-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

pump impeller selection

Selecting the Right Pump Impeller A Comprehensive Guide

When it comes to fluid transfer systems, the pump impeller plays a crucial role in determining the efficiency and effectiveness of the entire system. The impeller is essentially the heart of the pump, responsible for converting mechanical energy into hydraulic energy. Therefore, selecting the right impeller is critical for maintaining performance, reliability, and longevity in various industrial applications.

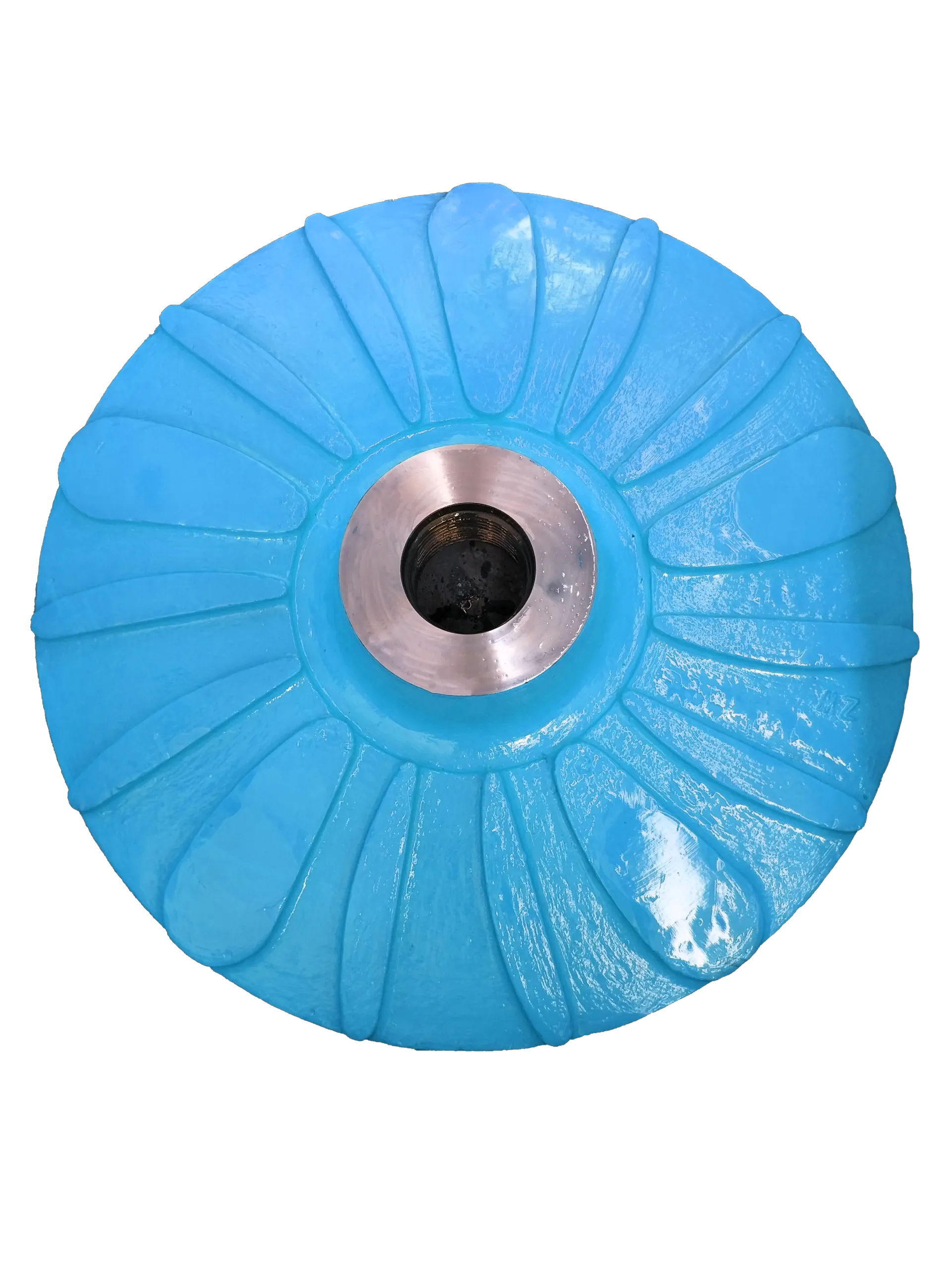

Understanding Pump Impellers

Before diving into the selection process, it’s important to understand what an impeller is and how it functions. An impeller consists of a rotating set of blades, which accelerate the fluid outwards, increasing its pressure and flow rate. There are various types of impellers tailored for specific applications, including closed, semi-open, and open impellers. Each type has its unique advantages and disadvantages depending on the fluid characteristics and operational demands.

Key Factors in Impeller Selection

1. Fluid Characteristics - Viscosity The viscosity of the fluid can significantly affect the impeller's performance. Higher viscosity fluids may require impellers designed for greater lift and efficiency to manage the increased resistance. - Corrosiveness If the fluid is corrosive, selecting an impeller made from suitable materials, such as stainless steel or specialized alloys, is essential to avoid rapid wear and failure. - Temperature High-temperature fluids can impact both the material choice and the design of the impeller. High-performance materials might be necessary to withstand thermal stress.

2. Flow Rate and Head Requirements - Understanding the required flow rate and head pressure is vital for an effective selection. Different impeller designs produce varying flow characteristics; therefore, matching the impeller type to the desired flow and head specifications is essential. Closed impellers are generally more efficient for achieving high head pressures, whereas open impellers can handle large solid particles at the expense of efficiency.

pump impeller selection

3. Operating Conditions - Speed The operating speed of the impeller (RPM) can influence performance. Higher speeds typically lead to greater flow rates but might also introduce issues like cavitation or excessive wear in certain fluid conditions. - System Design The overall system layout can also dictate impeller choice. For instance, systems with tight tolerances may require the precision of closed impellers to avoid leakage and maintain efficiency.

4. Application Type - Industrial vs. Municipal Uses Industrial applications often involve more abrasive or viscous fluids that require robust impeller designs. In contrast, municipal applications may prioritize efficiency and standard designs, as the nature of the fluid is typically less variable. - Continuous vs. Intermittent Operation Impellers used in continuous operations need to be designed for durability, while those for intermittent use can focus more on peak performance during short cycles.

Performance Metrics

When selecting an impeller, considering performance metrics is crucial. Look into the pump curve, which illustrates the relationship between flow rate and head across different impeller designs. Identifying the best-fit impeller for your specific performance requirements can save energy and increase operational efficiency, leading to reduced operational costs over time.

Conclusion

Selecting the right pump impeller is a multifaceted process that requires thorough consideration of several factors, including fluid characteristics, performance requirements, operating conditions, and specific applications. By understanding these elements and how they relate to impeller design, operators can make informed choices that enhance pump performance and reliability. Investing time in the selection process not only mitigates potential issues down the line but also optimizes overall system efficiency, making it a critical aspect of pump management. Whether in industrial, municipal, or any other context, a well-chosen impeller serves as the backbone of efficient fluid transfer.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024