-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 05:22

Back to list

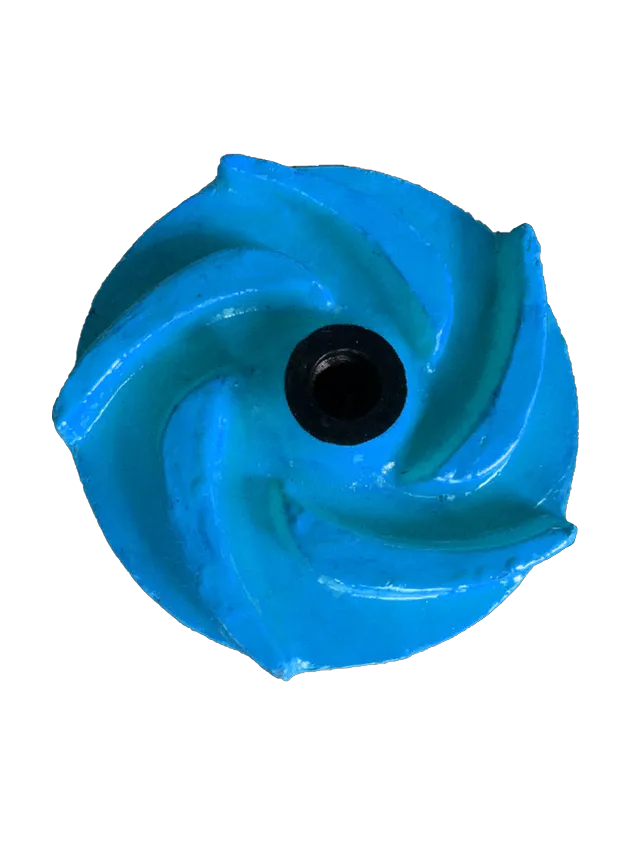

pump impeller types and applications

Pump impellers are a critical component in the design and operation of various types of pumps used across numerous industries. These rotating mechanisms are responsible for transferring energy from the motor, moving the fluid by converting rotational kinetic energy to hydrodynamic energy of fluid flow. Understanding the different types of pump impellers and their specific applications can significantly enhance operational efficiency and service life, making it an essential focus for industries seeking optimization and innovation in fluid management systems.

Another specialization is found in radial flow impellers, which provide high pressure at low flow rates. These are often utilized in wastewater treatment, chemical processing, and mining industries where compact yet powerful pumping solutions are necessary. Their high-pressure output can efficiently handle the demands of distribution systems where the fluid must be transported over long distances or against substantial force differentials. An emerging trend in the pump impeller industry is the adoption of composite materials that enhance device longevity and performance under harsh conditions. Advanced materials such as reinforced polymers and engineered ceramics are being utilized to create impellers that withstand higher temperatures, corrosive chemicals, and abrasive particles, expanding their applicability and reliability in more extreme environments. The advent of computational fluid dynamics (CFD) has also revolutionized the design and optimization of pump impellers. By simulating fluid flow within the impeller and through the pump, engineers can fine-tune impeller geometry to maximize efficiency and minimize energy consumption. This technology facilitates the customization of impellers tailored explicitly to the operational needs, optimizing them for unique challenges presented across industries. As industries evolve and the demand for more efficient, resilient, and durable pumping solutions rises, the development and application of advanced pump impellers continue to advance. End-users are encouraged to consult with pump specialists to identify the most suitable impeller type for their specific needs, ensuring optimal performance and longevity in their fluid management systems. By aligning with innovative designs and materials, industries can achieve greater sustainability and operational efficiency in their fluid transport tasks.

Another specialization is found in radial flow impellers, which provide high pressure at low flow rates. These are often utilized in wastewater treatment, chemical processing, and mining industries where compact yet powerful pumping solutions are necessary. Their high-pressure output can efficiently handle the demands of distribution systems where the fluid must be transported over long distances or against substantial force differentials. An emerging trend in the pump impeller industry is the adoption of composite materials that enhance device longevity and performance under harsh conditions. Advanced materials such as reinforced polymers and engineered ceramics are being utilized to create impellers that withstand higher temperatures, corrosive chemicals, and abrasive particles, expanding their applicability and reliability in more extreme environments. The advent of computational fluid dynamics (CFD) has also revolutionized the design and optimization of pump impellers. By simulating fluid flow within the impeller and through the pump, engineers can fine-tune impeller geometry to maximize efficiency and minimize energy consumption. This technology facilitates the customization of impellers tailored explicitly to the operational needs, optimizing them for unique challenges presented across industries. As industries evolve and the demand for more efficient, resilient, and durable pumping solutions rises, the development and application of advanced pump impellers continue to advance. End-users are encouraged to consult with pump specialists to identify the most suitable impeller type for their specific needs, ensuring optimal performance and longevity in their fluid management systems. By aligning with innovative designs and materials, industries can achieve greater sustainability and operational efficiency in their fluid transport tasks.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024