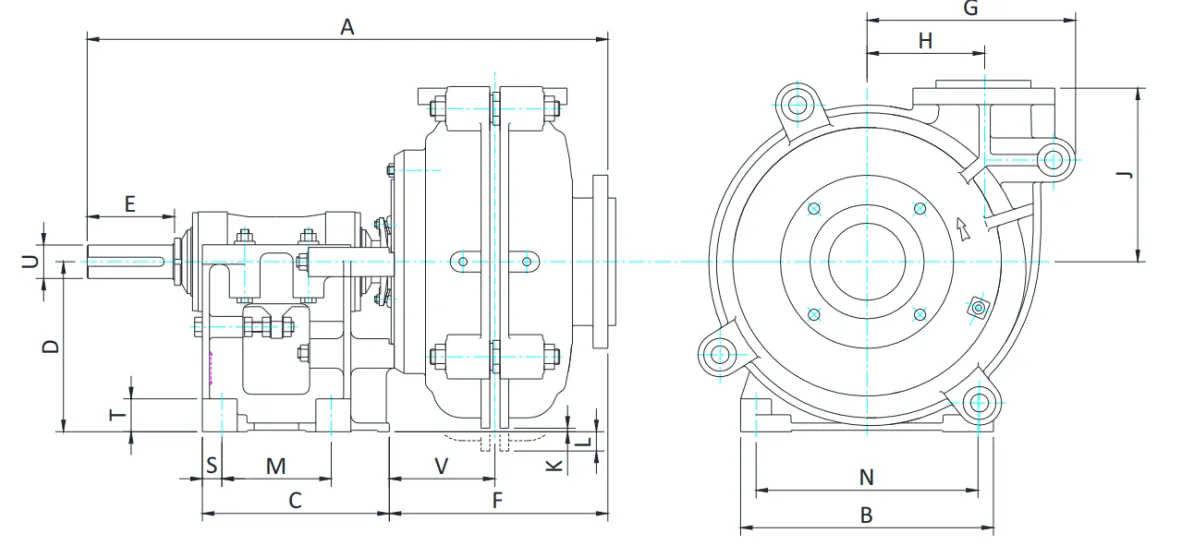

Horizontal Slurry Pumps MM14/12TU-AH

The pump volute—a fundamental component in centrifugal pumps—is often overshadowed by its more illustrious counterparts like the impeller. However, any expert in fluid mechanics will tell you that understanding the intricacies of the pump volute is crucial for optimizing pump performance and ensuring system reliability. As an experienced industry professional, I've spent years immersed in the design and application of pump volutes, and I'm here to share insights that can elevate both your understanding and your system's efficiency.

Let's delve into the actual experience of troubleshooting a pump volute problem. Imagine experiencing frequent issues such as noise, excessive vibration, or unexpected energy bills. These symptoms often indicate that the volute may be at fault. Using tools like computational fluid dynamics (CFD) simulations can unearth invisible flow irregularities. During a recent project, we identified asymmetrical flow through the volute as the root cause of inefficient operation. A redesign with CFD-led optimization improved performance remarkably, reducing power consumption by over 15%. Trust in a product or system begins with understanding its limitations and potential. Enthusiasts, buyers, and engineers should be aware that pump volutes are not one-size-fits-all. For example, a volute designed for high-capacity industrial use may not align with the needs of a small-scale agricultural operation. It's essential to evaluate the system requirements fully before settling on a pump design to ensure cost-efficiency and reliability. As an authority in the field, I can affirm that collaborative efforts among manufacturers, engineers, and end-users are pivotal in crafting volute designs that meet diverse operational demands. Staying informed about the latest developments in volute manufacturing, such as advances in precision casting and 3D printing, will also equip stakeholders to make decisions that enhance system longevity and success. In conclusion, the pump volute occupies a crucial space in the efficient transformation of energy in fluid systems. Its design, material choices, and optimization parameters hold significant sway over the overall pump efficiency and operational lifecycle. Leveraging deep expertise and authoritative insights into volute characteristics will yield better performance, reliability, and trust in your pumping system. Engage in an ongoing dialog within the engineering community and remain vigilant about the latest industry standards and technologies to make informed decisions about pump volute applications.

Let's delve into the actual experience of troubleshooting a pump volute problem. Imagine experiencing frequent issues such as noise, excessive vibration, or unexpected energy bills. These symptoms often indicate that the volute may be at fault. Using tools like computational fluid dynamics (CFD) simulations can unearth invisible flow irregularities. During a recent project, we identified asymmetrical flow through the volute as the root cause of inefficient operation. A redesign with CFD-led optimization improved performance remarkably, reducing power consumption by over 15%. Trust in a product or system begins with understanding its limitations and potential. Enthusiasts, buyers, and engineers should be aware that pump volutes are not one-size-fits-all. For example, a volute designed for high-capacity industrial use may not align with the needs of a small-scale agricultural operation. It's essential to evaluate the system requirements fully before settling on a pump design to ensure cost-efficiency and reliability. As an authority in the field, I can affirm that collaborative efforts among manufacturers, engineers, and end-users are pivotal in crafting volute designs that meet diverse operational demands. Staying informed about the latest developments in volute manufacturing, such as advances in precision casting and 3D printing, will also equip stakeholders to make decisions that enhance system longevity and success. In conclusion, the pump volute occupies a crucial space in the efficient transformation of energy in fluid systems. Its design, material choices, and optimization parameters hold significant sway over the overall pump efficiency and operational lifecycle. Leveraging deep expertise and authoritative insights into volute characteristics will yield better performance, reliability, and trust in your pumping system. Engage in an ongoing dialog within the engineering community and remain vigilant about the latest industry standards and technologies to make informed decisions about pump volute applications.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024